Gene modification method for increasing yield of phloroglucinol and application of same

A technology of phloroglucinol and gene, applied in the field of genetic engineering, can solve the problem that the output and yield of phloroglucinol cannot meet the needs of industrial production, achieve high industrial application value, and increase output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The construction of embodiment 1 bacterial strain

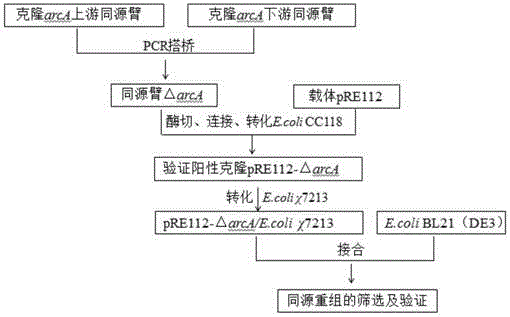

[0061] Taking Escherichia coli E.coliBL21 (DE3) as the starting strain, the arcA gene in the genome was knocked out, and the engineering strain ZG1949 was constructed (the construction process is as follows: figure 1 shown), the related plasmids pET-phlD-mar and pACYC-accADBC for the production of phloroglucinol were introduced into ZG1949 and the control strain E.coliBL21(DE3) to detect phloroglucinol fermentation at shake flask and fermenter levels.

[0062] Those skilled in the art should understand that, the above-mentioned Escherichia coli E.coliBL21 (DE3) gene knockout experiment, each step is carried out according to the standard molecular cloning technology.

[0063] 1.1 Construction of homology arm

[0064] Using the upstream and downstream of the arcA gene of the Escherichia coli E.coliBL21 (DE3) wild strain (including the partial sequence of the arcA gene) about 600bp base fragments as templates, primers we...

Embodiment 2

[0084] Embodiment 2. Fermentation experiments of engineering strains

[0085] 2.1 Shake flask fermentation experiment

[0086] 1) For the cultivation of primary seed liquid, inoculate wild control strains E.coliBL21(DE3) and ZG1949 containing pET-phlD-marA and pACYC-accADBC recombinant plasmids into 3mL LB liquid medium respectively, and add 50μg / mL card Namycin and 50 μg / mL chloramphenicol were grown at 37°C for 8-12h.

[0087] 2) Transfer the primary seed solution to a 250mL fermentation shaker flask with 1% inoculation amount, containing 50mL fermentation medium, and add 200g / L MgSO4.7H2O 100μL, 500g / L glucose 2mL, 1000× 50 μL of trace elements, 50 μg / mL kanamycin, 50 μg / mL chloramphenicol double resistance, set 3 parallel controls for each strain, and culture at 37°C and 180rpm.

[0088] 3) When the OD600 of the cells reaches 0.6-1.0, 100 μM / L IPTG can be added for induction.

[0089] 4) After induction by IPTG, continue to culture at 37°C and 180rpm for 24 hours, then ...

Embodiment 3

[0102] Embodiment 3. Fermentation experiments of engineering strains

[0103] 3.1 Shake flask fermentation experiment

[0104] 1) For the cultivation of the primary seed liquid, the inoculation method is according to Example 2.1.

[0105] 2) Transfer the primary seed solution to a 250mL fermentation shaker flask with 3% inoculum size, containing 50mL fermentation medium, and add 200g / L MgSO when transferring the seed solution 4 .7H 2 O 100 μL, 500 g / L glucose 2 mL, 1000 × trace elements 50 μL, 50 μg / mL kanamycin, 50 μg / mL chloramphenicol double resistance, set 3 parallel controls for each strain, culture at 37°C, 180rpm.

[0106] 3) When the OD600 of the cells reaches 0.6-1.0, 100 μM / L IPTG can be added for induction.

[0107] 4) After induction by IPTG, continue to culture at 37°C and 180rpm for 24 hours, then collect the bacterial liquid, centrifuge to get the supernatant, and measure the content of phloroglucinol.

[0108] 3.2 Fed-batch fermentation production of phloro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com