Thermal oxidation stabilizing additive for polyamide

A technology for stabilizing additives and polyamides, used in organic chemistry, chemical instruments and methods, preparation of organic compounds, etc. Improve anti-yellowing effect

Inactive Publication Date: 2015-02-04

SUZHOU UNIV +2

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the presence of polyols may cause a sharp increase in the melt viscosity of polyamide and destroy its thermoplastic molding processability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0033] Example 1: 100 parts by weight of polyamide 6 + 5 parts by weight of lanthanum pyromellitic acid compound.

Embodiment 2

[0034] Example 2: 100 parts by weight of polyamide 6 + 5 parts by weight of gadolinium pyromellitic acid compound.

Embodiment 3

[0035] Example 3: 100 parts by weight of polyamide 6 + 5 parts by weight of scandium pyromellitic acid compound.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

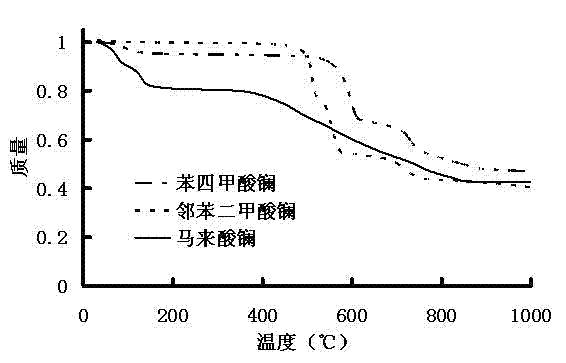

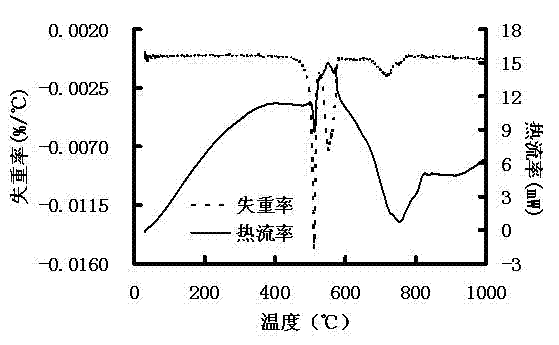

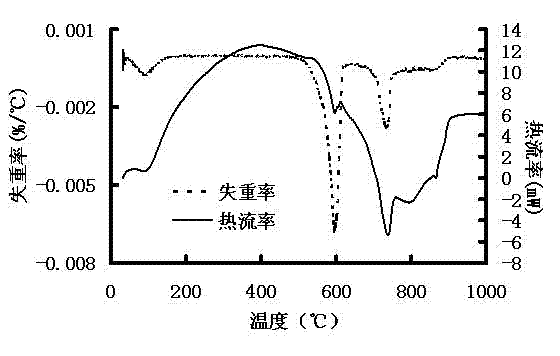

The invention discloses a thermal oxidation stabilizing additive for polyamide. The additive is a rare earth metal organic acid salt, and the rare earth metal organic acid salt is prepared through the following steps: 1, carrying out a reaction on equivalent amounts of an organic acid or organic acid anhydride solution and an aqueous solution of an inorganic alkali according to a chemical reaction equation to generate an organic acid salt solution; 2, carrying out a reaction on equivalent amounts of the organic acid solution and rare earth metal ions according to a chemical reaction equation to generate a rare earth metal organic acid salt solution; and 3, carrying out pumping filtration on the rare earth metal organic acid salt solution prepared in step 2, washing with water, drying, and grinding to obtain the rare earth metal organic acid salt. The additive can effectively improve the yellowing resistance, that is, thermo-oxidative stability, of polyamide, and can be widely applied in the thermoplastic molding processing process of polyamide.

Description

technical field [0001] The invention relates to an additive, in particular to a thermo-oxidative stabilizing additive for polyamide, and belongs to the field of polymer molding processing aids. Background technique [0002] Polyamide, especially polyamide 66 with a high melting point, is prone to thermo-oxidative degradation during thermoplastic molding and spinning. During the thermal oxidation process of polyamide, macromolecular chain scission and crosslinking will occur, which will lead to the deterioration of the mechanical properties of polyamide. The thermal degradation reaction of polyamide mainly includes three types: (1) The thermal degradation reaction of polyamide follows a typical chain reaction process: the main degradation product can preferentially attack the hydrogen atom on the methylene group connected to the nitrogen atom through free radicals. (2) Free radical degradation of polyamide macromolecular chains, especially all methylene groups. (3) The clea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/00C08K5/098C07C51/41C07C63/313C07C63/20C07C63/307C07C57/145

CPCC08K5/098C07C51/418C08L2201/08C08L77/02C08L77/06C07C57/145C07C63/20C07C63/307C07C63/313

Inventor 朱新生周正华龚剑兵艾丽万宇辉黄然

Owner SUZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com