A kind of rapid repair material for various road types and its construction application method

A technology for repairing materials and road types, which is applied in the field of rapid repairing materials to achieve the effects of excellent mechanical properties, simple construction and solving the problem of road congestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

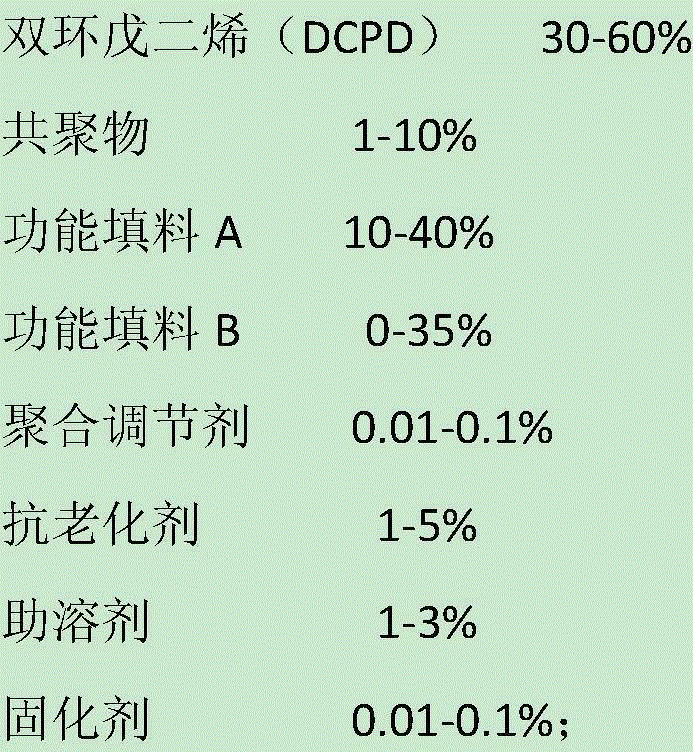

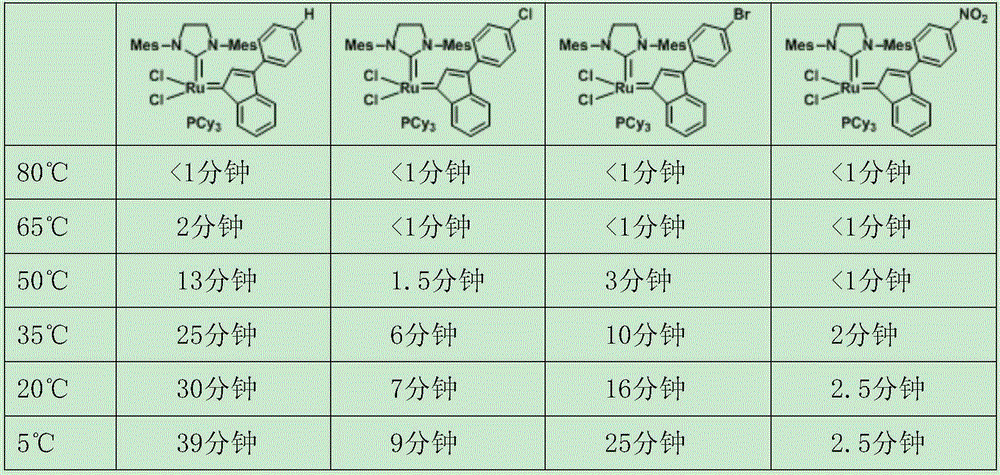

[0044] The quick patching material for multiple road types of the present invention is applied to cement concrete type roads and comprises the following components by weight: 53.98% dicyclopentadiene, 3% styrene, 40% silicon dioxide, triphenyl Phosphine 0.01%, p-tert-butylphenol 1%, toluene 2%, curing agent 0.01%.

[0045] The construction and use method of the above-mentioned road rapid repair materials, after the road surface is cleaned, proceed according to the following steps:

[0046] 1. Fully mix dicyclopentadiene, styrene, silicon dioxide, triphenylphosphine, p-tert-butylphenol and 1 / 2 weight of toluene to obtain slurry A;

[0047] 2. Add the curing agent Dissolved in the remaining toluene to obtain a transparent solution B;

[0048] 3. After fully mixing A and B, fill in the parts to be repaired. Cover it with a smooth glass plate.

[0049] 4. Outdoor at 20 degrees, solidify after 7 minutes, and lift the glass plate. After about 30 minutes, smooth the repaired ...

Embodiment 2

[0051]The quick patching material for multiple road types of the present invention is applied to asphalt expressways, and comprises the following components by weight ratio: 46% dicyclopentadiene, 1% butadiene, 15.89% wollastonite, asphalt 35%, diethylene glycol dibutyl ether 0.1%, tert-butyl hydroquinone 1%, dichloromethane 1%, curing agent 0.01%.

[0052] The construction and use method of the above-mentioned road rapid repair materials, after the road surface is cleaned, proceed according to the following steps:

[0053] 1. Fully mix dicyclopentadiene, butadiene, wollastonite, diethylene glycol dibutyl ether, tert-butyl hydroquinone and 2 / 3 weight of dichloromethane to obtain slurry A;

[0054] 2. Add the curing agent Dissolved in the remaining dichloromethane to obtain a transparent solution B;

[0055] 3. After fully mixing A and B, fill in the parts to be repaired. Cover it with a smooth glass plate.

[0056] 4. Outdoor at 35 degrees, solidified after 30 minutes, ...

Embodiment 3

[0058] The quick patching material for multiple road types of the present invention is applied to cement concrete roads and comprises the following components by weight ratio: 60% dicyclopentadiene, 10% butyl methacrylate, 1% glass fiber, poly Styrene 22.8%, 2,6-di-tert-butyl-p-cresol 0.1%, aniline 3%, tetrahydrofuran 3%, curing agent 0.1%.

[0059] The construction and use method of the above-mentioned road rapid repair materials, after the road surface is cleaned, proceed according to the following steps:

[0060] 1. Fully mix dicyclopentadiene, butyl methacrylate, glass fiber, 2,6-di-tert-butyl-p-cresol, aniline and 3 / 5 weight tetrahydrofuran to obtain slurry A;

[0061] 2. Add the curing agent Dissolved in the remaining tetrahydrofuran to obtain a transparent solution B;

[0062] 3. After fully mixing A and B, fill in the parts to be repaired. Cover it with a smooth glass plate.

[0063] 4. Outdoor at 10 degrees, solidified after 25 minutes, and opened the glass pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com