Advanced control method for direct-current boost converter system

A technology of DC boost and control method, which is applied in the direction of converting DC power input to DC power output, control/regulation systems, instruments, etc., which can solve the problem that it is difficult for closed-loop systems to achieve fast and high-precision voltage output performance, and it is difficult to quickly track Given voltage, voltage input changes and other issues, to improve the anti-disturbance performance and tracking performance, good application value, and the effect of suppressing disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the invention, and detailed implementation methods and specific implementation processes are given, but the protection scope of the present invention is not limited to the following examples .

[0026] step one:

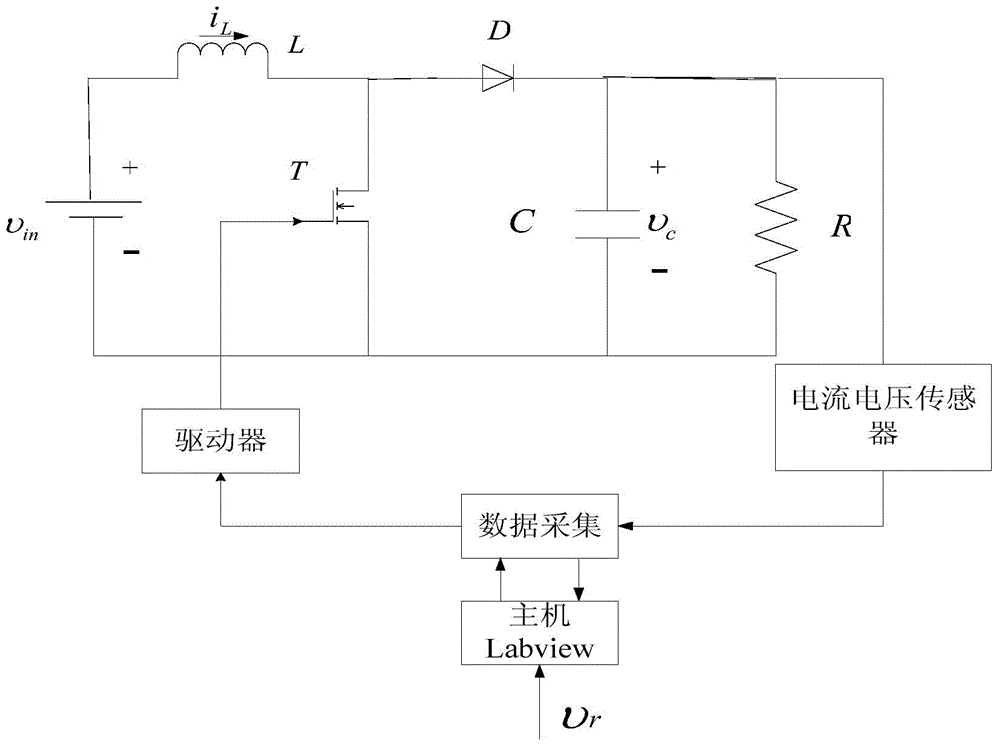

[0027] Such as figure 1 Show the structure diagram, establish a basic structure diagram of a DC boost converter, υ in Is the input voltage, L is the input inductance, i L Is the inductor current, D is the diode, T is the switch tube, C is the output capacitance, R is the load resistance, u is the control input of the switch tube T, that is, the controller output, υ c To output voltage, use current and voltage sensors to collect output voltage and inductor current signals, feed them back to DAQ board, perform control algorithm calculations in the host computer LabVIEW to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com