Method for extracting and separating germanium by extraction and leaching resin

A technology for leaching resin and macroporous resin is applied in the field of separation and enrichment of germanium, which can solve the problems of serious environmental pollution, complicated germanium method and high cost, and achieve the effects of high purity, good separation and enrichment effect and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

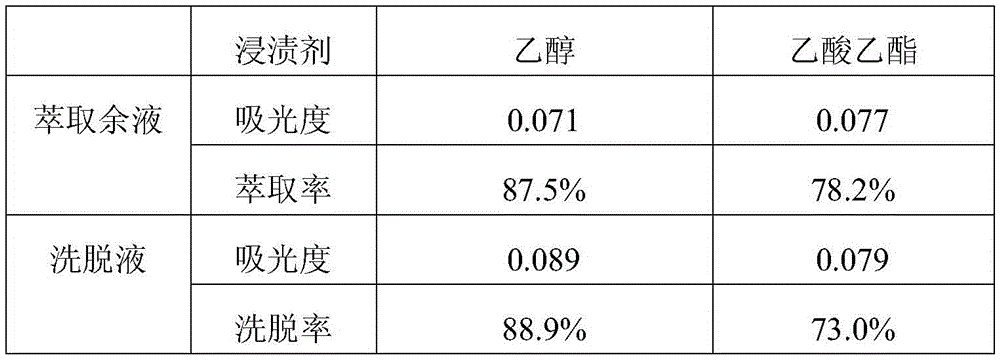

[0015] The selection of embodiment 1 impregnating agent

[0016] (1) Method

[0017] 1) Preparation of extraction resin: weigh AB-8 macroporous resin, wash with absolute ethanol or ethyl acetate. Take 50g of the cleaned AB-8 macroporous resin and 20g of N235 in a container, add 10mL of ethanol or ethyl acetate and mix well, stir in a water bath at 60°C for 2 hours, heat up to 80°C and evaporate the ethanol or ethyl acetate to dryness, respectively N235 extraction resin treated with different impregnating agents was prepared.

[0018] 2) Adsorption: take 30mL of germanium-containing solution with a concentration of 1mg / mL, add 0.1g of N235 extraction resin treated with different impregnating agents and 0.1g of tartaric acid, adjust the pH to about 2.0 with sulfuric acid, oscillate and stir for 90min, filter, and obtain adsorption N235 extraction resin and raffinate of germanium;

[0019] 3) Elution: Add 10 mL of NH with a concentration of 4 mol / L to the N235 extraction resin...

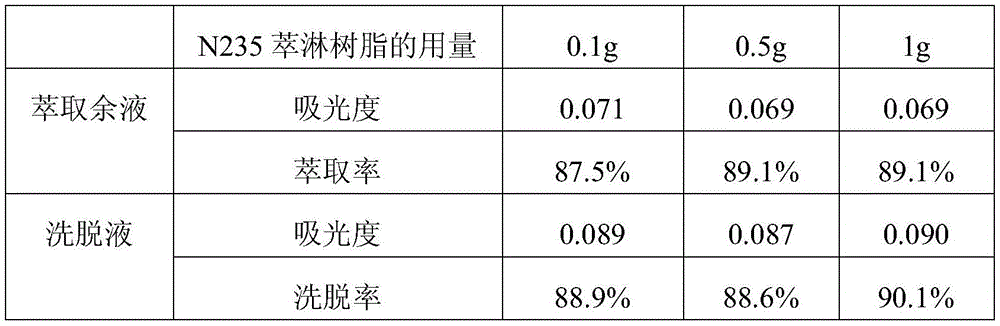

Embodiment 2N235

[0026] The selection of embodiment 2N235 extraction and leaching resin consumption

[0027] (1) Method

[0028] 1) Preparation of the extraction resin: weigh the AB-8 macroporous resin and wash it with absolute ethanol. Take 50g of the cleaned AB-8 macroporous resin and 20g of N235 in a container, add ethanol and mix well, stir in a water bath at 60°C for 2 hours, heat up to 80°C and evaporate the ethanol to dryness to obtain N235 extraction resin.

[0029] 2) Adsorption: Take 30 mL of germanium-containing solution with a concentration of 1 mg / mL, add N235 extraction resin and the same amount of tartaric acid respectively, adjust the pH to about 2.0 with sulfuric acid, shake and stir for 90 minutes, and filter to obtain N235 extraction resin that adsorbs germanium and raffinate;

[0030] 3) Elution: Add 10 mL of NH with a concentration of 4 mol / L to the N235 extraction resin that adsorbs germanium 4 F eluent for elution, shake and stir for 90min, filter, and take the filtra...

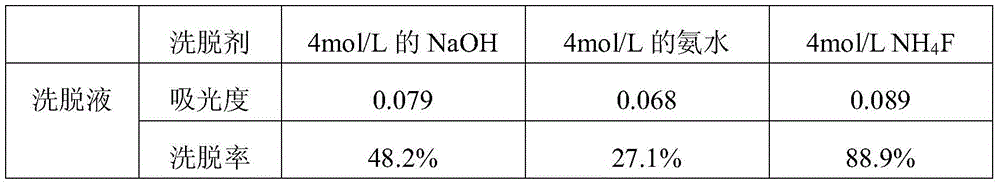

Embodiment 3

[0037] The selection of embodiment 3 eluents

[0038] (1) Method

[0039] 1) Preparation of the extraction resin: weigh the AB-8 macroporous resin and wash it with absolute ethanol. Take 50g of the cleaned AB-8 macroporous resin and N235 in a container, add 10mL of ethanol and mix well, stir in a water bath at 60°C for 2h, heat up to 80°C and evaporate the ethanol to dryness to obtain N235 extraction resin.

[0040] 2) Adsorption: Take 30 mL of germanium-containing solution with a concentration of 1 mg / mL, add 0.1 g of N235 extraction resin and 0.1 g of tartaric acid, adjust the pH to about 2.0 with sulfuric acid, shake and stir for 90 minutes, and filter to obtain N235 extraction resin that adsorbs germanium;

[0041] 3) Elution: Add 10mL of different eluents to the N235 extraction resin adsorbing germanium for elution, shake and stir for 80-100min, filter, and take the filtrate as the eluent.

[0042] (2) Results

[0043] After the eluent obtained in step 3) was diluted 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com