WC series steel bond hard alloy

A technology of steel-bonded hard alloy and hard phase, which is applied in the field of powder metallurgy, can solve the problems of being unable to meet the requirements for the use of brazing chips and snow-shoveling chips, and low material hardness, and achieve good wear resistance, high hardness, and low porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

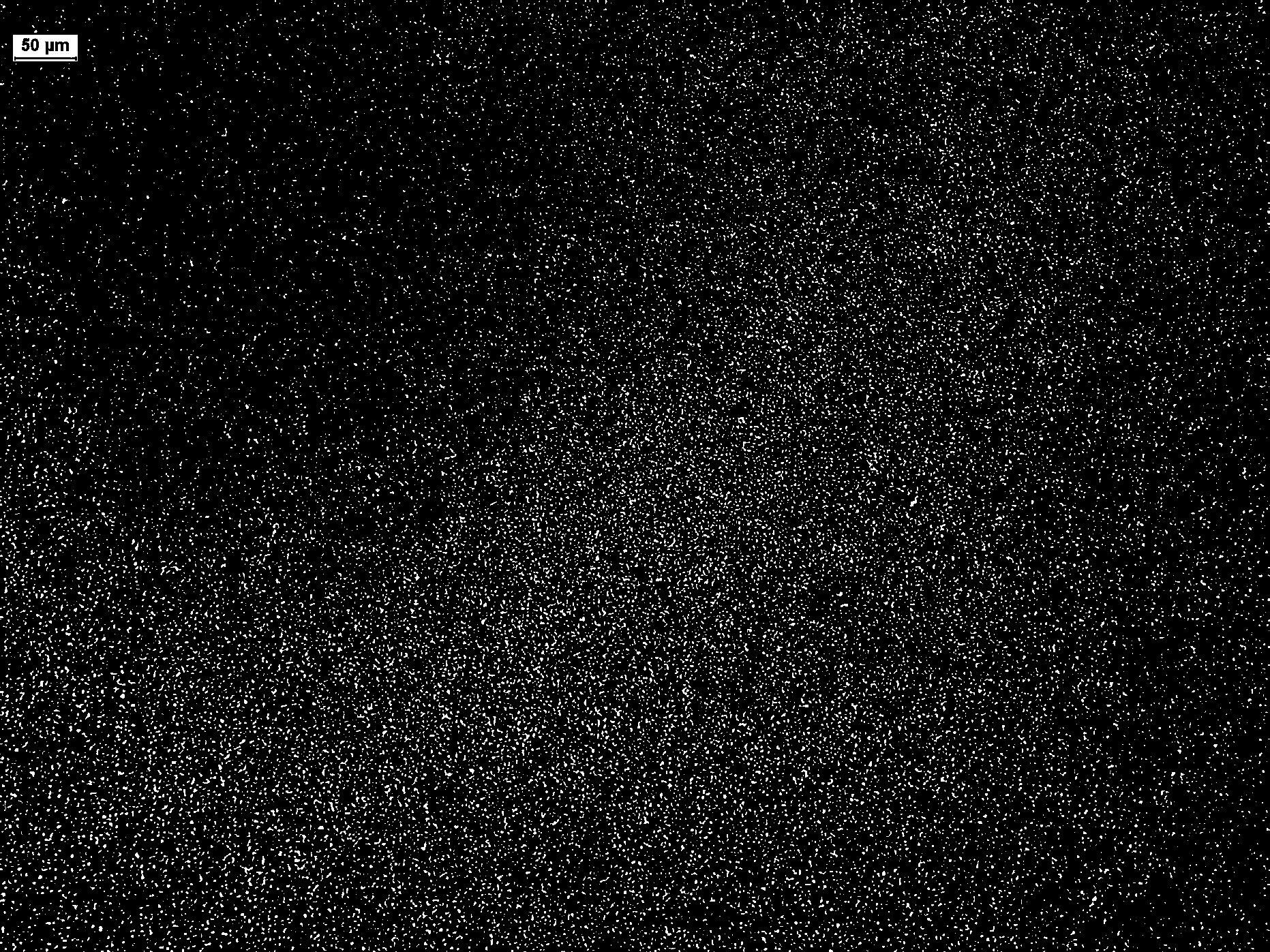

Image

Examples

Embodiment 1

[0019] Embodiment 1: the weight percentage (ie wt%, the following examples are all the same) is 65% of WC, 1.6% of Cr 3 C 2 Powder, 1.5% Ni, 0.8% Mo, 6.5% ferromanganese powder, 0.7% carbon black and the rest of iron and other powders are mixed according to requirements, with cemented carbide rods as grinding bodies, and the ball-to-material ratio is 4:1, using alcohol as the medium for wet grinding for 28 hours, unloading, spray drying, granulation, pressing and molding, and finally integral sintering, using zirconia boat as the contact material, sintering at 1300°C for 1 hour and then cooling with the furnace , to obtain steel-bonded cemented carbide products with high hardness and high dimensional accuracy. The specific alloy properties are shown in Table 1.

Embodiment 2

[0020] Embodiment 2: be 70% WC by weight percentage, 1.4% Cr 3 C 2 Powder, 1.3% Ni, 0.7% Mo, 5.5% ferromanganese powder, 0.6% carbon black and the rest of iron and other powders are mixed according to requirements, with cemented carbide rods as grinding bodies, and the ball-to-material ratio is 4:1, using alcohol as the medium for wet grinding for 28 hours, then unloading, spray drying, granulation, pressing and molding, and finally integral sintering, using zirconia boat as the contact material, sintering at 1320°C for 1 hour and then cooling with the furnace , to obtain WC steel-bonded carbide products with high hardness and high dimensional accuracy. The specific alloy properties are shown in Table 1.

Embodiment 3

[0021] Embodiment 3: be 75% WC by weight percentage, 1.2% Cr 3 C 2 Powder, 0.9% Ni, 0.6% Mo, 4.6% ferromanganese powder, 0.5% carbon black and the rest of iron and other powders are mixed according to requirements, with cemented carbide rods as grinding bodies, and the ball-to-material ratio is 4 : 1. Unload after 28 hours of wet grinding with alcohol as the medium, spray dry and granulate, press into shape, and finally carry out integral sintering, use zirconia boat as the contact material, sinter at 1360 ° C for 1 hour and then cool with the furnace. Steel-bonded cemented carbide products with high hardness and high dimensional accuracy are obtained. The specific alloy properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com