Confined vortex flow reactor and application thereof to preparation process of Me-SAPO-34 molecular sieve

A reactor and confinement technology, which is applied in the field of chemical reaction preparation technology, can solve the problems of limiting the catalytic performance of materials, the particle size of molecular sieves and the influence of uniform dispersion performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

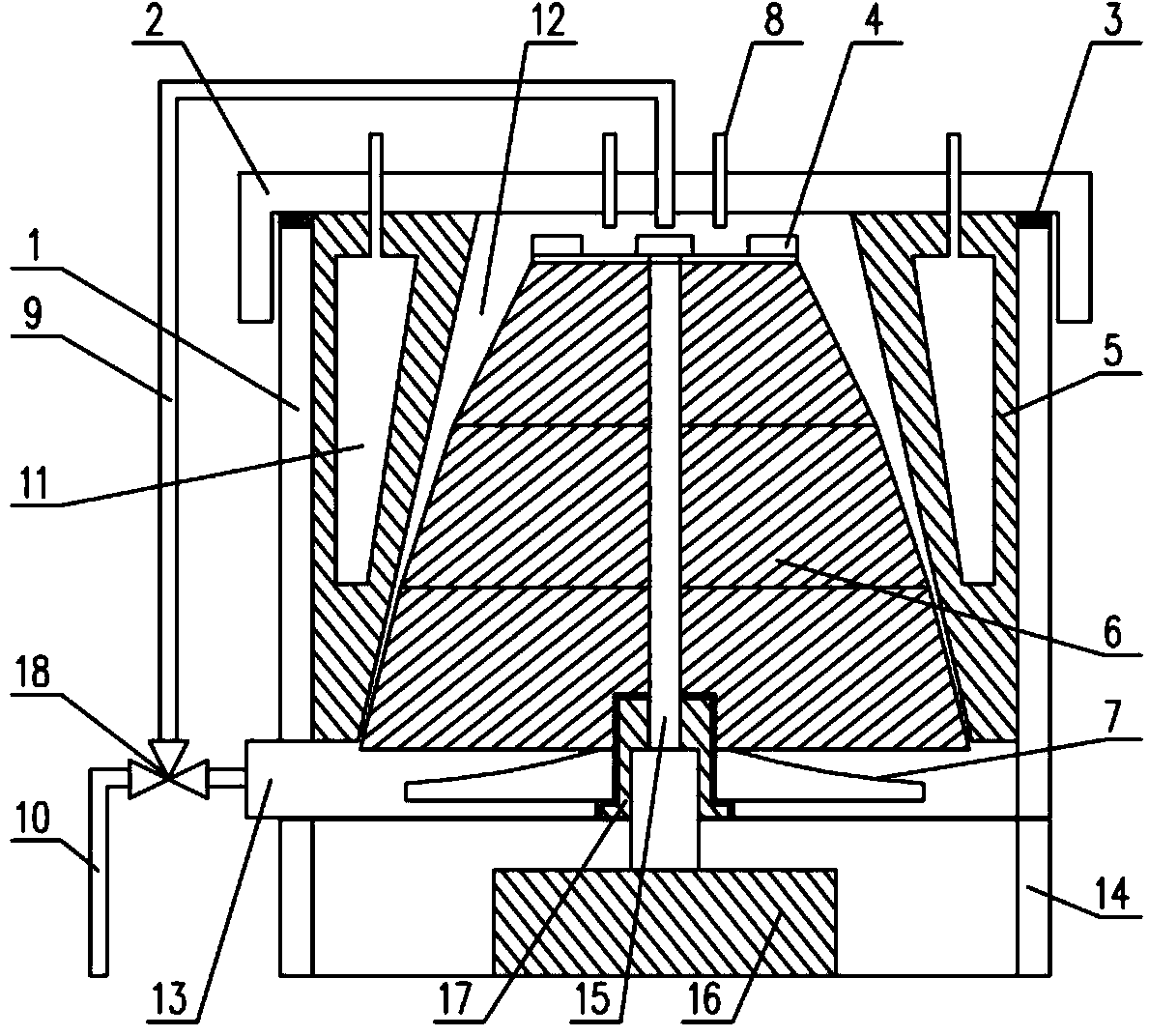

[0051] Such as figure 1It is a schematic diagram of a preferred embodiment of the confinement cyclone reactor created by the present invention, including a casing (1), internal teeth (6) and external teeth (5), the casing (1) is fixed on the base (14), and the The internal teeth (6) are fixed on the rotating shaft (15), the external teeth (5) are arranged on the periphery of the internal teeth (6), and the external teeth (5) are fixed on the bottom surface of the cover (2), so that The outer teeth (5) are close to the inner wall of the casing (1), the inner teeth (6) and the outer teeth (5) form a multi-stage reaction channel (12), and a liquid distributor (4) is fixed above the inner teeth (6) ), the liquid distributor (4) top corresponds to the liquid outlet of the feed delivery pipe (8) of the feed device, and the bottom of the multi-stage reaction channel (12) communicates with the discharge channel (13), and the rotating shaft ( 15) Pass through the discharge passage (13...

