Aluminum alloy water-based mold release agent and preparation method thereof

A release agent, aluminum alloy technology, applied in the field of aluminum alloy manufacturing, can solve the problems of casting surface influence, high cost, easy to produce oil pollution, etc.

Inactive Publication Date: 2015-02-11

TIANJIN GAOBO ALUMINUM

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned aluminum alloy die-casting needs to be demolded after production. In order to ensure that the casting is easy to take out, a release agent must be applied to the inner edge of the metal mold. Water-based release agents are more commonly used, but the existing formulations are more random, and the surface of the casting will be somewhat affected

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

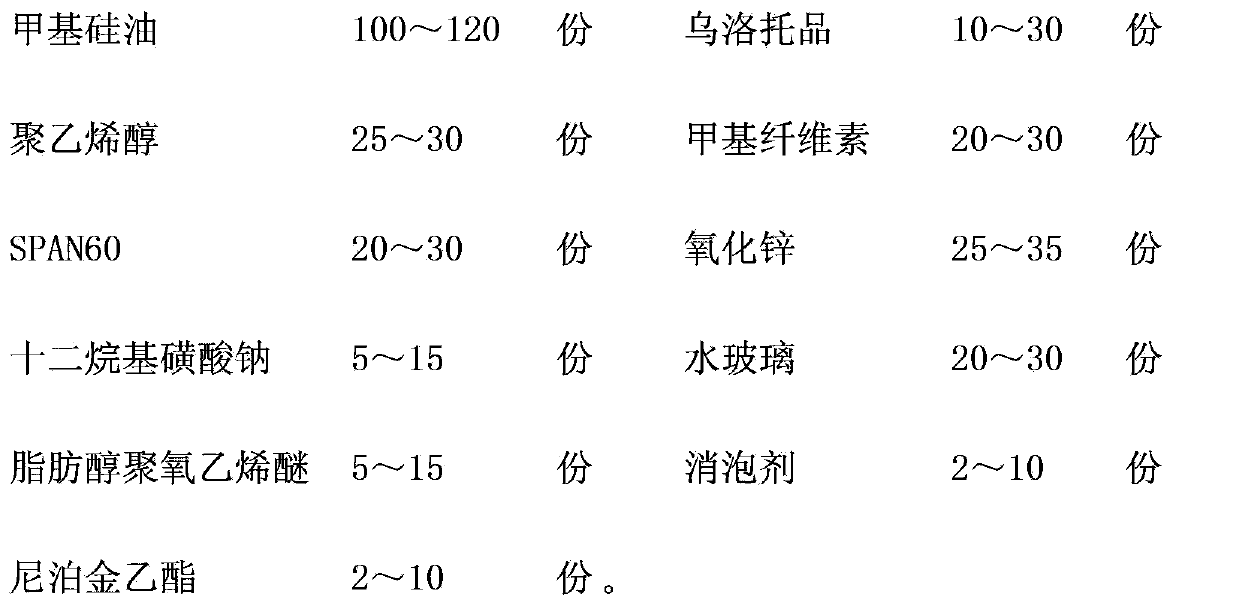

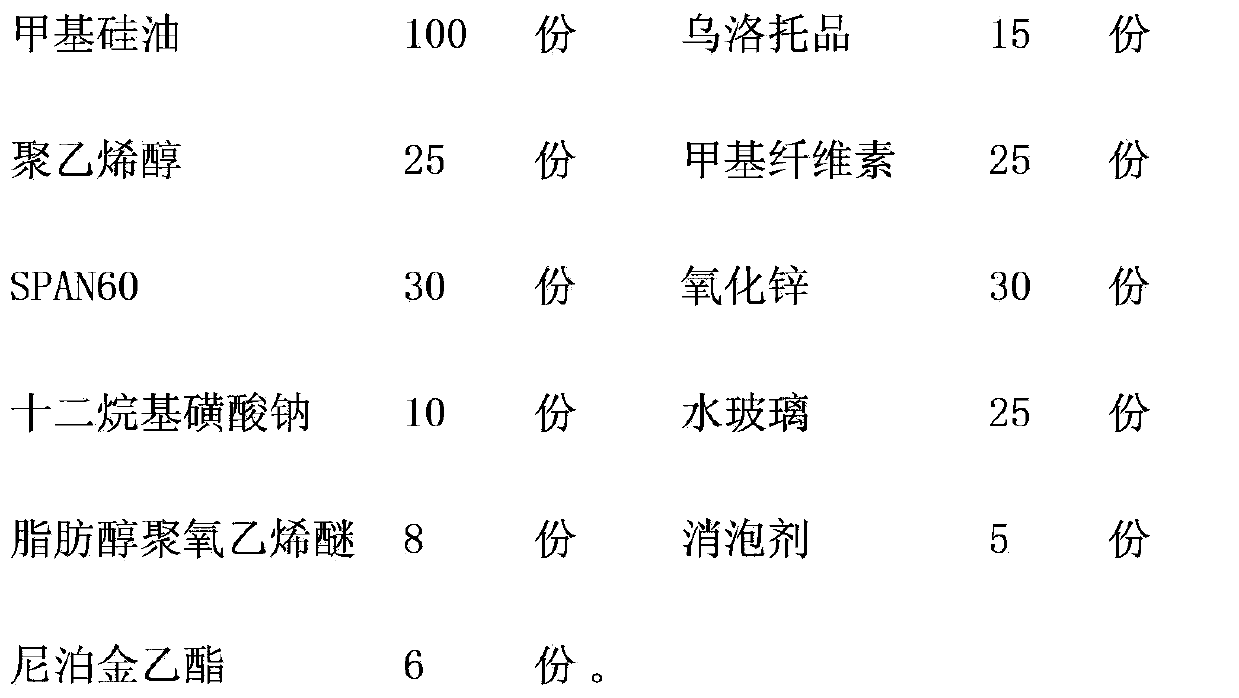

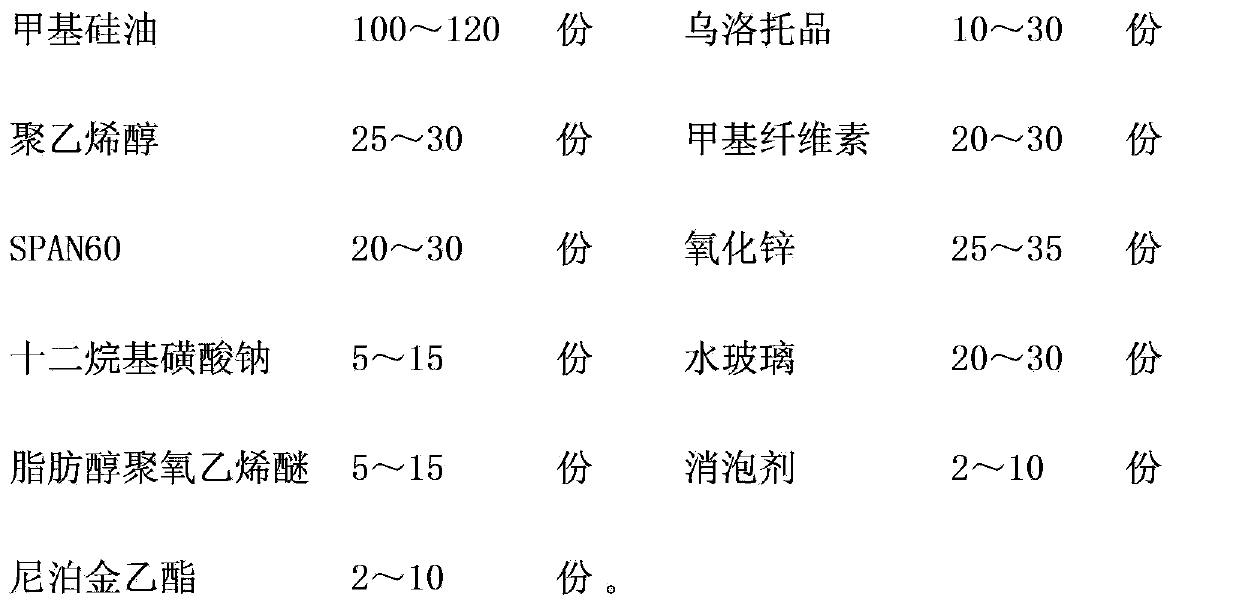

The invention relates to an aluminum alloy water-based mold release agent. Raw materials of the aluminum alloy water-based mold release agent comprise methylsilicone oil, polyvinyl alcohol, SPAN60, sodium dodecyl sulfate, fatty alcohol-polyoxyethylene ether, ethylparaben, urotropin, methylcellulose, zinc oxide, water glass and antifoaming agent. All the components are weighed by measurements, and are evenly mixed; then, water of 15 times of the weight is added for evenly mixing to obtain the finished product; the mold release agent can be coated, brushed and dipped on the inner edge surface of a metal mold by a spray gun, is excellent in high-temperature lubrication performance, has no need to frequently overhaul the mold, can prolong the service life of the metal mold, and saves the labor hour; and a die casting is smooth and bright in surface, and is clear in outline.

Description

technical field The invention belongs to the technical field of aluminum alloy manufacturing, in particular to an aluminum alloy water-based release agent and a preparation method thereof. Background technique Aluminum alloy is a general term for alloys based on aluminum. The other metal elements involved mainly include copper, silicon, magnesium, zinc and manganese, and mainly nickel, iron, titanium, chromium and lithium. The density of aluminum alloy is low, but its strength is relatively high, which is close to or exceeds that of high-quality steel. It has good plasticity and can be processed into various profiles. It has excellent electrical conductivity, thermal conductivity and corrosion resistance, and has been widely used in industry. Its consumption is second only to steel. In the production process of aluminum alloy castings, die casting is a precision casting method that uses high pressure to press aluminum alloy melt into a metal mold with complex shape and coo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22C3/00B22D17/22

CPCB22C3/00B22D17/22

Inventor 高学伶

Owner TIANJIN GAOBO ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com