Preparation method for bioactive ceramic membrane on surface of tantalum metal

A bioactive ceramic and metal surface technology, applied in surface reaction electrolytic coatings, electrolytic coatings, coatings, etc., can solve the problem of poor metal bioactivity and osteoinductive ability, low bonding strength between film and matrix, and inability to generate bone bonds In order to improve biocompatibility and biological activity, improve biocompatibility, and promote the effect of combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

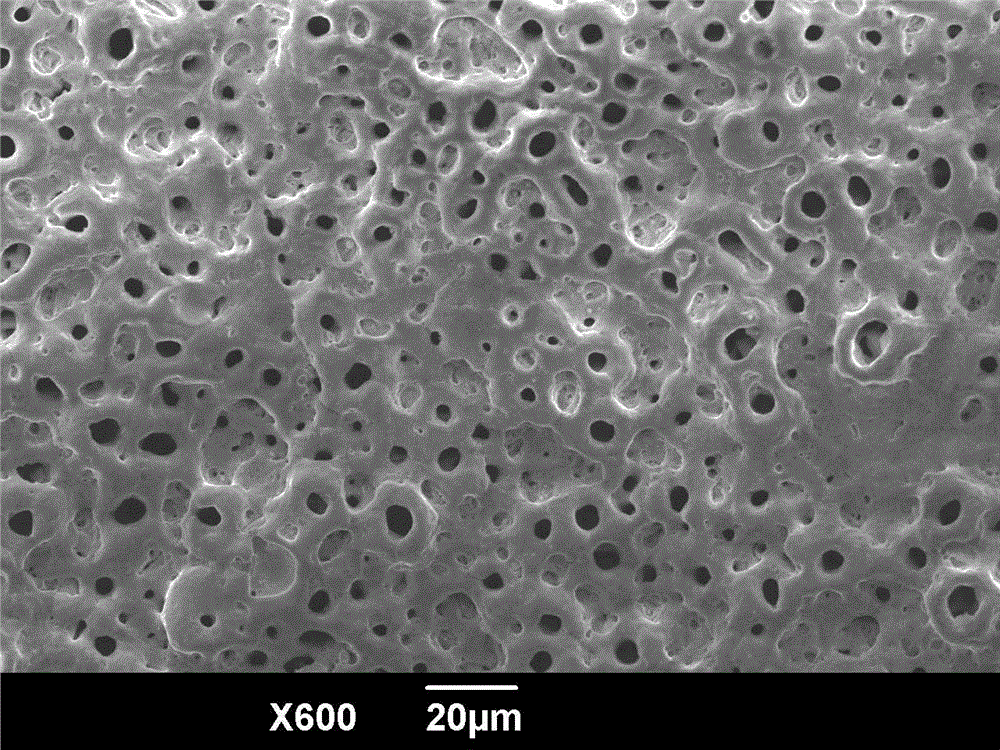

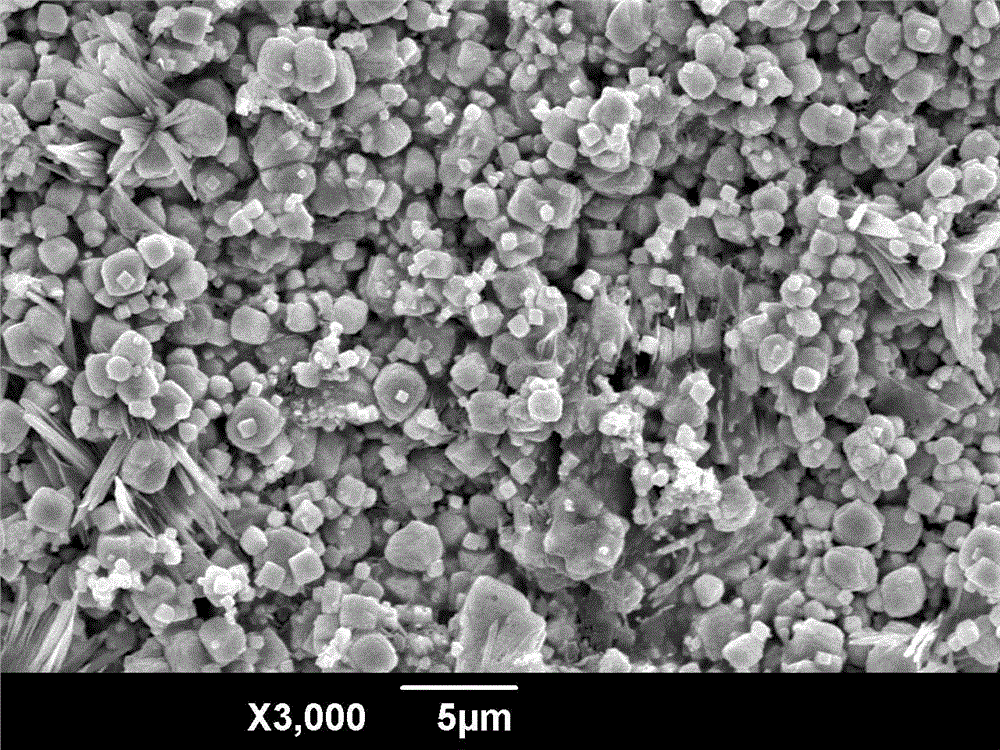

[0014] Specific Embodiment 1: In this embodiment, the preparation method of bioactive ceramic film on the surface of tantalum metal is realized through the following steps: 1. Carry out deoxidation film and degreasing treatment on tantalum metal in sequence; 2. Prepare electrolyte: 8-95g / L of anhydrous calcium acetate, 3-28g / L of disodium hydrogen phosphate dodecahydrate, 1-5g / L of disodium ethylenediaminetetraacetate, the solvent is deionized water; The metal is the anode, which is fixed with a fixture and immersed in the electrolyte configured in step 2. The stainless steel electrolyte tank is the cathode, and the pulse power supply is used. The electrical parameters are set as follows: pulse voltage 210-460V, pulse frequency 300-600Hz, duty cycle 10- 50%, carry out micro-arc oxidation for 5-30min; 4. Put the tantalum metal treated in step 3 into the hydrothermal autoclave, then raise the temperature to 300-600°C at a heating rate of 2-8°C / min, and keep it warm 5-8h, contro...

specific Embodiment approach 2

[0015] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the tantalum metal is sequentially deoxidized and degreased: 100#, 200#, 300#, 500#, 800#, Use 1000#, 1200#, 1500#, 2000# sandpaper to polish to remove the oxide film, then wash with acetone to remove surface oil, then ultrasonically clean with deionized water, and dry naturally.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the electrolyte is prepared in step two: 32-63g / L anhydrous calcium acetate, 7-15g / L disodium hydrogen phosphate dodecahydrate, 2-4g / L disodium ethylenediamine tetraacetate, the solvent is deionized water, and other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com