A Method for Rapidly Adjusting the Refractive Index Sensitivity of Long Period Fiber Bragg Gratings

A technology of long period grating and fiber grating, which is applied in cladding fiber, optical waveguide light guide, phase influence characteristic measurement, etc. Sensitivity, easy availability of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

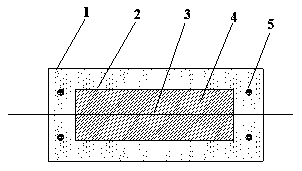

[0038] Prepare 0.1 mol / L ammonium hexafluorotitanate aqueous solution and 0.2 mol / L boric acid aqueous solution respectively, then mix the two solutions in equal volume, stir to make the mixed solution evenly mixed, and adjust the pH of the mixed solution with 0.01 mol / L ammonia water Adjust it to 3.9, pour the mixed solution into the reaction tank 2 of the long-period grating fixture 1, adjust the reaction temperature to 50°C, stop the reaction when the reaction time reaches 40min, and wash it with twice distilled water for 6 times. The refractive index sensitivity of fiber Bragg grating 3 to ethanol reaches 3300nm / RIU, which is 56 times higher than that without titanium dioxide nano film growth.

Embodiment 2

[0040] Add titanium tetrachloride to 1mol / L hydrochloric acid to prepare a titanium tetrachloride solution with a concentration of 0.5mol / L, stir evenly, pour the prepared solution into the reaction tank 2 of the long-period grating fixing device 1, and place The temperature of the reaction solution was adjusted to 90°C, the reaction was stopped when the reaction time was controlled for 55 minutes, and the reaction was fully rinsed with double distilled water. At this time, the refractive index sensitivity of the long-period fiber grating 3 to n-butanol reached 3500nm / RIU, which was higher than that of the ungrown titanium dioxide nanofilm. The time sensitivity has been increased by 115 times.

Embodiment 3

[0042] Prepare an aqueous solution of 0.001 mol / L titanium tetrafluoride, adjust the pH value of the solution to 2.88 with 0.01 mol / L dilute hydrochloric acid, and stir evenly. Pour the prepared solution into the reaction tank 2 of the long-period grating fixing device 1, adjust the temperature of the solution to 130°C, keep the temperature constant to make it react, stop the reaction after 50 minutes, and rinse it with twice distilled water for several times, at this time the long-period optical fiber The refractive index sensitivity of grating 3 to isopropanol reaches 1994nm / RIU, which is 39 times higher than that without growing titanium dioxide nano film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com