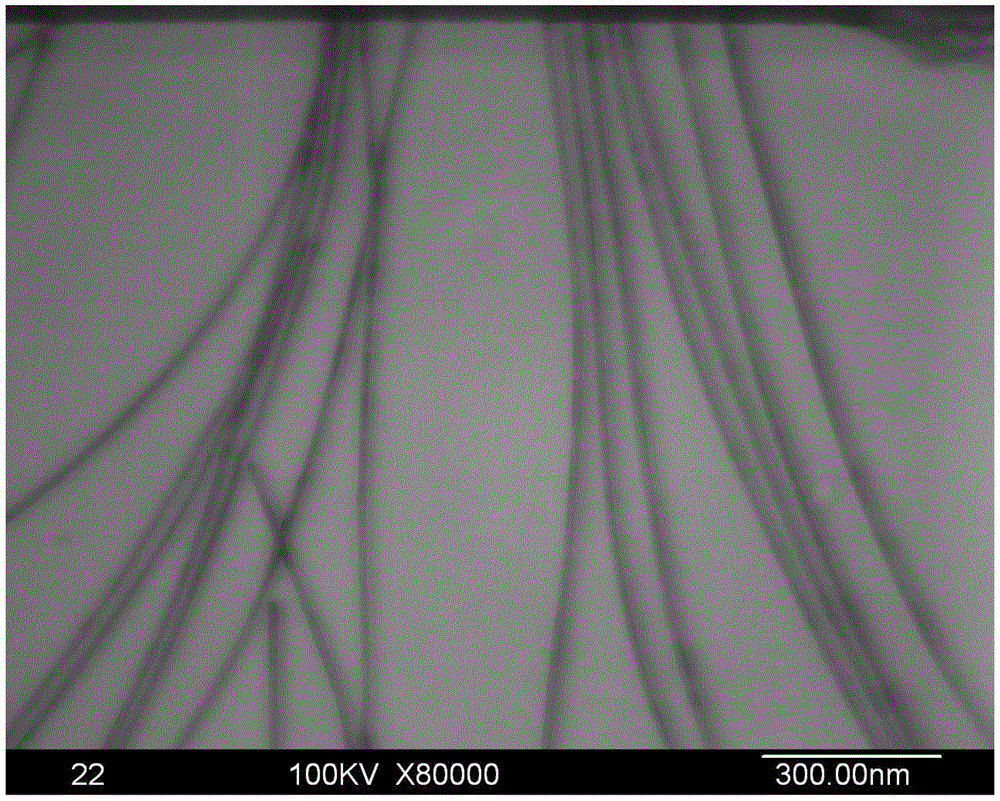

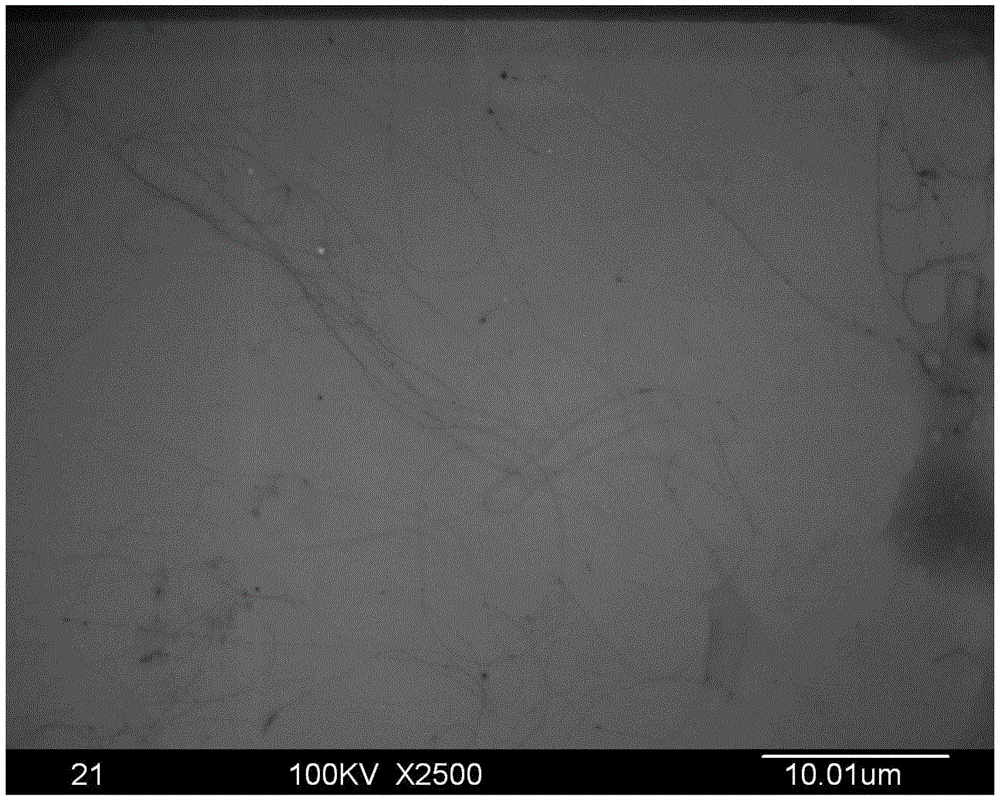

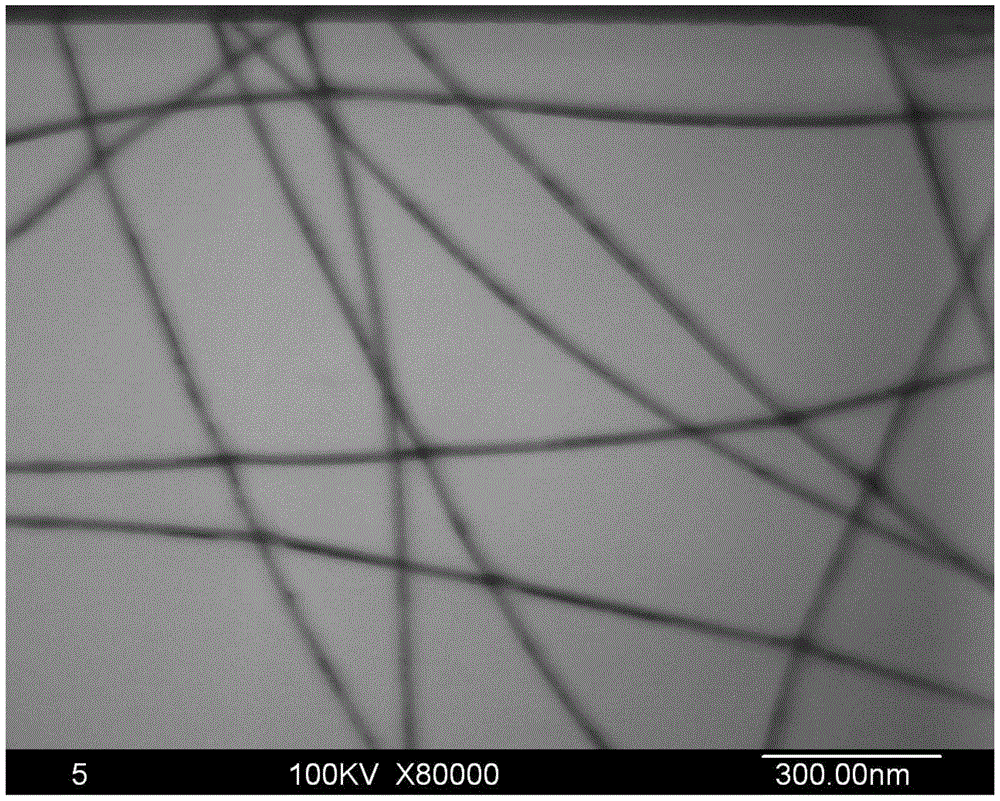

A preparation process of silver nanowires with fine diameter and high aspect ratio

A high aspect ratio, silver nanowire technology, applied in the field of nanomaterials, can solve the problem that the long diameter and the thin diameter of the silver nanowire cannot be taken into account, and achieve the effects of high aspect ratio, simple preparation method and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Glucose is dissolved in pure water to prepare an aqueous glucose solution with a concentration of 0.05mol / L, which is the reducing agent solution A;

[0036] 2) Dissolve polyvinylpyrrolidone and polyvinyl alcohol in pure water at a molar ratio of 1:1 to prepare an aqueous solution of polyvinylpyrrolidone with a concentration of 0.25 mol / L, which is template solution B;

[0037] 3) Mix 130ml of solution A with 130ml of solution B, stir evenly to obtain reaction mother liquor D;

[0038] 4) Dissolve silver nitrate in purified water to prepare a silver nitrate aqueous solution with a concentration of 0.1 mol / L, which is silver nitrate solution C.

[0039] 5) Tetrabutylammonium chloride is dissolved in pure water to prepare a tetrabutylammonium chloride aqueous solution with a concentration of 0.01mol / L, which is the inducer solution E;

[0040] 6) Take 0.1ml polyvinylpyrrolidone solution B, 16ml sodium citrate (0.05mol / L), 1.5ml ferric chloride (0.005mol / L), 1.5ml L-ar...

Embodiment 2

[0045] 1) Glucose is dissolved in pure water to prepare an aqueous glucose solution with a concentration of 0.1mol / L, which is the reducing agent solution A;

[0046] 2) Polyvinylpyrrolidone is dissolved in pure water to prepare an aqueous solution of polyvinylpyrrolidone with a concentration of 0.25mol / L, which is template solution B;

