A kind of silicon-carbon-nitrogen composite negative electrode material and preparation method thereof

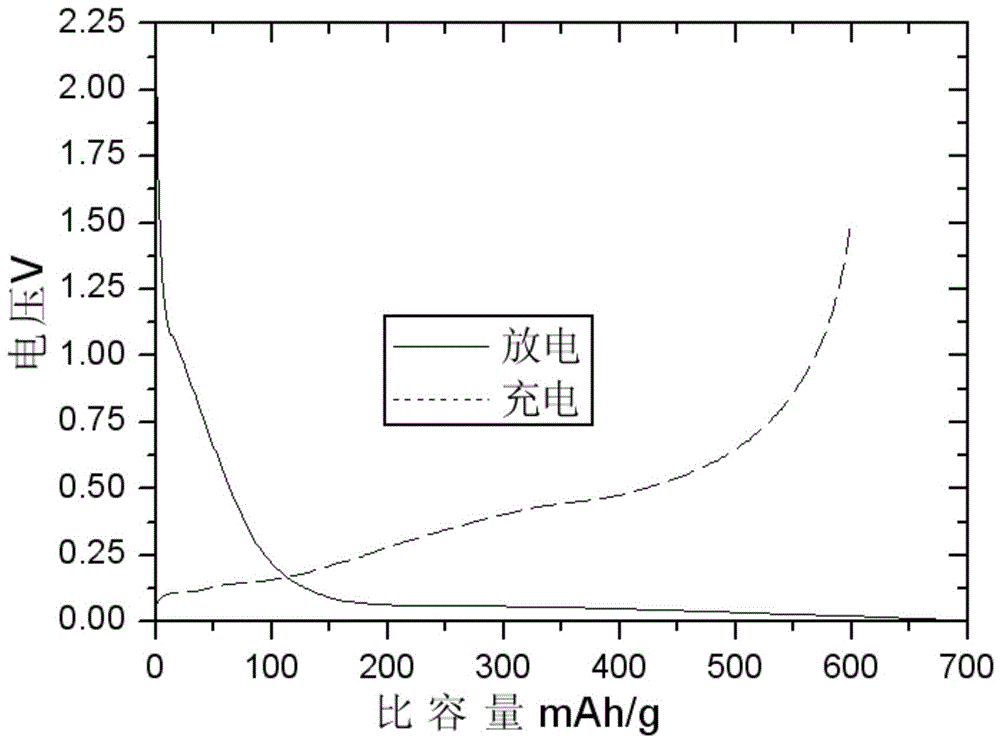

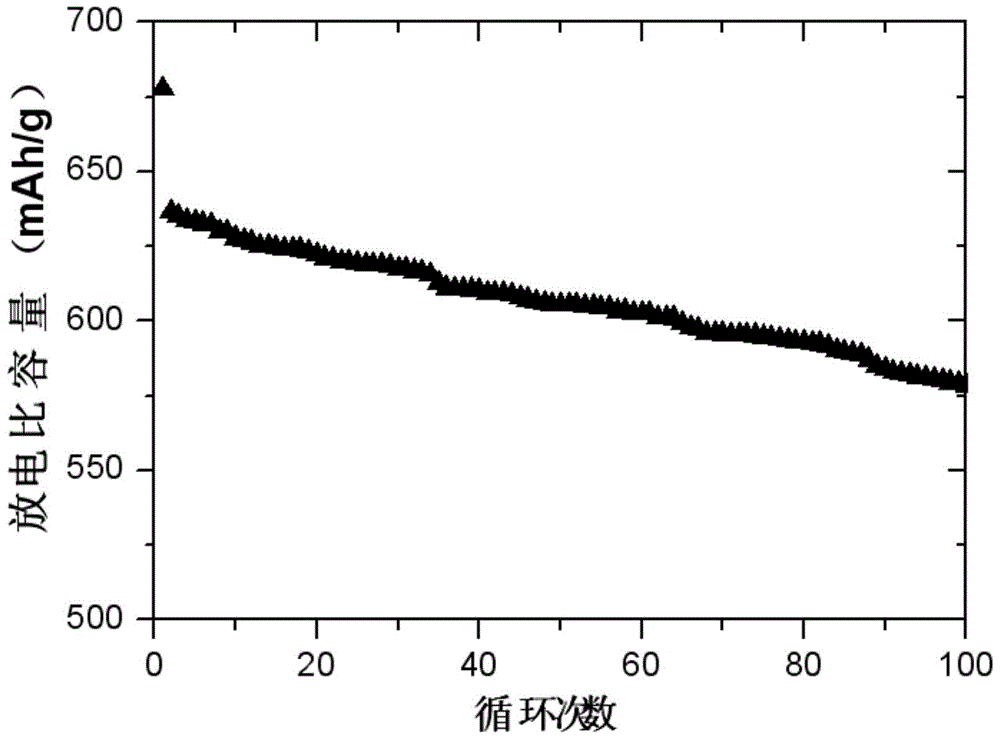

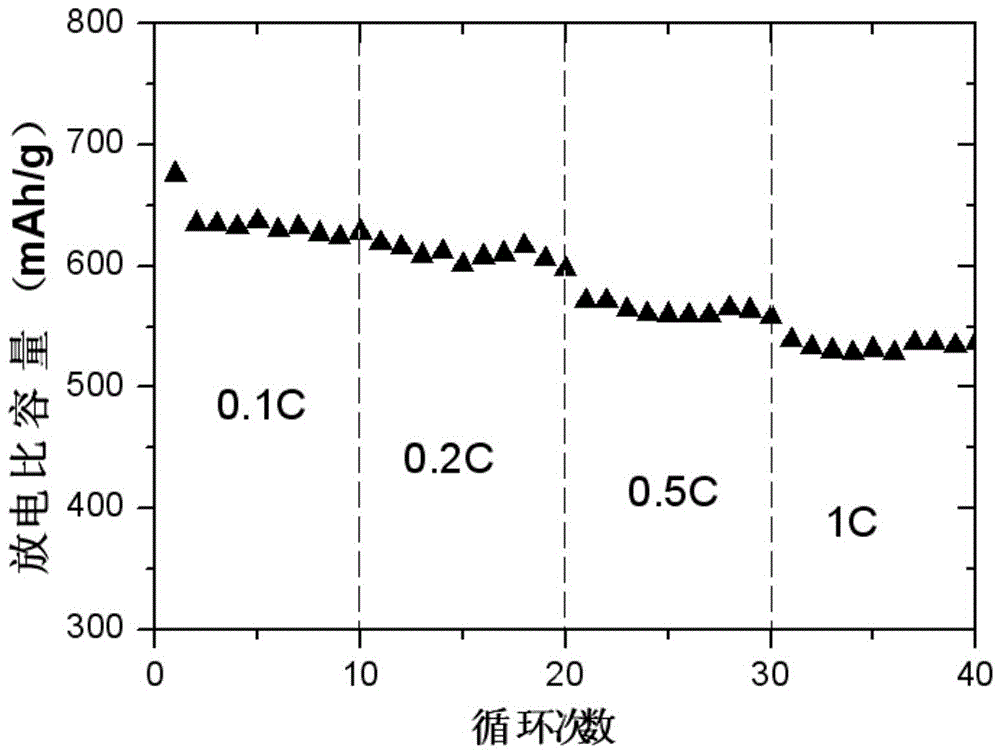

A technology of negative electrode materials and silicon-based materials, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of negative electrode material cycle stability and poor rate performance, and achieve excellent rate performance, reduced energy band width, and excellent cycle performance. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In the first aspect, an embodiment of the present invention provides a method for preparing a silicon-carbon-nitrogen composite negative electrode material, including:

[0029] Step 101. Under an argon atmosphere, heat the mixture of silicon source and nitrogen source to 600-1000°C at a heating rate of 0.5-10°C / min, and sinter at 600-1000°C for 3-15 hours, and then Cool down to room temperature to obtain a nitrogen-doped silicon-based material.

[0030] In the embodiment of the present invention, a mixture of a silicon source and a nitrogen source is sintered in an argon atmosphere, so that nitrogen is doped into the silicon material to form a nitrogen-doped silicon-based material. Since the silicon material is doped with nitrogen, the energy band width of the silicon material can be reduced, the conductivity of the silicon material can be effectively improved, and the cycle stability and rate performance of the prepared negative electrode material can be improved.

[...

Embodiment 1

[0046] Preparation of nitrogen-doped silicon-based materials:

