Preparation method of titaniferous montmorillonite nanocomposite

A nano-composite material, montmorillonite technology, applied in the field of preparation of titanium-containing montmorillonite nano-composite materials, can solve the problems of hindering the diffusion of long-chain hydrocarbons, small pore size, and difficult to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

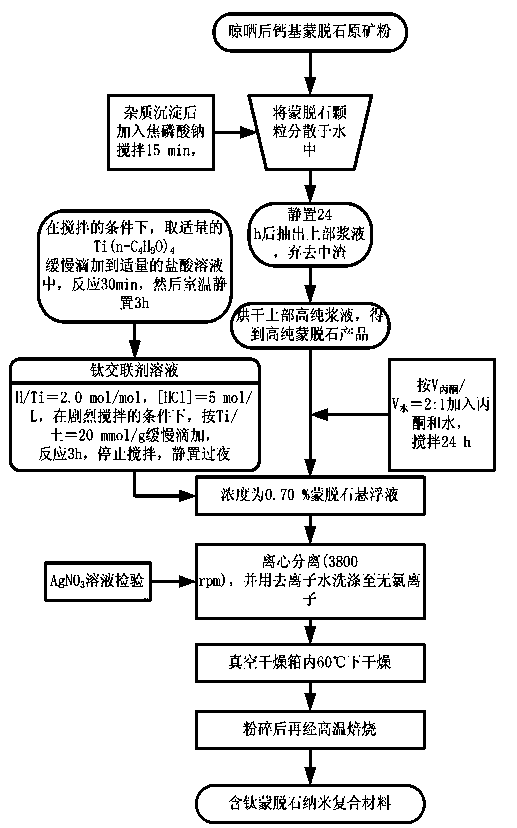

Method used

Image

Examples

example 1

[0025] Example 1: The calcium-based montmorillonite raw ore of a certain place in the east of Hubei, Hubei, is naturally aired, and 30 g of raw ore powder is taken and immersed in 700 ml of water, and the montmorillonite particles are dispersed in water, so that water-insoluble impurities are precipitated, and then Add 1.3 g of sodium pyrophosphate and stir for 15 min. After standing for 24 h, take out the upper slurry and discard the middle residue; dry the upper high-purity slurry to obtain high-purity montmorillonite product. Weigh quantitative high-purity montmorillonite, add acetone and water according to V acetone / V water = 2:1, and make a suspension with a concentration of 0.70% montmorillonite, stir for 24 h, and set aside; under the condition of stirring, take an appropriate amount of Ti(n-C 4 h 9 O) 4 Slowly add it dropwise to an appropriate amount of hydrochloric acid solution, react for 30 min, then stand at room temperature for 3 h, where H / Ti=2.0 mol / mol, [HCl]...

example 2

[0026] Example 2: The calcium-based montmorillonite raw ore is naturally air-dried, and 30 g of raw ore powder is weighed and immersed in 600 ml of water, and the montmorillonite particles are dispersed in water to precipitate water-insoluble impurities, and then add sodium pyrophosphate 1.0 g and stirred for 15 minutes, and after standing for 24 hours, the upper slurry was taken out, and the middle residue was discarded; the upper high-purity slurry was dried to obtain a high-purity montmorillonite product. Weigh quantitative high-purity montmorillonite, add acetone and water according to V acetone / V water = 1.5:1, make a concentration of 0.50% montmorillonite suspension, stir for 24 h, stand-by; under the condition of stirring, take an appropriate amount of Ti(n-C 4 h 9 O) 4 Slowly add it dropwise to an appropriate amount of hydrochloric acid solution, react for 30 min, then stand at room temperature for 3 h, where H / Ti=1.5 mol / mol, [HCl]=4.5 mol / L; under the condition of ...

example 3

[0027] Example 3: The calcium-based montmorillonite raw ore is naturally air-dried, and 30 g of raw ore powder is weighed and immersed in 900 ml of water, and the montmorillonite particles are dispersed in water to precipitate water-insoluble impurities, and then add sodium pyrophosphate 1.5 g and stirred for 15 minutes, and after standing for 24 hours, the upper slurry was taken out, and the middle residue was discarded; the upper high-purity slurry was dried to obtain a high-purity montmorillonite product. Weigh a quantitative amount of high-purity montmorillonite, add acetone and water according to V acetone / V water = 2.5:1, and make a suspension with a concentration of 1.00% montmorillonite, stir for 24 h, and set aside; under stirring conditions, take an appropriate amount of Ti(n-C 4 h 9 O) 4 Slowly add it dropwise to an appropriate amount of hydrochloric acid solution, react for 30 min, then stand at room temperature for 3 h, where H / Ti=2.5 mol / mol, [HCl]=5.5 mol / L; u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com