Bamboo-plastic fiber composite plate/rubber sheet laminated earthquake-isolation bearing and manufacturing method of earthquake-isolation bearing

A fiber composite board and vibration isolation bearing technology, which is applied in rubber layered products, chemical instruments and methods, synthetic resin layered products, etc. Problems such as low standards and large proportions are beneficial to long-distance transportation and installation, light weight and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

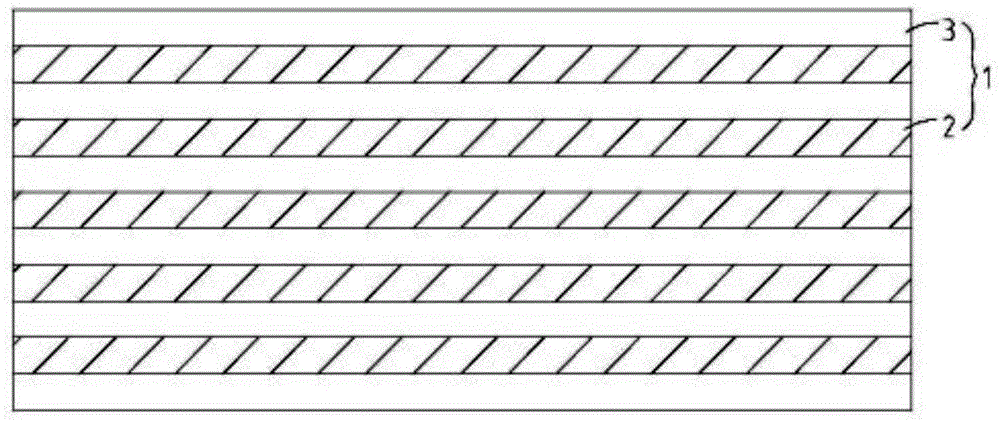

[0049] Such as figure 1 As shown, a bamboo-plastic fiber composite board / rubber sheet laminated shock-isolation bearing includes a bearing main body 1, and the bearing main body includes a rubber sheet 3 and a bamboo-plastic fiber composite board 2, and the rubber sheet 3 and bamboo The plastic fiber composite boards 2 are stacked alternately, the two outer layers of the support main body 1 are rubber sheets 3 , and the support main body 1 includes 1-10 layers of bamboo plastic fiber composite boards 2 . Preferably, the thickness of the bamboo-plastic fiber composite board 2 is 2-10 mm. Further preferably, the horizontal section of the bamboo-plastic fiber composite board 2 is rectangular or circular. In the present invention, the steel plate is replaced by the bamboo-plastic fiber composite board, and the dried rubber sheet and the bamboo-plastic fiber composite board are alternately stacked in the mould, and vulcanized to obtain a kind of shock-isolation structure that can ...

Embodiment 2

[0051] A method for manufacturing a bamboo-plastic fiber composite board / rubber sheet laminated shock-isolation bearing, comprising the following steps:

[0052] S1. Production of bamboo-plastic fiber composite board:

[0053] Bamboo powder with a particle size of 100 mesh was placed in a high-speed mixer, vacuum-dried at 110° C. for 1 hour, then cooled to 95° C. and vacuum-dried for 6 hours, and then used.

[0054] S101. Put 60 parts by mass of isotactic polypropylene, 45 parts by mass of bamboo powder, 10 parts by mass of alkali-free glass fiber precursors with a length of 4.5 mm, and 8 parts by mass of acicular wollastonite with a particle size of 30 μm into a high-speed mixer After dispersing at 300r / min for 2h, heat up to 115°C, then add 2 parts by mass of A-171 silane coupling agent and 4 parts by mass of maleic anhydride grafted polypropylene, and disperse at 300r / min for 8min Finally, put it into the cold mixing pot to cool, and discharge the material when the tempe...

Embodiment 3

[0073] A method for manufacturing a bamboo-plastic fiber composite board / rubber sheet laminated shock-isolation bearing, comprising the following steps:

[0074] S1. Production of bamboo-plastic fiber composite board:

[0075] Bamboo powder with a particle size of 60 mesh was placed in a high-speed mixer, vacuum-dried at 110° C. for 1 hour, then cooled to 95° C. and vacuum-dried for 6 hours, and then used.

[0076] S101, 40 mass parts of high-density polyethylene, 50 mass parts of bamboo powder, 5 mass parts of alkali-free glass fiber precursors with a length of 3 mm and 5 mass parts of light calcium carbonate with a particle diameter of 10 μm are packed into a high-speed mixer, After dispersing at 200r / min for 1 hour, raise the temperature to 110°C, add 1 mass part of A-151 silane coupling agent and 2 mass parts of maleic anhydride grafted polyethylene, disperse at 400r / min for 6 minutes, and put Cool in a cold mixing pot, and discharge when the temperature drops to 45°C t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com