High-brightness high-hardness water-based acrylic baking varnish and preparation method thereof

A water-based acrylic, high-hardness technology, applied in coatings, epoxy resin coatings, etc., can solve the problems that water-based acrylic clear baking paint cannot meet the requirements of electrostatic spraying, high volatile organic content, poor acid, alkali, and salt resistance, etc. , to achieve good construction and operation performance, excellent corrosion resistance and chemical resistance, and good environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

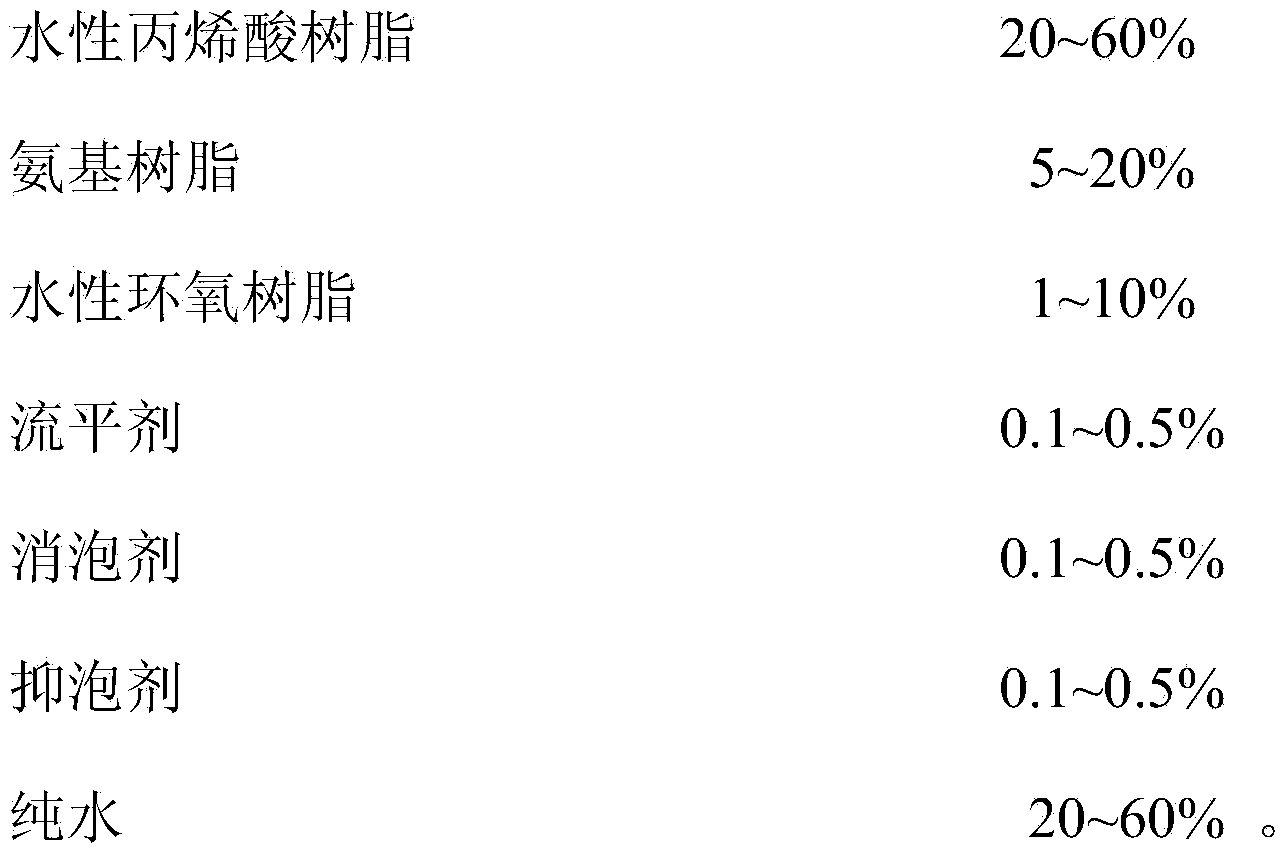

[0094] A kind of high-brightness and high-hardness water-based acrylic varnish of the present invention comprises the raw material of following mass percentage:

[0095]

[0096] The waterborne acrylic resin of the present embodiment comprises the raw material of following mass percent:

[0097]

[0098] The amino resin of the present embodiment is melamine formaldehyde resin.

[0099] The leveling agent in this embodiment is polyether polyester modified organosiloxane.

[0100] The defoamer in this embodiment is a polyether defoamer.

[0101] The foam suppressor of the present embodiment is a polyether foam suppressor.

