Preparation method of right-handed rabeprazole sodium monohydrate crystal

A technology for dex-rabeprazole sodium and dex-rabeprazole is applied in the field of preparation of dex-rabeprazole sodium monohydrate crystal, can solve the problems of low yield, low purity and the like, and achieves a simple process , Significant economic value, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

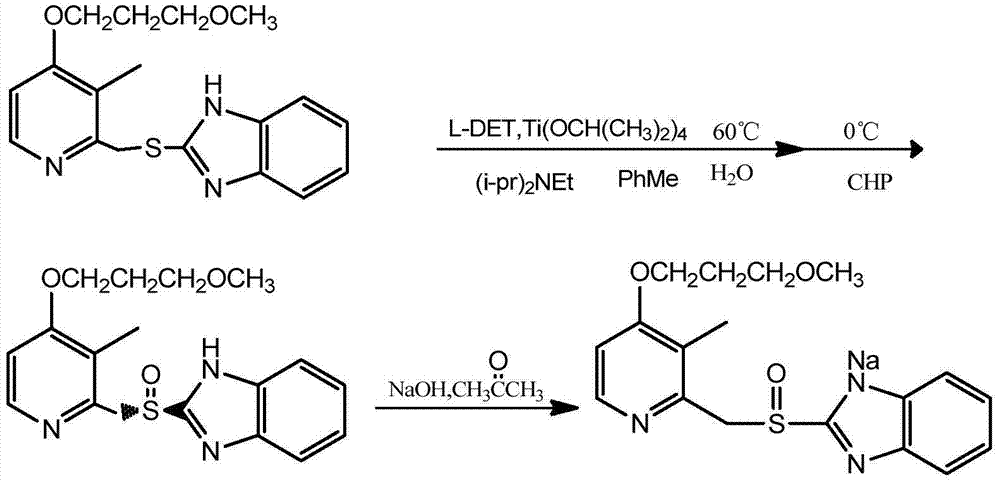

Method used

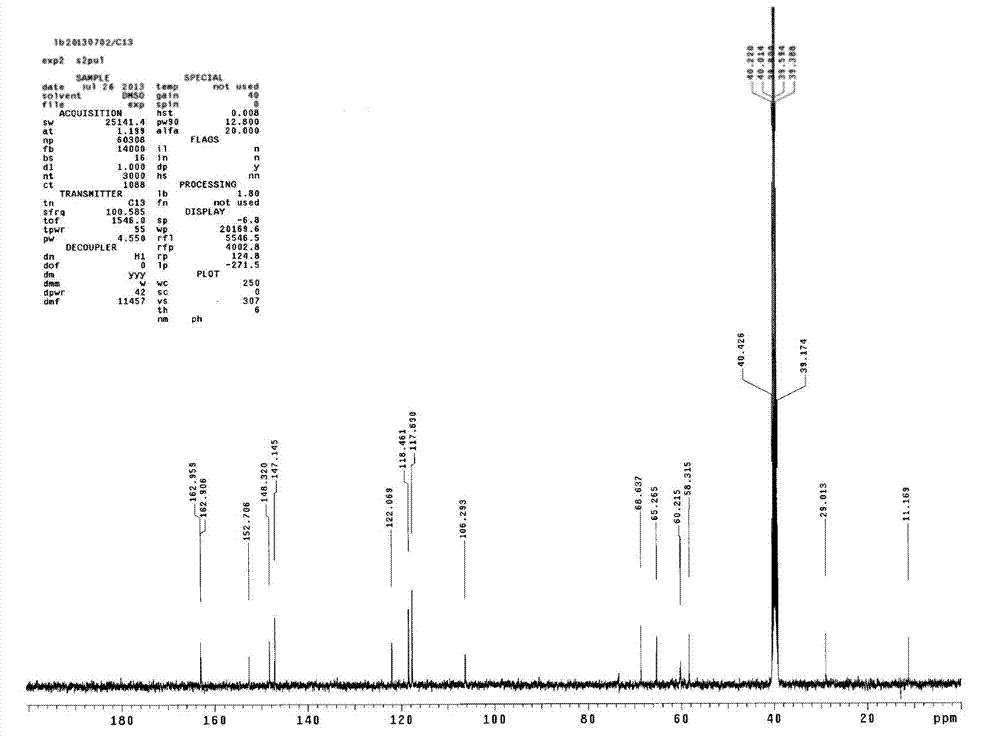

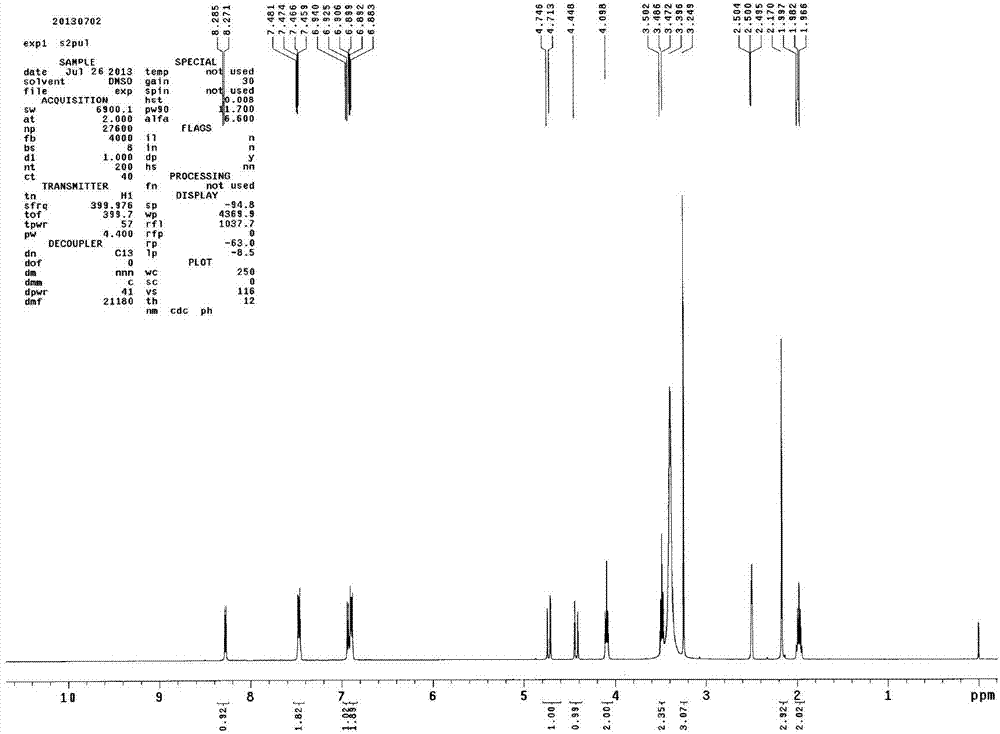

Image

Examples

Embodiment 1

[0022] Add 20 g of rabeprazole sulfide (molecular weight 266.1642) into a 1000 ml four-neck flask, add 400 g of toluene, heat up to 60°C and stir until it dissolves, add 16.8 g of L-(+)-diethyl tartrate (molecular weight 206.19), Tetraisopropyl titanate (molecular weight: 284.22) 11.6g, stir for 1 hour, add water 1g, keep stirring for 1 hour, add N,N-diisopropylethylamine (molecular weight: 129.25) 5.26g, react for 30 minutes, then cool down To 0°C, add 11 g of toluene solution of cumene hydroperoxide (molecular weight 152.19) dropwise, and keep the reaction for 12 hours after dropping, and monitor the progress of the reaction by TLC until the reaction is almost complete (developing agent: methanol-dichloromethane=1:10, ).

[0023] After the reaction, 200 ml of 10% NaOH aqueous solution was added, stirred for 30 minutes, and separated. The aqueous phase obtained after liquid separation, i.e. NaOH aqueous solution, was extracted (washed) once with 40 g of toluene, separated, a...

Embodiment 2

