Control circuit of power MOSFET switching tube source electrode drive topological structure

A MOS tube and source drive technology is applied to the control circuit field of the power MOSFET switch tube source drive topology, which can solve the problems of unfavorable LED drive circuit design, high cost, and high loss of the drive circuit, and achieves a simple and reliable control method. Reduce volume and cost, optimize the effect of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

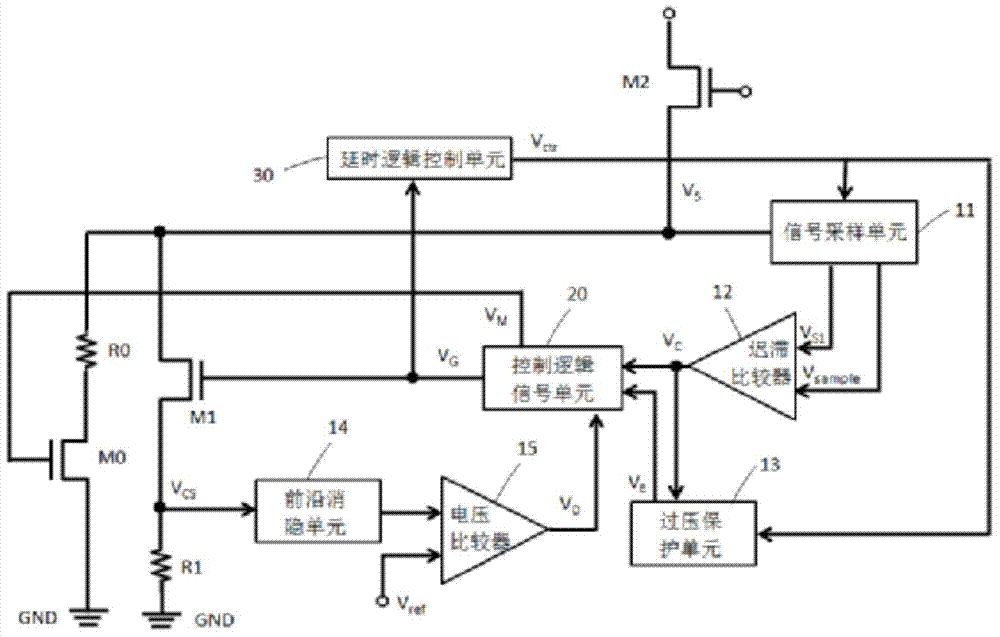

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

[0024] like image 3 As shown, a control circuit of a power MOSFET switch tube source drive topology proposed by the present invention includes a power MOSFE switch tube M2, a high-voltage switch MOS tube M1, a resistor R1, a delay logic control unit (30), and a signal sampling A unit (11), a hysteresis comparator (12), an overvoltage protection unit (13), a leading edge blanking unit (14), a voltage comparator (15) and a control logic signal unit (20).

[0025] The source of the power MOSFET switch M2 is connected to the drain of the high-voltage switch MOS transistor M1, and the gate and drain of the power MOSFET switch M2 are respectively connected to an external power supply voltage and a transformer or an inductor.

[0026] The source of the high-voltage switch MOS transistor M1 is connected to the circuit ground G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com