Sustained-release type elastic de-icing additive as well as preparation method and application thereof

A slow-release and additive technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of poor slow-release effect, high price, loss of ice and snow removal effect, etc., achieve long-term effective release effect and increase elasticity Shape-shifting capabilities, effects that are simple to apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The slow-release elastic deicing and snow additive of the present invention is prepared by the following method:

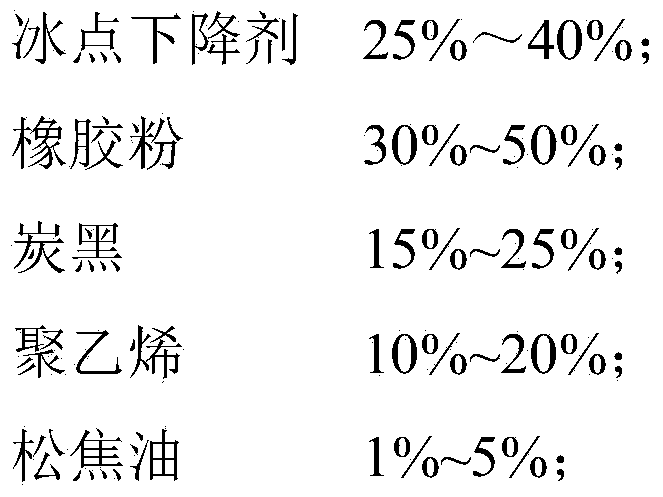

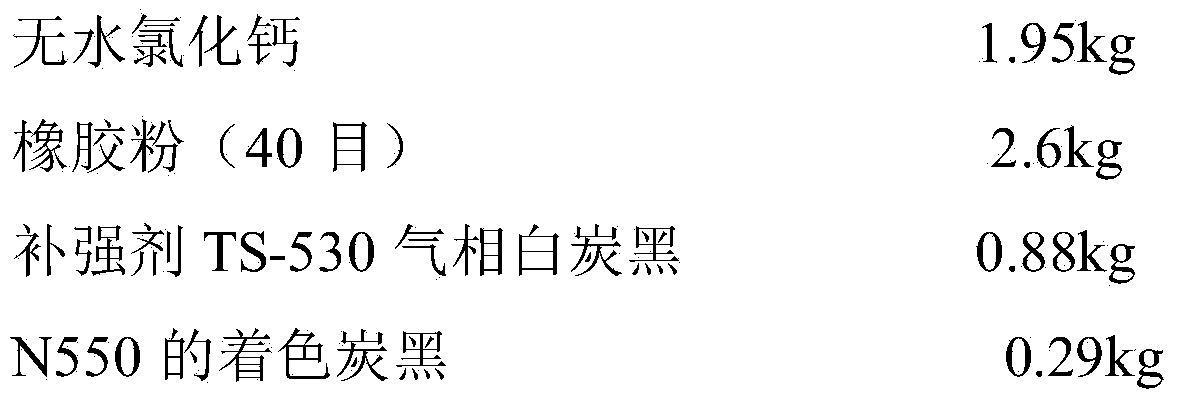

[0030] 1) First prepare component A, use industrial grade anhydrous calcium chloride, with a purity of ≥94%; the rubber powder is a 40-mesh rubber powder prepared by pulverizing the whole tire of an automobile bias tire at room temperature, and the waterproof film-forming material is epoxy resin ; polyethylene as reinforcing agent; carbon black is a mixture of colored carbon black of type N550 and reinforcing agent TS-530 fumed silica; this embodiment selects dark brown viscous pine tar liquid, and the corrosion inhibitor selects SiO 2 Quartz sand. The above materials are weighed according to the following weights:

[0031]

[0032]

[0033] Start the twin-screw extruder for preheating, set the torque to 70Nm, the temperature of the inlet to 180°C, and the temperature of the outlet to 200°C. Fully mix the weighed anhydrous calcium chloride and rubbe...

Embodiment 2

[0041]1) First prepare component A, use the mixture of analytically pure anhydrous sodium chloride and calcium chloride with a purity of ≥95% as the freezing point depressant, and the mass ratio of the two is 2:1; 80 mesh rubber powder is crushed, and epoxy resin is used as waterproof film-forming material; polyethylene particles are used as reinforcing agent; carbon black is a mixture of reinforcing agent TS-530 fumed silica and N550 colored carbon black; this example uses dark brown Viscous pine tar liquid, sodium hydroxide powder is selected as the corrosion inhibitor material. The above materials are weighed according to the following weights:

[0042]

[0043] Start the twin-screw extruder for preheating, set the torque to 70Nm, the temperature of the inlet to 180°C, and the temperature of the outlet to 200°C. Fully mix the weighed anhydrous calcium chloride and anhydrous sodium chloride evenly, add to the feeding hopper of the twin-screw extruder, weigh the rubber po...

Embodiment 3

[0051] 1) First prepare component A, use analytically pure anhydrous calcium chloride, with a purity of ≥95%; the rubber powder is 40-mesh rubber powder pulverized by the whole tire of an automobile radial tire at room temperature, and the waterproof film-forming material is selected from tung oil; polyethylene particles are used as reinforcing agent ; Carbon black is the mixture of coloring carbon black of type N550 and reinforcing agent TS-530 fumed silica; this embodiment selects dark brown viscous pine tar liquid, and selects sodium nitrite powder as corrosion inhibitor. The above materials are weighed according to the following weights:

[0052]

[0053] Start the twin-screw extruder for preheating, set the torque to 70Nm, the inlet temperature to 180°C, and the outlet temperature to 200°C. Fully mix the weighed anhydrous calcium chloride and rubber powder evenly, add it to the feeding hopper of the twin-screw extruder, weigh the carbon black and polyethylene particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com