[0102] A preparation method of high-brightness and high-hardness water-based acrylic clear baking varnish, comprising the following processing steps:

[0103] Step A, weighing the material of the formula amount, and placing it in a different container for use;

[0104] Step B, put all the water-based acrylic resin, amino resin and water-based epoxy ...

Embodiment 2

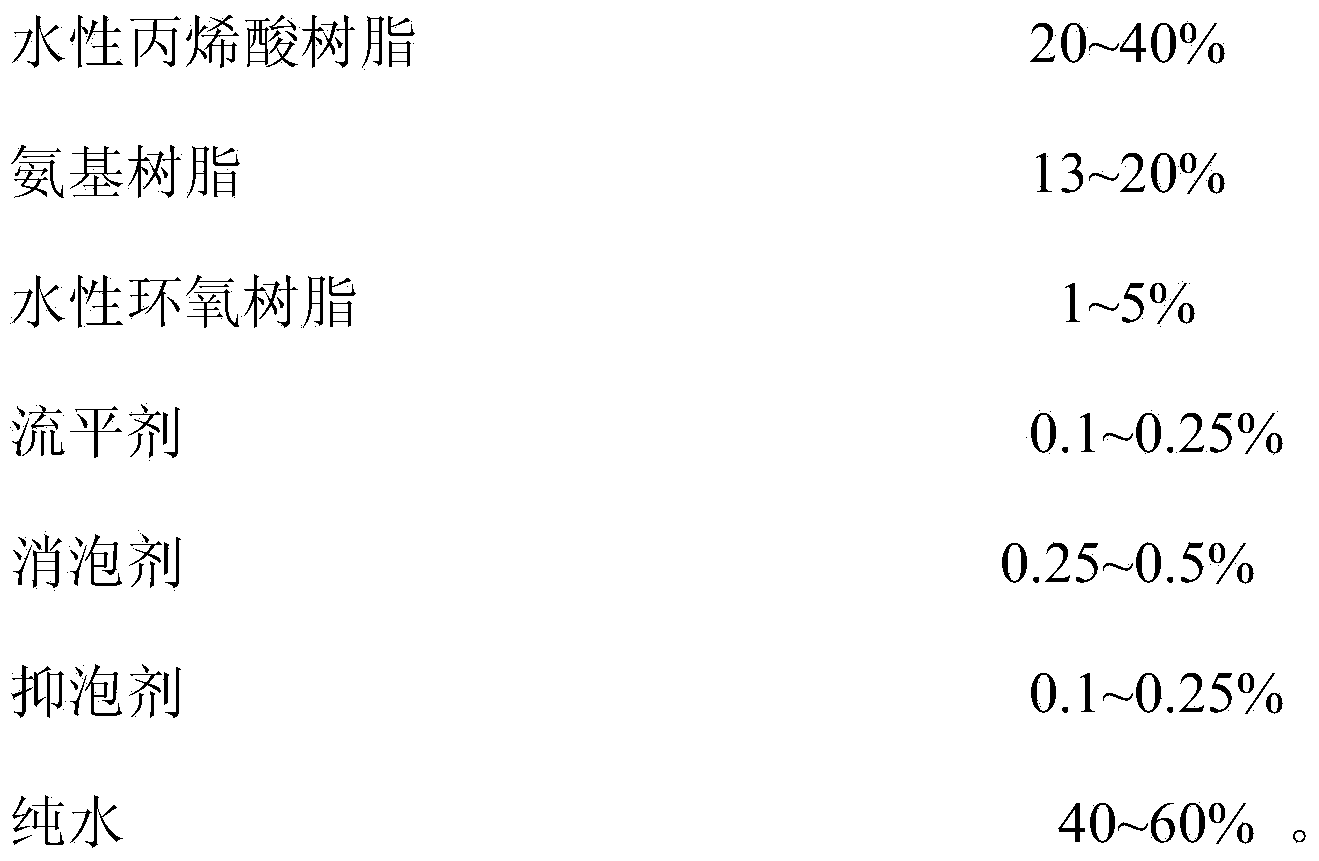

[0117] A kind of high-brightness and high-hardness water-based acrylic varnish of the present invention comprises the raw material of following mass percentage:

[0118]

[0119]

[0120] The waterborne acrylic resin of the present embodiment comprises the raw material of following mass percent:

[0121]

[0122] The amino resin of this embodiment is urea-formaldehyde resin.

[0123] The leveling agent in this embodiment is silicone oil.

[0124] The defoamer in this embodiment is a silicone ether copolymerized defoamer.

[0125] The foam suppressor of the present embodiment is a silicone foam suppressor.

[0126] A preparation method of high-brightness and high-hardness water-based acrylic clear baking varnish, comprising the following processing steps:

[0127] Step A, weighing the material of the formula amount, and placing it in a different container for use;

[0128] Step B, put all the water-based acrylic resin, amino resin and water-based epoxy resin into t...

