Preparation method of aerogel modified SnSb/carbon nanotube composite positive electrode material

A carbon nanotube composite and negative electrode material technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of unsatisfactory cycle performance and low capacity, and achieve improved cycle stability, The effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention proposes a method for preparing an airgel-modified SnSb / carbon nanotube composite negative electrode material, comprising the following steps:

[0028] Step 1: Using industrial sodium silicate or tetraethyl orthosilicate as the silicon source, formamide and ethylene glycol as additives, and acetic acid as a catalyst, use sol-gel method and normal pressure drying method to prepare SiO2 airgel powder material stand-by;

[0029] Step 2: Separately with SnCl 2 2H 2 O and SbCl 3 For Sn and Sb sources, prepare a certain concentration of SnCl 2 and SbCl 3 Solution, add a certain amount of polyvinylpyrrolidone, then stir evenly to obtain A solution;

[0030] In step 2, prepare SnCl 2 and SbCl 3 The solution concentration is 0.05 ~ 0.3mol / L, SnCl 2 and SbCl 3 The ratio of the amount of substances is controlled in: SnCl 2 / SbCl 3 =3 ~ 1;

[0031] In step 2, the quality of adding polyvinylpyrrolidone is 5%~15% of the theoretically obtained SnSb al...

Embodiment 1

[0044] With 40wt% industrial water glass as the silicon source, appropriate amount of formamide and ethylene glycol are dropped into the water glass solution respectively, and the ratio of the three substances is 3:1:1. Use 0.5mol·L -1 Acetic acid was used to adjust the pH of the sol to 12, and the gel was obtained by standing at room temperature. The obtained gel was aged in deionized water for 72 hours, then washed with deionized water for several times, and finally soaked in absolute ethanol for 72 hours, and dried by atmospheric pressure classification (40 ° C, 50 ° C, 60 ° C and 80 ° C in sequence dried for 24h), and SiO 2 Airgel powder material.

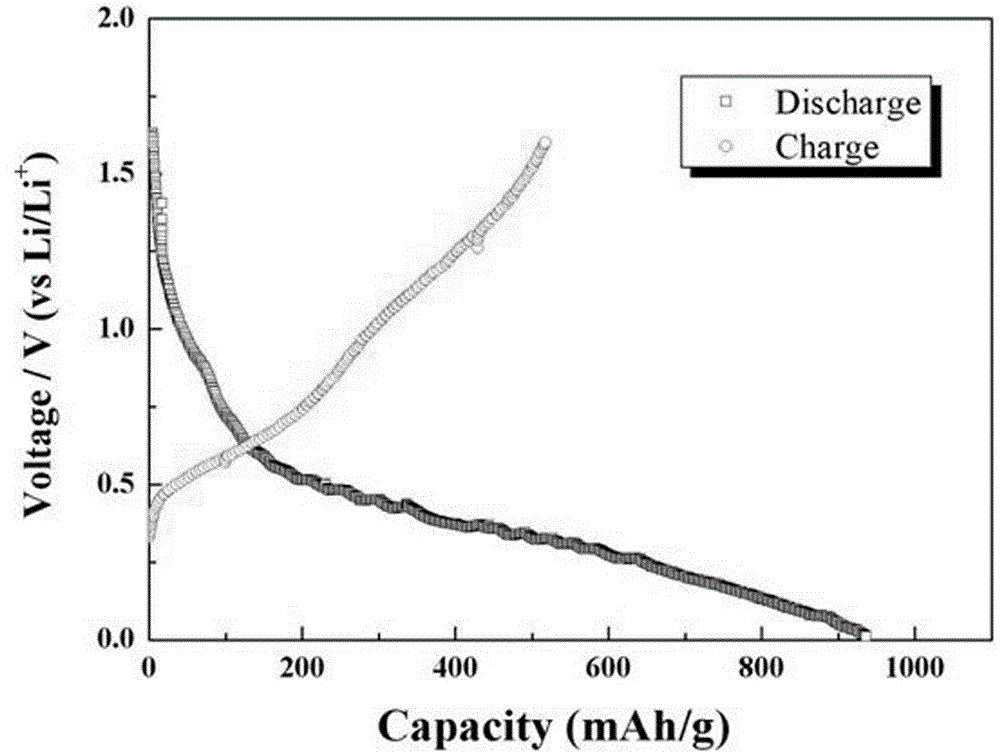

[0045] Weigh 4.51g SnCl 2 2H 2 O and 2.28gSbCl 3 Dissolve in 200ml absolute ethanol, then add 0.45g polyvinylpyrrolidone therein and stir evenly to obtain A solution. Weigh 2.92g of NaBH 4 Dissolve in 520ml deionized water and add 1.5g NaOH to prepare 0.15mol / L NaBH 4 solution, called B solution. Add 0.05 g of carbon n...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is: the described SnCl 2 2H 2 O and SbCl 3 The masses are 9.02g and 4.56g respectively, the mass of polyvinylpyrrolidone is 0.36g, and the mass of NaBH 4 Mass is 5.84g, carbon nanotube mass is 0.07g, SiO 2 The mass of the airgel is 1.44g, the heat preservation condition of the hydrothermal synthesis reaction is 24 hours at 160°C, and the vacuum drying condition of the obtained product is 10 hours at 60°C. Others are the same as in Example 1.

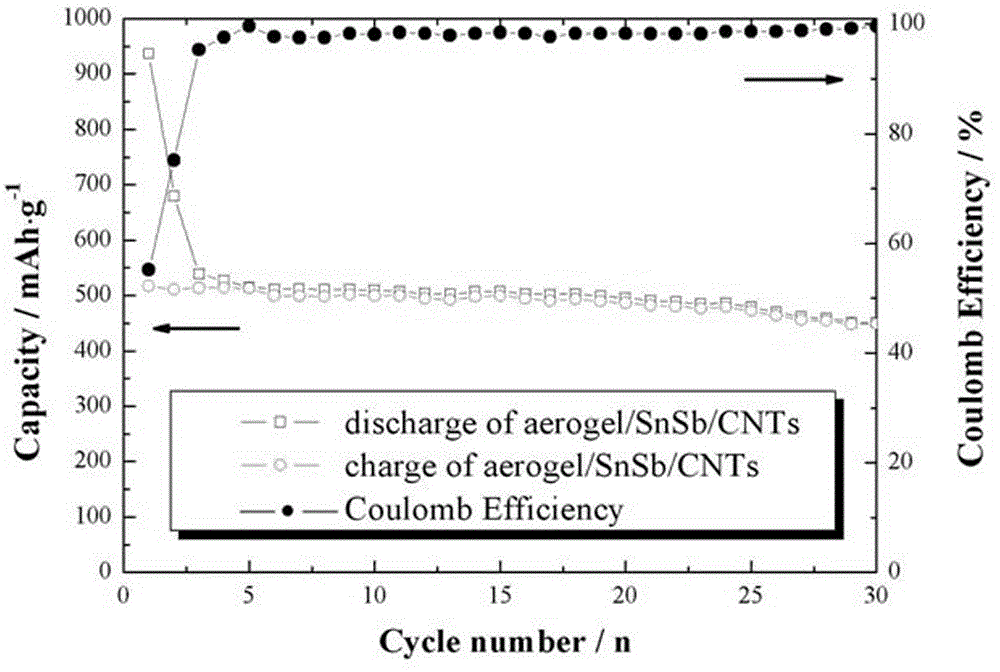

[0050] The constant current charge and discharge test of the composite negative electrode material described in this example shows that the electrochemical performance remains basically unchanged, and after 30 cycles, the reversible capacity can be maintained at 472mAh g -1 .

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com