Trichoderma wettable powder and preparation method thereof

A technology of wettable powder and Trichoderma, applied in botany equipment and methods, fungicides, biocides, etc., can solve the problems of low spore recovery rate, short shelf life of Trichoderma chlamydospores, etc., and reduce mixing and stirring The time, to meet the large-scale production, the effect of prolonging the survival period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

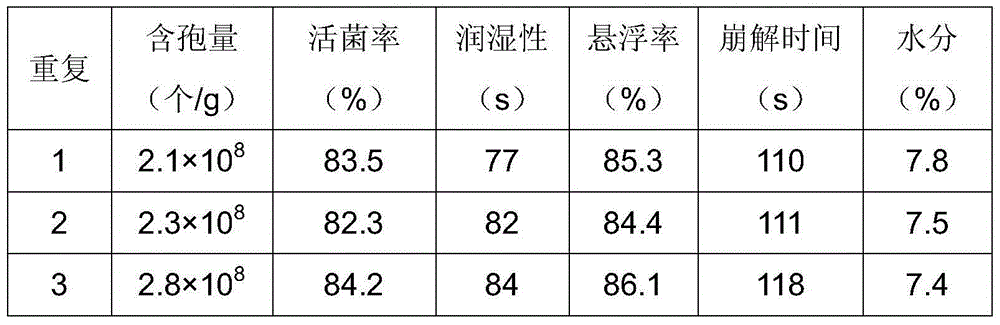

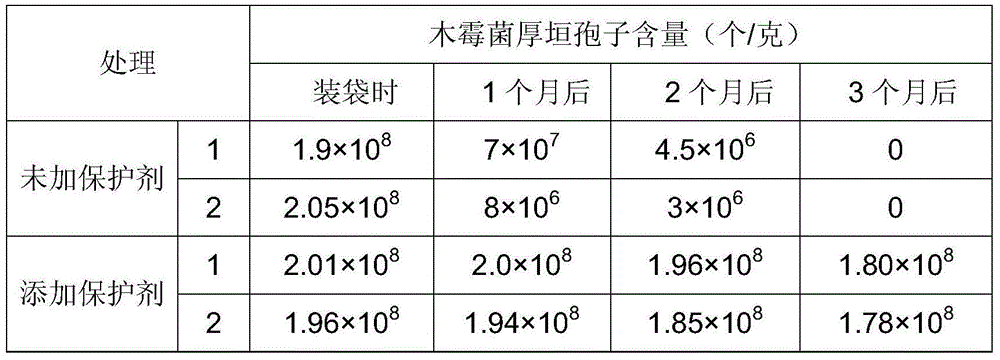

Embodiment 1

[0044] The components of the additives are: 800 mesh calcium bentonite (carrier) 40wt%, sodium lignosulfonate (dispersant) 2wt%, vitamin C 0.5wt‰, xanthan gum (adhesive) 0.5wt‰, SDS (wetting agent) agent) 2wt%. Put each component into a grinder, pulverize and mix to prepare the auxiliary agent, and set aside.

[0045] Take Trichoderma chlamydospores and carry out liquid fermentation for 7 days to obtain Trichoderma liquid; mix Trichoderma liquid with diatomaceous earth at a volume ratio of 10:1, and add glycerin and dextrin (original powder protective agent); put the mixture in Vacuum dry at 30°C for 4 hours until the water content is 22%. After drying, the original powder of Trichoderma is obtained. Wherein, the content of dextrin in the former powder of gained Trichoderma is 5wt%, and the content of glycerol is 4wt%, and the content of spore is 3.8 * 10 8 pcs / g.

[0046] Finally, the original powder of Trichoderma and additives were crushed and mixed in a low-temperature ...

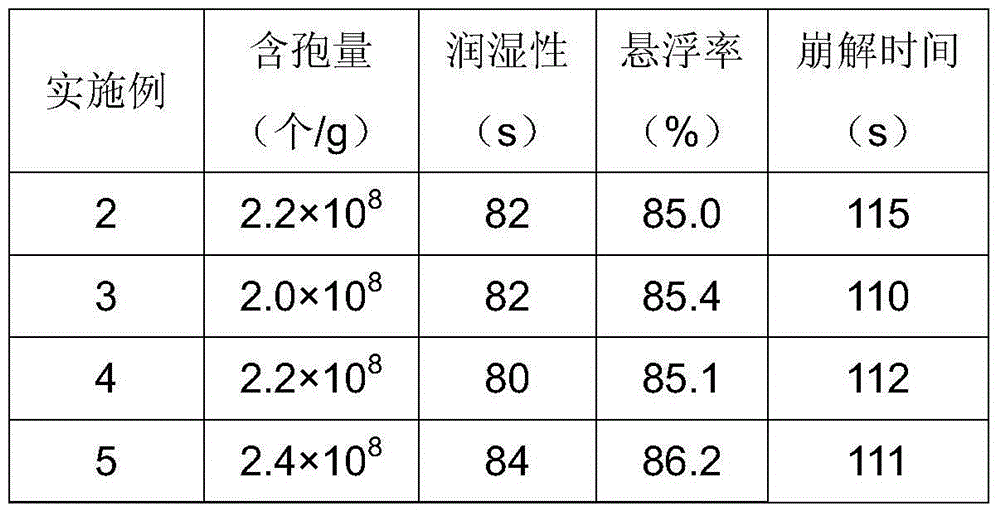

Embodiment 2

[0055] The components of the additives are: 800 mesh calcium bentonite (carrier) 40wt%, sodium lignosulfonate (dispersant) 2wt%, vitamin C 0.5wt‰, xanthan gum (adhesive) 0.5wt‰, SDS (wetting agent) agent) 2wt%. Put each component into a grinder, pulverize and mix to prepare the auxiliary agent, and set aside.

[0056] Take Trichoderma chlamydospores and carry out liquid fermentation for 7 days to obtain Trichoderma liquid; mix Trichoderma liquid with diatomaceous earth at a volume ratio of 10:1, and add glycerin and dextrin (original powder protective agent); put the mixture in Vacuum dry at 30°C for 4 hours until the water content is 22%. After drying, the original powder of Trichoderma is obtained. Wherein, the content of dextrin in the former powder of gained Trichoderma is 8wt%, and the content of glycerol is 6wt%, and the content of spore is 3.8 * 10 8 pcs / g.

[0057] Finally, the original powder of Trichoderma and additives were crushed and mixed by low-temperature ai...

Embodiment 3

[0059] The components of the additives are: 800 mesh calcium bentonite (carrier) 45wt%, sodium lignosulfonate (dispersant) 2.5wt%, vitamin C 0.3wt‰, xanthan gum (adhesive) 0.4wt‰, SDS (moisturizer) Wet agent) 2.2wt%. Put each component into a grinder, pulverize and mix to prepare the auxiliary agent, and set aside.

[0060] Take Trichoderma chlamydospores and carry out liquid fermentation for 6 days to obtain Trichoderma liquid; mix Trichoderma liquid with diatomaceous earth at a volume ratio of 8:1, and add glycerin and dextrin (original powder protective agent); put the mixture in Vacuum dry at 30°C for 4 hours until the water content is 20%. After drying, the original powder of Trichoderma is obtained. Wherein, the content of dextrin in the former powder of gained Trichoderma is 4wt%, and the content of glycerol is 2wt%, and the content of spore is 3.2 * 10 8 pcs / g.

[0061] Finally, the original powder of Trichoderma and additives were crushed and mixed in a low-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com