Ceramic composite with high absorptive property and preparation method of ceramic composite

A ceramic composition and high adsorption technology, applied in the field of composite ceramic materials, can solve problems such as narrowing the application field, and achieve the effects of high flexural strength, low firing shrinkage rate and strong adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

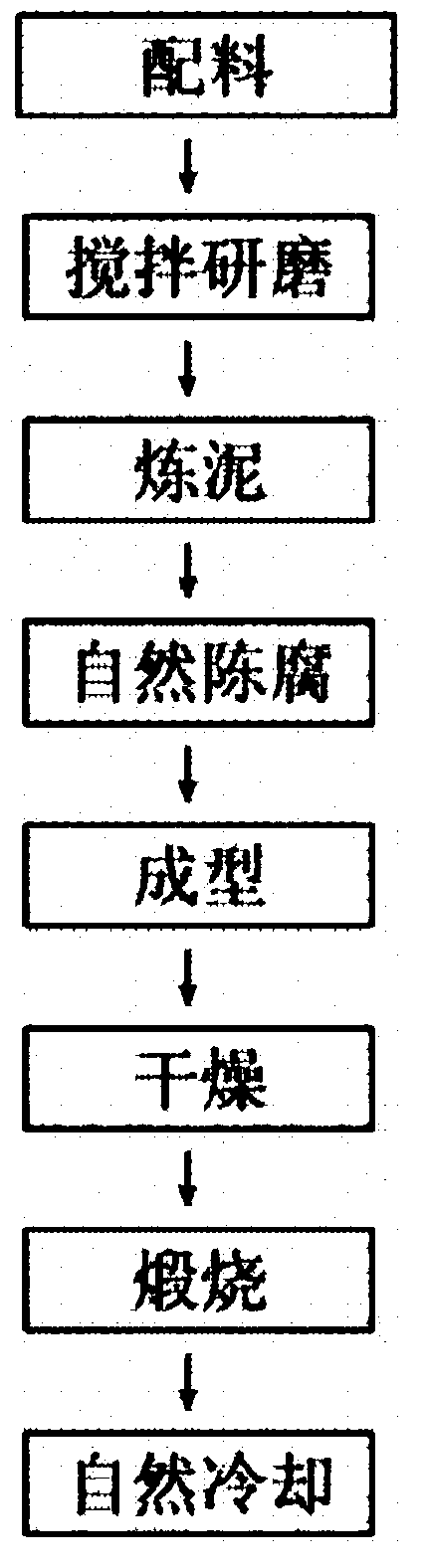

Method used

Image

Examples

Embodiment 1

[0035] Raw materials are configured by weight percentage: 9.3% of crystallized bamboo charcoal powder, 0.2% of graphene, 0.5% of titanium dioxide, 50% of tourmaline crystal particles, and 40% of clay. The crystallized bamboo charcoal powder used in this embodiment is fired at a high temperature above 1200° C., and the average particle size of the bamboo charcoal powder is 30 μm to 100 μm. The tourmaline powder used is high-purity tourmaline ore crystal, tourmaline crystallinity ≥ 95%, dynamic negative ion value ≥ 500ions / cm3, far-infrared radiation rate ≥ 90% with a wavelength of 4 μm to 14 μm. The average particle size of the tourmaline powder is 10 μm to 50 μm. After mixing, forming, drying, and slowly heating up to 600-800°C in a reducing atmosphere for calcination, pottery casserole and electric rice cooker liner are produced.

Embodiment 2

[0037] Raw materials are configured by weight percentage: 74% of crystallized bamboo charcoal powder, 0.5% of graphene, 5% of titanium dioxide, 10% of tourmaline crystal particles, and 10.5% of clay. The crystallized bamboo charcoal powder used in this embodiment is fired at a high temperature above 1200° C., and the average particle size of the bamboo charcoal powder is 30 μm to 100 μm. The tourmaline powder used is high-purity tourmaline ore crystal, tourmaline crystallinity ≥ 95%, dynamic negative ion value ≥ 500ions / cm3, far-infrared radiation rate ≥ 90% with a wavelength of 4 μm to 14 μm. The average particle size of the tourmaline powder is 10 μm to 50 μm. After mixing, molding, drying, and slowly heating up to 600-800°C in a reducing atmosphere for calcination, ceramic tea sets and tableware are produced.

Embodiment 3

[0039]Raw materials are configured by weight percentage: 25% of crystallized bamboo charcoal powder, 0.3% of graphene, 3% of titanium dioxide, 31.7% of tourmaline crystal particles, and 40% of clay. The crystallized bamboo charcoal powder used in this embodiment is fired at a high temperature above 1200° C., and the average particle size of the bamboo charcoal powder is 30 μm to 100 μm. The tourmaline powder used is high-purity tourmaline ore crystal, tourmaline crystallinity ≥ 95%, dynamic negative ion value ≥ 500ions / cm3, far-infrared radiation rate ≥ 90% with a wavelength of 4 μm to 14 μm. The average particle size of the tourmaline powder is 10 μm to 50 μm. After mixing, forming, drying, and slowly heating up to 600-800°C in a reducing atmosphere for calcination, a food preservation container is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com