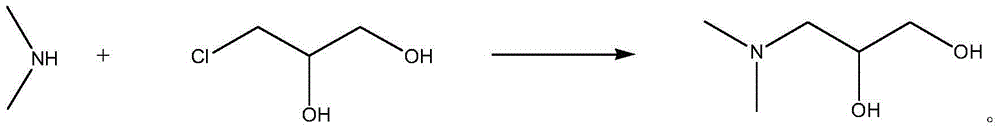

Preparation method of 3-dimethylamino-1,2-propanediol

A technology of dimethylamino group and propylene glycol, which is applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, chemical instruments and methods, etc., can solve the problems of not meeting the requirements of drug production, poor quality, low yield, etc., and achieve The effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put 247g of 40wt% dimethylamine aqueous solution into a 1000ml reaction bottle, add dropwise 3-chloro-1,2-propanediol methanol diluent (200g of 3-chloro-1,2-propanediol + 267ml of methanol) below 25°C, about 25% dropwise At the same time, the remaining methanol dilution of 3-chloro-1,2-propanediol and methanol dilution of sodium methoxide (sodium methoxide 345g+methanol 147ml) were added dropwise at the same time. ℃, heat preservation reaction for 3 hours, then raise the temperature to reflux, keep it for 2 hours, cool to room temperature and filter, and rinse the filter cake with an appropriate amount of methanol. The filtrates were combined, methanol was evaporated under reduced pressure, 330ml of toluene was added, the total reflux dehydration was carried out to an internal temperature above 110°C, cooled to room temperature, filtered, the toluene was evaporated under reduced pressure, and 171.9 g of the product was obtained by rectification, yield: 79.8%, The GC con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com