Embodiment 2

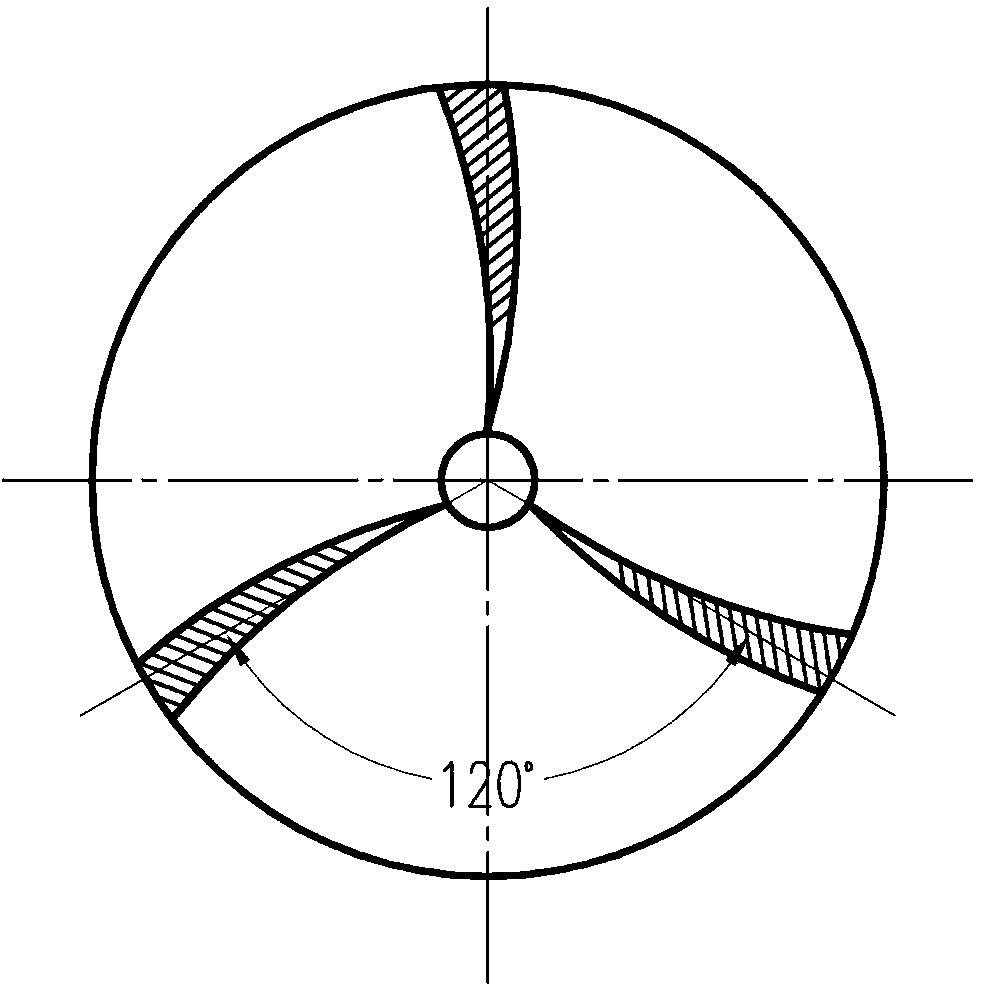

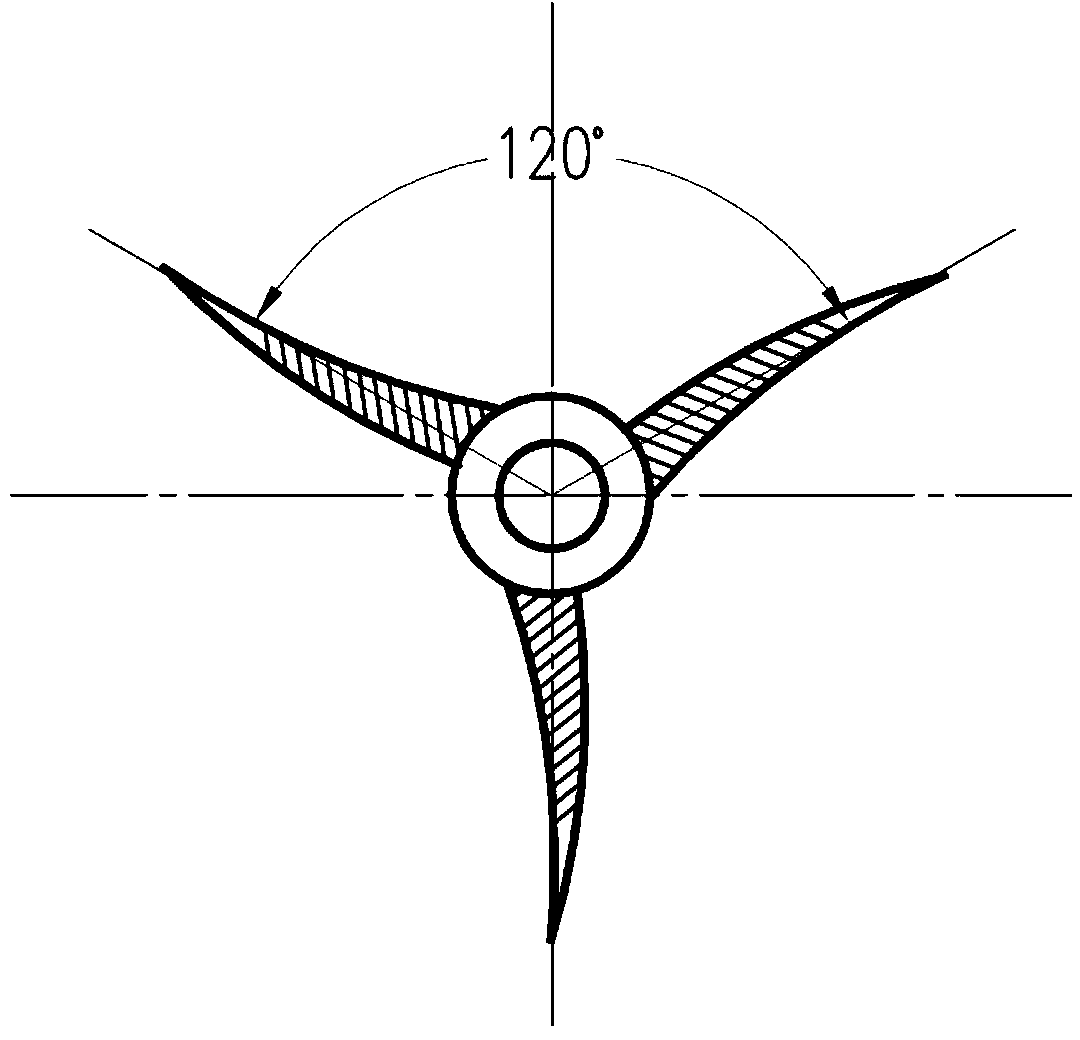

[0056] Such as Figure 5 It is a schematic diagram of a preferred embodiment of the confinement cyclone reactor created by the present invention. The difference from Example 1 is that the liquid distributor (4), such as Figure 6 Shown, be the disk that has 3 blade-type protrusions, and described blade-type protrusion is a triangular prism; In the discharge channel (13) below is as Figure 7 The discharge rotary impeller (7) shown has 3 gradually closed arc-shaped blades, which are semi-open; the cone angles of the upper, middle, and lower stages are 70°, 80°, and 82° successively, and the upper stage The diameter of the bottom surface of the circular platform is 2mm smaller than the diameter of the top surface of the intermediate circular platform, and the area of the bottom surface of the intermediate circular platform is equal to the area of the top surface of the lower circular platform. The space angle is 85°; corresponding to the three-stage circular frustum of the ...

Embodiment 3

[0060] The CoNi-SAPO-34 molecular sieve that adopts the confinement cyclone reactor of embodiment 1 to prepare bimetallic modification, its concrete steps are:

[0061] Water glass and phosphoric acid are formulated into a mixed aqueous solution A with a molar ratio of 3, wherein [SiO 2 ]=2.0mol / L; Pseudoboehmite, cobalt nitrate, nickel nitrate and tetraethylammonium hydroxide are made into the mixed aqueous solution B that molar ratio is 2:1:1:5, wherein [Co 2+ ]=[Ni 2+ ]=0.4mol / L; Two solutions A and B are added to the reactor for mixed reaction through two feed delivery pipes (8) above the reactor respectively; the multistage reaction channel (12) width range is adjusted to be 50-320 μm , the rotating speed of inner tooth (6) is 7000 rpm, and the flow rate of the mixed liquid in the discharge conveying pipe (10) is 1400kg / h. After aging the obtained mixture at room temperature for 3 hours, it was grown under autogenous pressure hydrothermal conditions at 180°C for 60 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com