[0047] Mix silicon monoxide and ethylenediamine evenly, then heat the mixture of silicon monoxide and ethylenediamine to 800°C at a heating rate of 3°C / min under an argon atmosphere, and sinter at this temperature for 7 hours. Then cool down to room temperature to obtain a nitrogen-doped silicon-based material. Wherein, the mass fraction of nitrogen in the nitrogen-doped silicon-based material is 4%.

[0048] Coating artificial graphite on the surface of nitrogen-doped silicon-based materials:

[0049] According to the mass ratio: nitrogen-doped silicon-based material: artificial graphite = 2:11, mix the nitrogen-doped silicon-based material and artificial graphite evenly, and in a nitrogen atmosphere, heat the nitrogen-doped silicon-based material at a heating rate of 5°C / min. The mixture of material and artificial graphite was heated to 650°C and sintered at this temperature for 6 hours. Then the temperature ...

Embodiment 2

[0051] Preparation of nitrogen-doped silicon-based materials:

[0052] Mix tetraethyl orthosilicate and acetamide evenly, and then heat the mixture of silicon monoxide and ethylenediamine to 650°C at a heating rate of 1°C / min under an argon atmosphere, and sinter at this temperature for 5 hours. Then cool down to room temperature to obtain a nitrogen-doped silicon-based material. Wherein, the mass fraction of nitrogen in the nitrogen-doped silicon-based material is 0.5%.

[0053] Coating artificial graphite on the surface of nitrogen-doped silicon-based materials:

[0054] According to the mass ratio: nitrogen-doped silicon-based material: artificial graphite = 4:1, mix the nitrogen-doped silicon-based material and artificial graphite evenly, and in a nitrogen atmosphere, heat the nitrogen-doped silicon-based material at a heating rate of 5°C / min. The mixture of material and artificial graphite was heated to 700°C and sintered at this temperature for 8 hours. Then the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com