A method for detecting transverse cracks between layers of carbon steel/aluminum explosive composite pipe

A technology for transverse cracks and composite pipes, which is applied in the direction of material analysis using sonic emission technology, can solve the problems of great influence on the internal and surface quality of the structure, poor detection accuracy, and large environmental impact, and achieves convenient detection operation and low cost. , the effect of eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

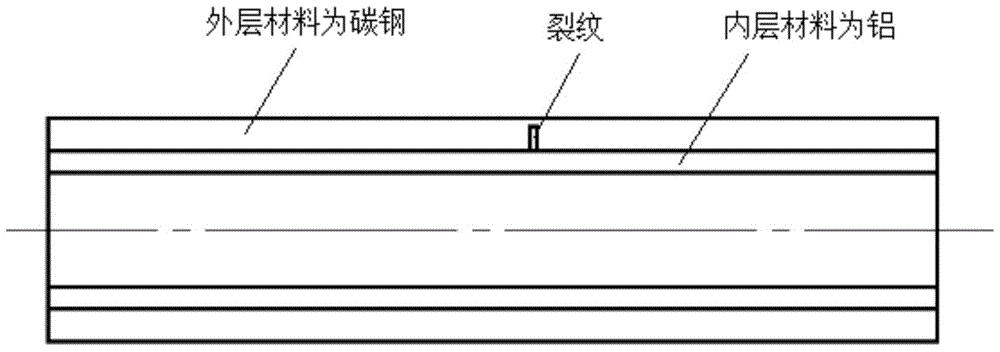

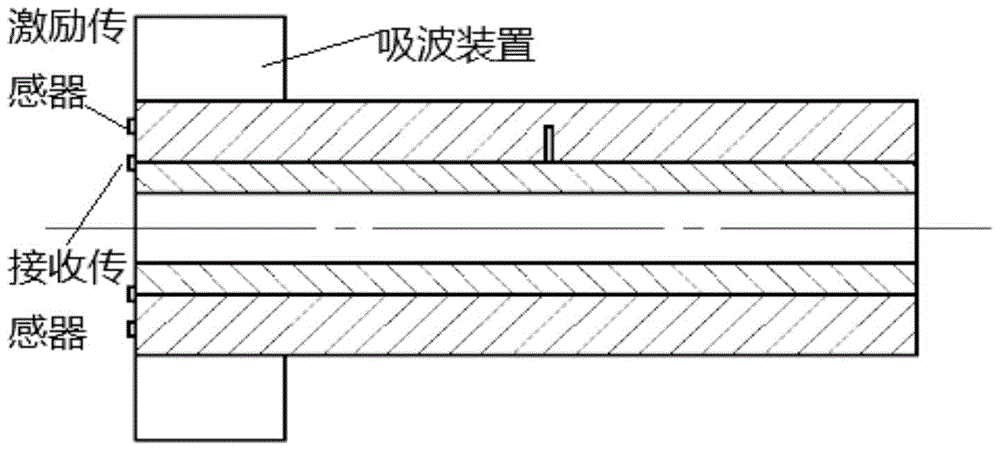

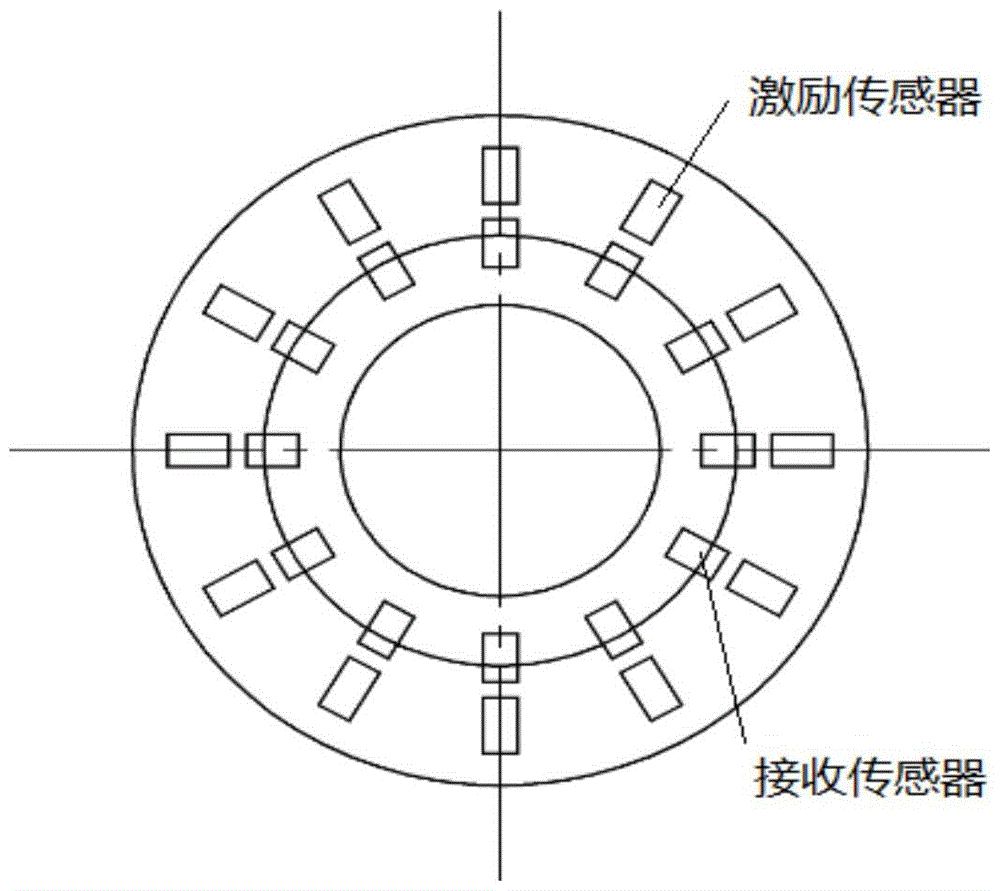

[0019] In a basic embodiment, the present invention provides a method for detecting interlaminar transverse cracks in a carbon steel / aluminum explosive composite pipe, the method excites and receives Stoneley waves at the end face of the explosive composite The damage of the interlayer crack is located by the propagation time difference method of the Stoneley wave; by changing the excitation frequency of the Stoneley wave, multiple sets of signal amplitude ratios of different frequencies are obtained, and the relationship curve between the signal amplitude ratio and the wavelength is drawn , the wavelength corresponding to the turning point from the slowly decreasing area to the rapidly decreasing area on the relationship curve is the quantitative estimate of the transverse crack of the explosive composite tube; the signal amplitude ratio is the reflected wave signal amplitude and the excitation The ratio of wave signal amplitude; the outer layer of the explosive composite pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com