High-strength semitransparent ceramic material and preparation method of ceramic sheet

A ceramic material and semi-permeable technology, applied in the field of architectural ceramics, can solve the problems of many damages and high maintenance costs, and achieve the effects of improving strength and toughness, solving brittleness problems and multi-decorative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

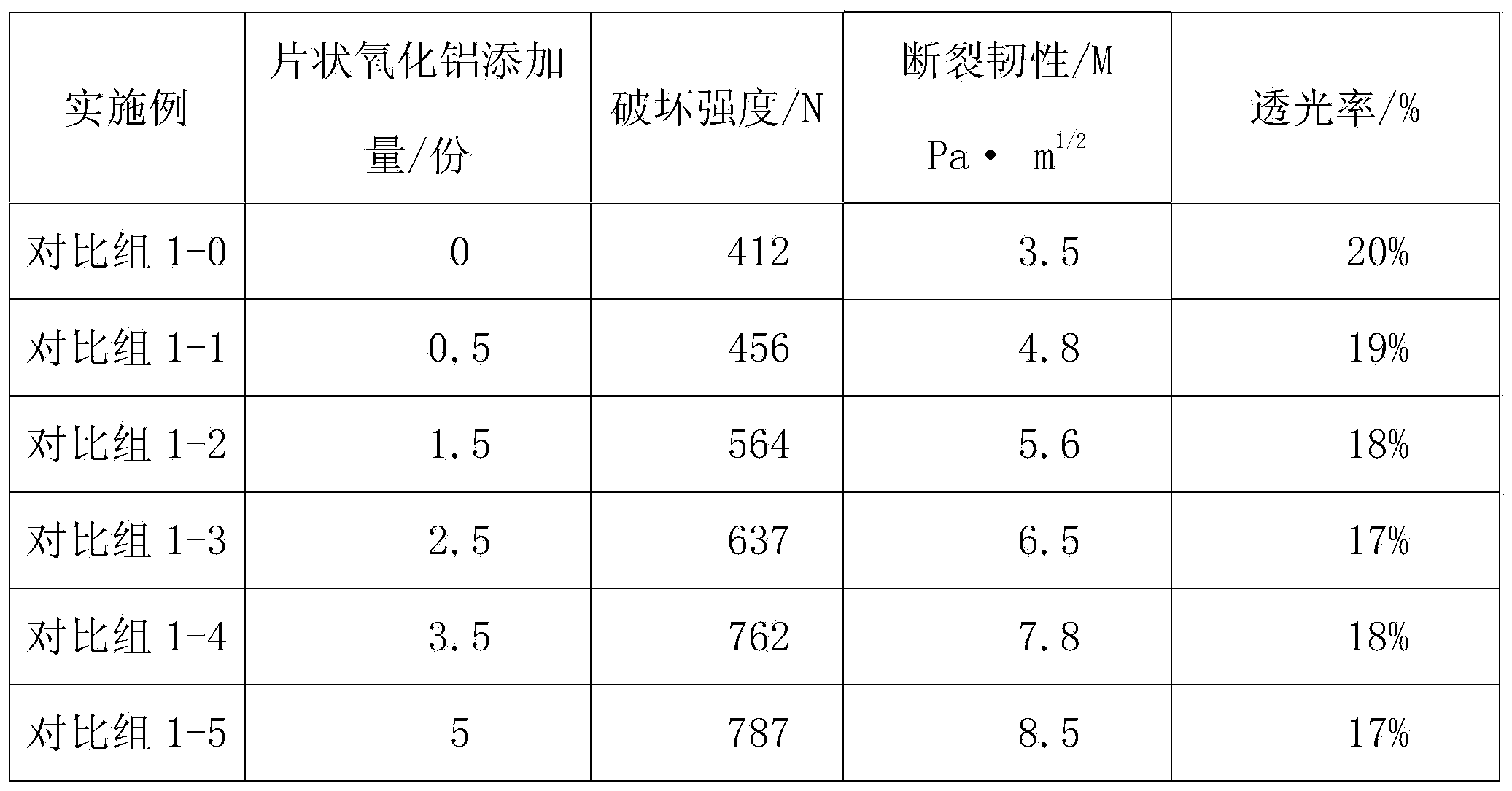

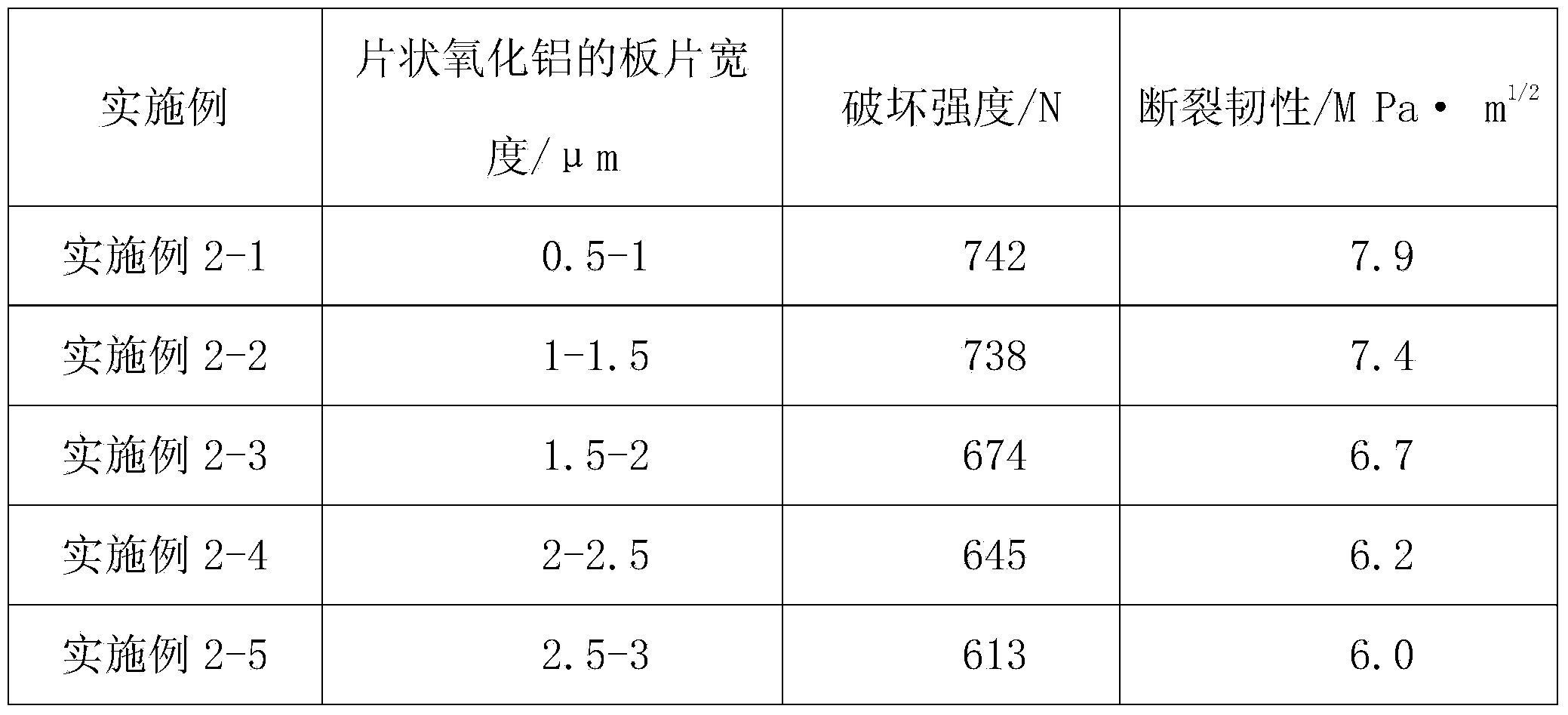

[0021] A. Preparation of powder: mix the raw materials according to the following proportions by mass: 30 parts of sodium sand, 25 parts of potassium feldspar, 10 parts of high potassium sand, 5 parts of potassium sodium feldspar, 3 parts of barium carbonate, and 5 parts of ball soil 10 parts, 10 parts of bone meal, using wet ball milling, the slurry is spray-dried to obtain the base material powder; 2 parts of aluminum borate whiskers and flaky aluminum oxide (added in the amount shown in Table 1, plate The width is 0.5-0.8 μm) and the base material powder prepared above are mixed, and stirred and mixed evenly to obtain the powder;

[0022] B. Put the powder in the mould, press to form, and dry; the size of the mold selected in this embodiment is 2300mm×1150mm, and the thickness of the green body is controlled by controlling the amount of powder distribution, and the size of the prepared brick is 2200×1100mm ×66mm;

[0023] C. Send it to a kiln for firing at a firing tempera...

