A device for drying and recycling pig blood protein powder

A recovery device and protein powder technology are applied in the field of pig blood reuse processing devices, which can solve the problems of an undisclosed preparation device, the production performance needs to be improved, and the production process is not environmentally friendly enough to achieve improved immunity, low ash content, and dehydration. The effect of removing the smell of blood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

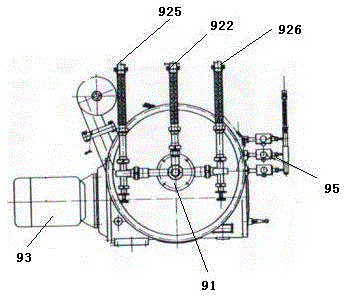

[0055] Such as Figure 1-Figure 7 As shown, the disc separator 9 includes a body, a drum 91 is arranged inside the body, an inlet and outlet device 92 is arranged on the top of the body, and the inlet and outlet device 92 includes a raw material inlet pipe 922, a heavy phase outlet pipe 925 and a light phase outlet arranged in parallel. Pipe 926, raw material inlet pipe 922, heavy phase outlet pipe 925 and light phase outlet pipe 926 communicate with the drum 91, and the side of the body is provided with a slagging part 93 and a waste water outlet 94 communicating with the drum 91, and the waste water outlet 94 is located at the slagging Below the part 93, the side of the body is provided with a cleaning water inlet 95, and a PLC device is provided in the slag discharge part 93;

[0056] The inlet and outlet device 92 includes an inlet and outlet seat 921 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com