[0029]Add 20g of rabeprazole sulfide into a 1000ml four-necked flask, add 400g of toluene, raise the temperature to 60°C and stir until it dissolves, add 16.8g of L-(+)-diethyl tartrate, 11.6g of tetraisopropyl titanate After stirring for 1 hour, add 1 g of water, keep stirring for 1 hour, add 5.26 g of diisopropylethylamine, react for 30 minutes and cool down to 0 ° C, add dropwise a toluene solution of cumene hydroperoxide 11 g, and keep warm after dropping The reaction was carried out for 12 hours, and the progress of the reaction was monitored by TLC until the reaction was almost complete (developing solvent: methanol-dichloromethane=1:10).

[0030] After the reaction, 200 ml of 10% NaOH aqueous solution was added, stirred for 30 minutes, and separated. The aqueous phase obtained after liquid separation, i.e. NaOH aqueous solution, was extracted once with 40 g of toluene, and the liquid was separated, and then 80 g of toluene was added to the obtained water phase, the temp...

Embodiment 3

[0032] Add 20g of rabeprazole sulfide into a 1000ml four-necked flask, add 400g of toluene, raise the temperature to 60°C and stir until it dissolves, add 16.8g of L-(+)-diethyl tartrate, 11.6g of tetraisopropyl titanate , keep stirring for 2 hours, add 5.26g of diisopropylethylamine, react for 30 minutes and cool down to 0°C, add dropwise a toluene solution of 11g of cumene hydroperoxide, after dropping the heat preservation reaction for 72 hours, TLC monitors the reaction It shows progress until the reaction is not complete (developing solvent: methanol-dichloromethane=1:10).

[0033] Add 200 ml of 10% NaOH aqueous solution to the above reaction product, stir for 30 minutes, and separate the layers. The water phase obtained after liquid separation, that is, the NaOH aqueous solution was extracted once with 40 g of toluene, and the liquid was separated, and then 80 g of toluene was added to the obtained water phase, the temperature was lowered to about 5 ° C, and the pH was a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com