Embodiment 3

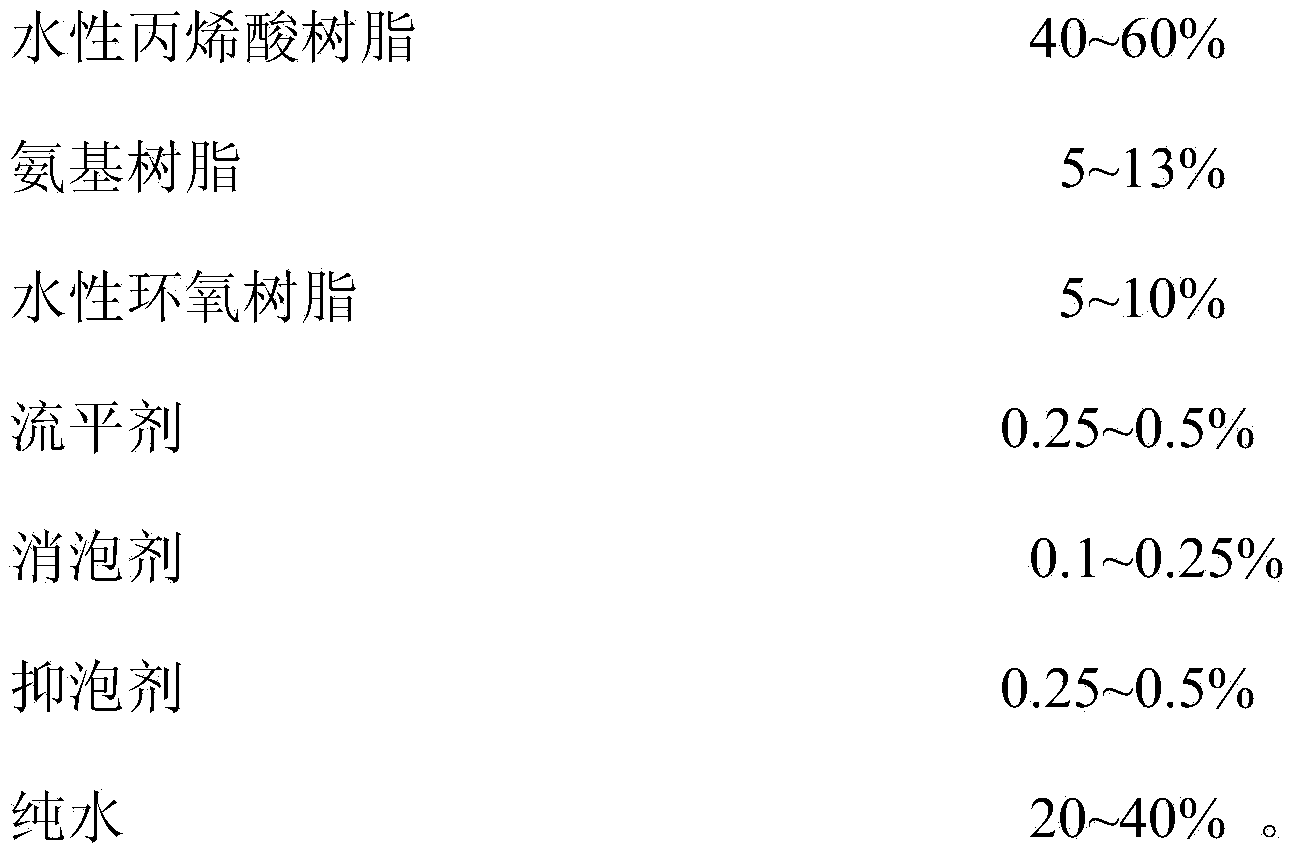

[0141] A kind of high-brightness and high-hardness water-based acrylic varnish of the present invention comprises the raw material of following mass percentage:

[0142]

[0143]

[0144] The waterborne acrylic resin of the present embodiment comprises the raw material of following mass percent:

[0145]

[0146] The amino resin of this embodiment is polyamide polyamine epichlorohydrin.

[0147] The leveling agent in this embodiment is polydimethylsiloxane.

[0148] The defoamer in this embodiment is a silicone ether copolymerized defoamer.

[0149] The foam suppressor of the present embodiment is a polyacrylate foam suppressor.

[0150] A preparation method of high-brightness and high-hardness water-based acrylic clear baking varnish, comprising the following processing steps:

[0151] Step A, weighing the material of the formula amount, and placing it in a different container for use;

[0152] Step B, put all the water-based acrylic resin, amino resin and water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com