Embodiment 4

[0047] A method for preparing a high-strength semipermeable ceramic sheet is as follows:

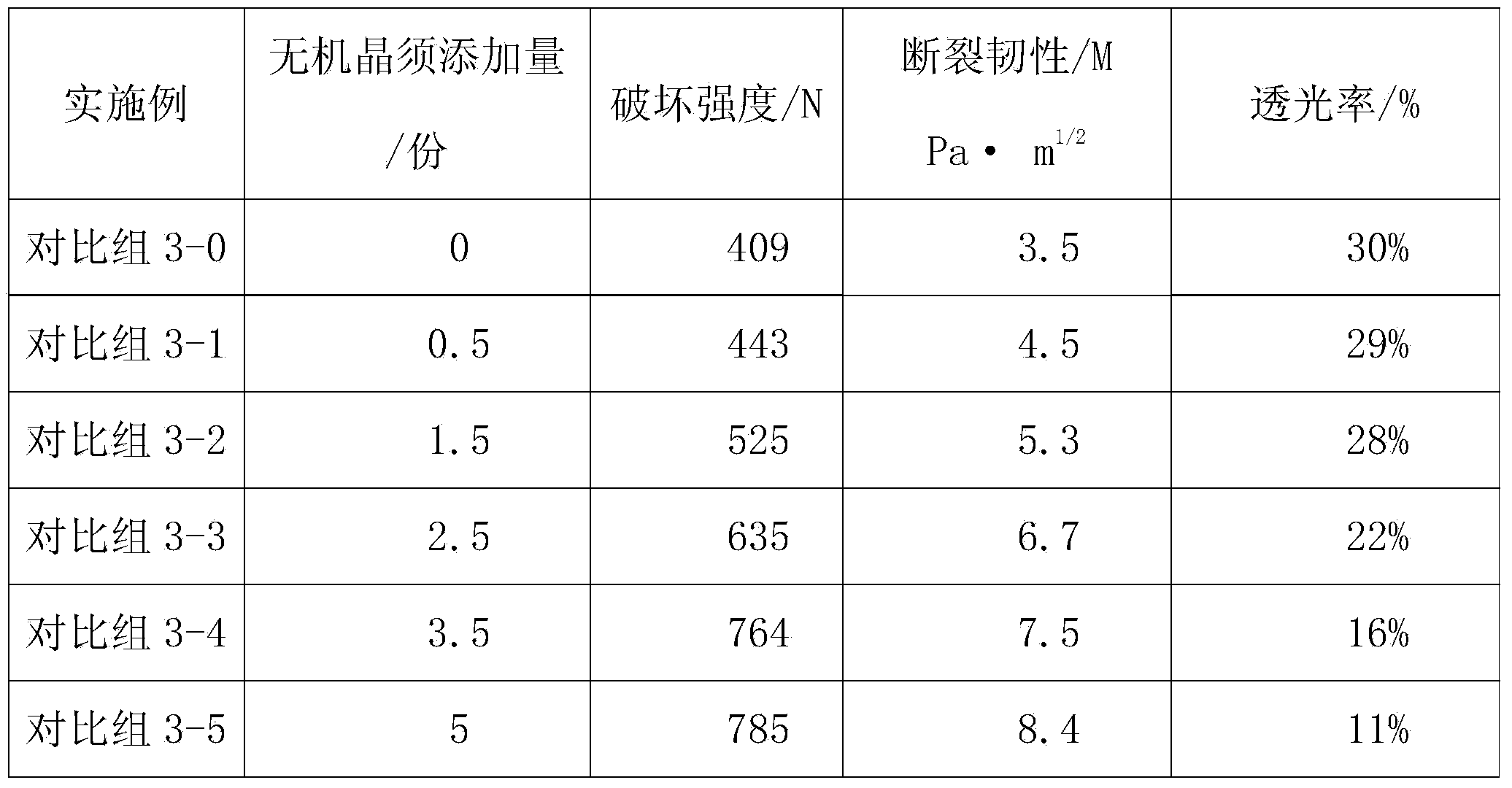

[0048] A. Preparation of powder: mix the raw materials according to the following proportions by mass: 35 parts of sodium sand, 15 parts of potassium feldspar, 8 parts of high potassium sand, 10 parts of potassium sodium feldspar, 4 parts of barium carbonate, and 9 parts of ball soil Parts, 15 parts of bone meal, using wet ball milling, the slurry is spray-dried to obtain the base material powder; , 1 part of aluminum borate whiskers is mixed with the base material powder prepared above, and stirred and mixed evenly to obtain the powder;

[0049] B, the powder cloth is placed in the mould, pressed and molded, and dried; the used mold and the amount of cloth are the same as the series of embodiment 1.

[0050] C. Send it to a kiln for firing. The firing temperature is 1250°C, the firing cycle is 80 minutes, and the edges are polished and edging to obtain a high-strength semi-permeable ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com