Mixed granulating equipment and application of mixed granulating equipment for preparing solid preparation

A mixing system and equipment technology, which is applied in the direction of making medicines into special physical or ingestible devices, can solve the problems of long granulation time, poor physical and chemical properties of granules, and low dispersion of viscous materials, so as to avoid safety Hidden dangers, reasonable particle size distribution, and short granulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of capecitabine sheet

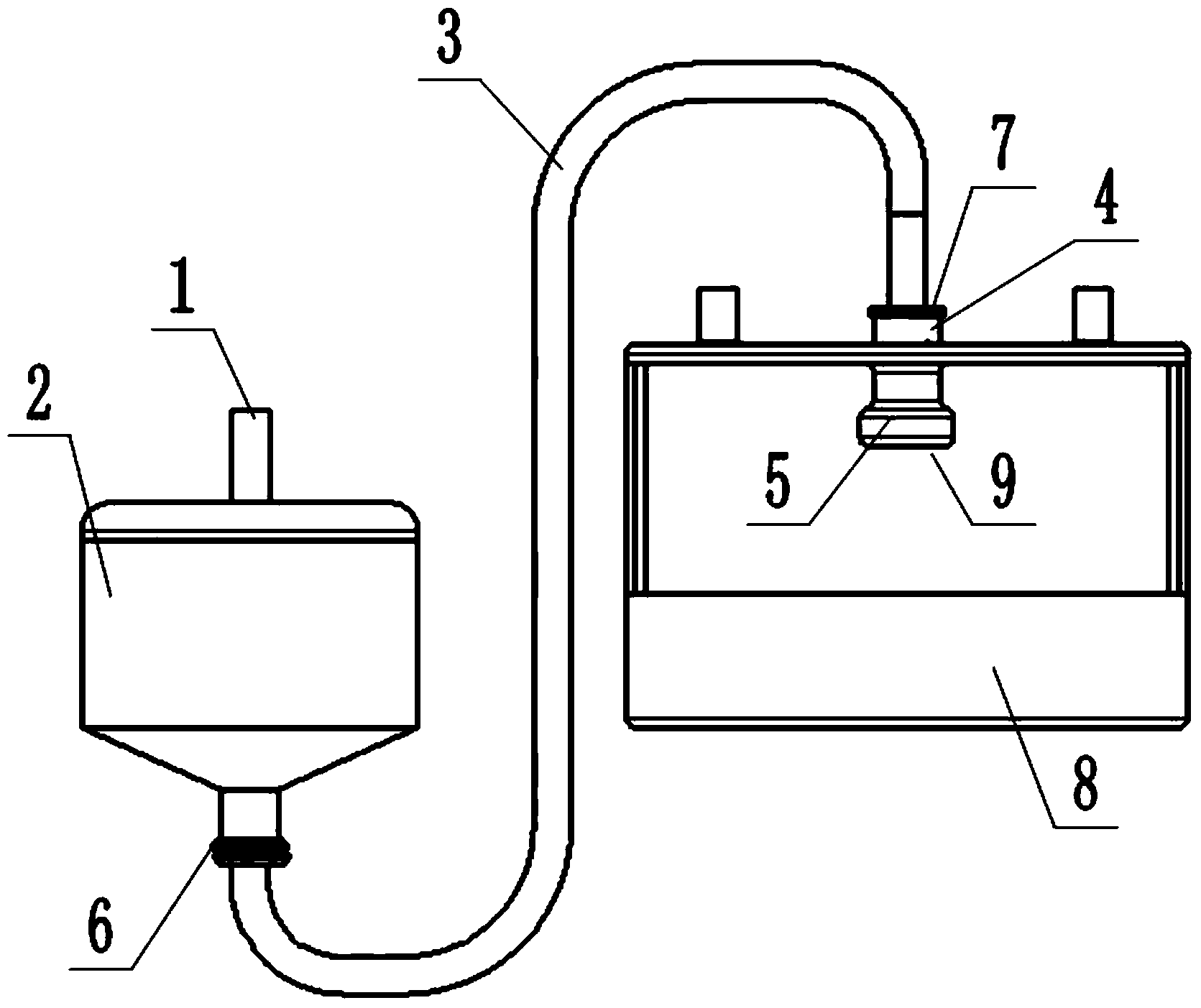

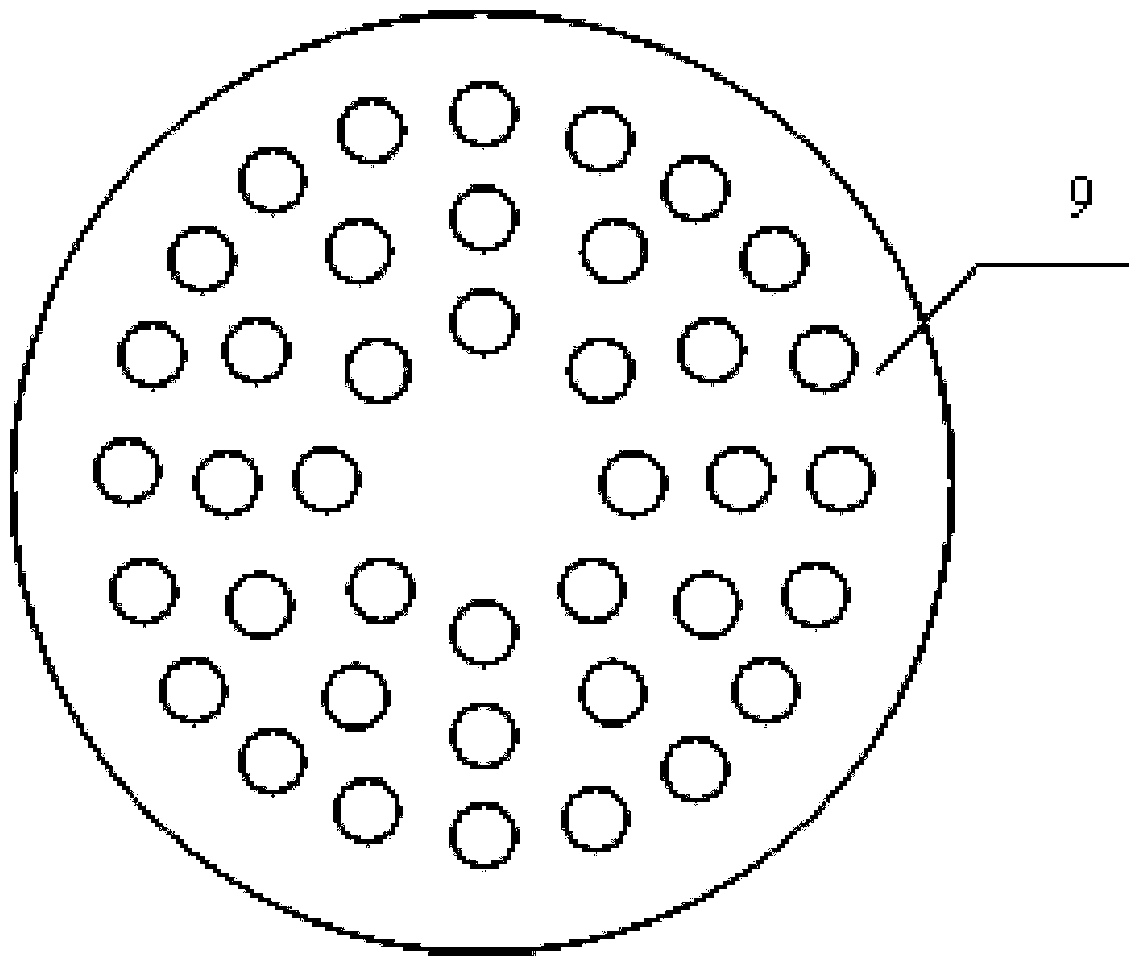

[0037] A mixing and granulation equipment, such as figure 1 and figure 2 As shown, it includes a pressure tank 2 and a mixing granulator 8, the pressure tank 2 is placed on the left side of the mixing granulator 8, the upper part is equipped with a compressed air interface 1, and the bottom is equipped with a connecting hose 3, and the connecting soft The pipe 3 is used to connect the pressure tank 2 and the mixing granulator 8; it also includes a shower 5 placed on the middle and upper part of the mixing granulator 8, connected to the connecting hose 3 through the connecting pipe 4, and the shower 5 is A hollow cylinder with circular holes 9 on the top, which are circularly distributed on the top of the shower head 5. There are 50 holes 9 with a diameter of 2 mm. Used between the shower head 5 and the connecting pipe 4 Threaded connection, the connecting pipe 4 and the connecting hose 3 are connected by a clamp f...

Embodiment 2

[0048] Embodiment 2: the preparation of moxifloxacin hydrochloride tablet

[0049] The connection mode of the mixing and granulating equipment of embodiment 2 is the same as that of embodiment 1, the difference is:

[0050] There are circular holes 9 on the top of the shower 5, distributed in a circle on the top of the shower 5, and there are 70 holes 9 with a diameter of 1.0 mm.

[0051] The production process of moxifloxacin hydrochloride tablets is as follows: add 3.4kg of moxifloxacin hydrochloride, 0.9kg of pregelatinized starch, 0.6kg of microcrystalline cellulose, and 0.15kg of croscarmellose sodium into the HLSG20A mixing granulator , turn on the stirring speed of 150rpm, the chopping speed of 1300rpm, and mix well. Use water as a wetting agent for wet granulation, then dry and granulate; add an appropriate amount of magnesium stearate, mix evenly, compress into tablets, and coat.

[0052] When working, add water to the pressure tank 2, adjust the opening of the comp...

Embodiment 3

[0058] Embodiment 3: the preparation of Bailing Tablet

[0059] The connection mode of the mixing and granulating equipment of embodiment 3 is the same as that of embodiment 1, the difference is:

[0060] There are square holes 9 on the top of the shower 5, which are circularly distributed on the top of the shower 5. There are 80 holes 9 with a diameter of 1.5mm.

[0061] The production process of Bailing Tablets is as follows: Add 30kg of fermented Cordyceps sinensis powder, 5kg of pregelatinized starch, and 4kg of microcrystalline cellulose into the SHK-220A mixing granulator, turn on the stirring "Ⅰ" file, chop " Ⅰ” level, mix evenly. 10% hydroxypropyl cellulose ethanol solution is used as a binder for wet granulation, then dried and sized; an appropriate amount of magnesium stearate is added to mix evenly, and the tablet is obtained.

[0062] During work, 10% hydroxypropyl cellulose ethanol solution is added in the pressure tank 2, and the opening degree of the compresse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com