Preparation method of fermented flavored perilla frutescens paste

A technology for fermenting flavor and basil sauce, applied in food preparation, application, food science and other directions, can solve the problems of waste of beneficial substances and not being well utilized, and achieve vigorous growth, increase nutrition and flavor, and easy production conditions. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

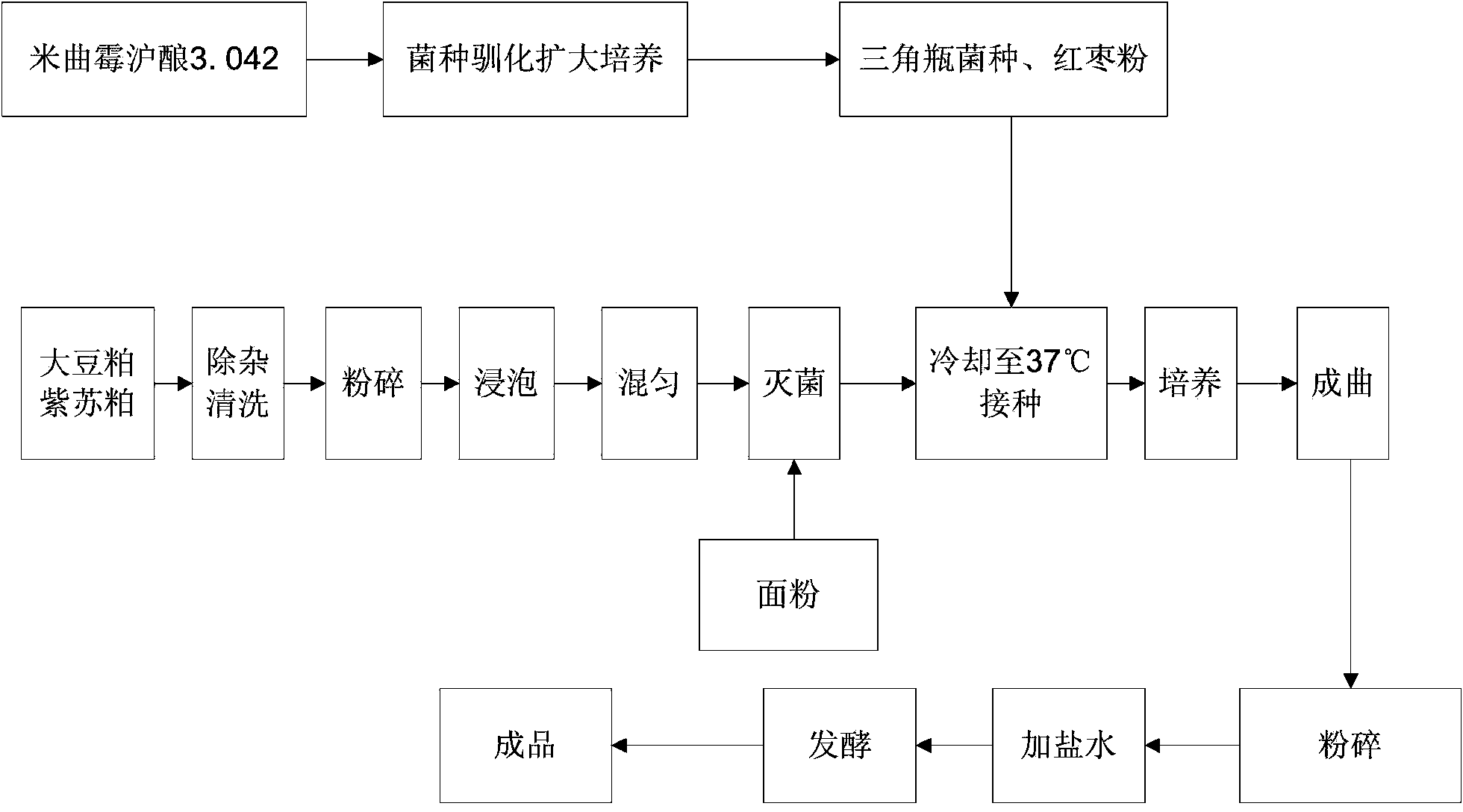

Image

Examples

Embodiment 1

[0026] The raw materials of fermented perilla sauce are perilla meal, soybean meal, flour and jujube powder, with a mass ratio of 5:5:2:0.1. The preparation process of fermented perilla sauce is as follows:

[0027] Step 1. Raw material preparation

[0028] Mix perilla meal and soybean meal evenly in a ratio of 5:5, then add warm water at 40°C to soak for 8 hours, mix well, and sterilize at 121°C for 30 minutes. When the temperature of the material drops to 100°C, add flour on the surface of the koji material, and cover the pot Use waste heat to keep warm naturally.

[0029] Step 2. Strain acclimatization

[0030] Take 70g of bean powder ground into 100 mesh, 10g of perilla meal powder ground into 100 mesh, 20g of red date powder, 10g of glucose, KH 2 PO 4 1g, MgSO 4 0.5g, (NH 4 ) 2 SO 4 0.5g, 18g agar, 1000mL water, natural pH value; sterilize at 121°C for 25 minutes to make soybean flour seed medium; irradiate the spore suspension of Aspergillus oryzae Huyao 3.042 un...

Embodiment 2

[0039] The raw materials of fermented perilla sauce are perilla meal, soybean meal, flour and jujube powder, with a mass ratio of 4:6:3:0.08. The preparation process of fermented perilla sauce is as follows:

[0040] Step 1. Raw material preparation

[0041] Mix perilla meal and soybean meal in a ratio of 4:6, then add warm water at 40°C to soak for 8 hours, mix well, and sterilize at 121°C for 30 minutes. When the temperature of the material drops to 100°C, add flour on the surface of the koji material, and cover the pot Use waste heat to keep warm naturally.

[0042] Step 2. Strain acclimatization

[0043] Take 70g of soybean powder ground into 100 mesh, 10g of perilla meal powder ground into 100 mesh, 20g of red date powder, 10g of glucose, KH 2 PO 4 1g, MgSO 4 0.5g, (NH 4 ) 2 SO 4 0.5g, 18g agar, 1000mL water, natural pH value; sterilize at 121°C for 25 minutes to make soybean flour seed medium; irradiate the spore suspension of Aspergillus oryzae Huyao 3.042 under...

Embodiment 3

[0052] The raw materials of fermented perilla sauce are perilla meal, soybean meal, flour and jujube powder, with a mass ratio of 3:7:3:0.1. The preparation process of fermented perilla sauce is as follows:

[0053] Step 1. Raw material preparation

[0054] Mix perilla meal and soybean meal evenly in a ratio of 3:7, then add warm water at 40°C to soak for 8 hours, mix well, and sterilize at 121°C for 30 minutes. When the temperature of the material drops to 100°C, add flour on the surface of the koji material, and cover the pot Use waste heat to keep warm naturally.

[0055] Step 2. Strain acclimatization

[0056] Take 70g of soybean powder ground into 100 mesh, 10g of perilla meal powder ground into 100 mesh, 20g of red date powder, 10g of glucose, KH 2 PO 4 1g, MgSO 4 0.5g, (NH 4 ) 2 SO 4 0.5g, 18g agar, 1000mL water, natural pH value; sterilize at 121°C for 25 minutes to make soybean flour seed medium; irradiate the spore suspension of Aspergillus oryzae Huyao 3.042...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com