[0047] 3) Mix 350ml reducing agent solution A with 550ml template solution B, stir evenly to obtain reaction mother solution D;

[0048]4) adopt silver nitrate to be dissolved in pure water, be mixed with the silver nitrate aqueous solution that concentration is 0.1mol / L, be silver nitrate solution C;

[0049] 5) Dissolve cetyltrimethylammonium bromide in purified water to prepare a cetyltrimethylammonium bromide aqueous solution with a concentration of 0.01mol / L, which is inducer solution E;

[0050] 6) Take 0.1ml polyvinylpyrrolidone template solution B, 16ml sodium citrate aqueous solution (0.05mol / L), 1.5ml ferric chloride (0.005mol / L), 1...

Embodiment 3

[0055] 1) Glucose is dissolved in pure water to prepare an aqueous glucose solution with a concentration of 0.05mol / L, which is the reducing agent solution A;

[0056] 2) Polyvinylpyrrolidone was dissolved in pure water to prepare an aqueous solution of polyvinylpyrrolidone with a concentration of 0.2 mol / L, which was template solution B;

[0057] 3) Mix 15L of reducing agent solution A with 22L of template solution B, stir evenly to obtain reaction mother solution D;

[0058] 4) Dissolve silver nitrate in purified water to prepare a silver nitrate aqueous solution with a concentration of 0.03 mol / L, which is silver nitrate solution C.

[0059] 5) Sodium chloride is dissolved in pure water to prepare a sodium chloride solution with a concentration of 0.05mol / L, which is the inducer solution E;

[0060] 6) Take 0.13ml polyvinylpyrrolidone aqueous template solution B, 16ml sodium citrate aqueous solution (0.05mol / L), 1.5ml ferric chloride (0.005mol / L), 1.5ml arginine (0.005mol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com