Preparation and application of perovskite catalyst with three-dimensional ordered macroporous structure

A technology with three-dimensional order and pore structure, applied in the direction of physical/chemical process catalysts, structural parts, metal/metal oxide/metal hydroxide catalysts, etc., can solve a large number of cracks or micro-cracks in the 3DOM skeleton and damage the structural integrity , small size and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

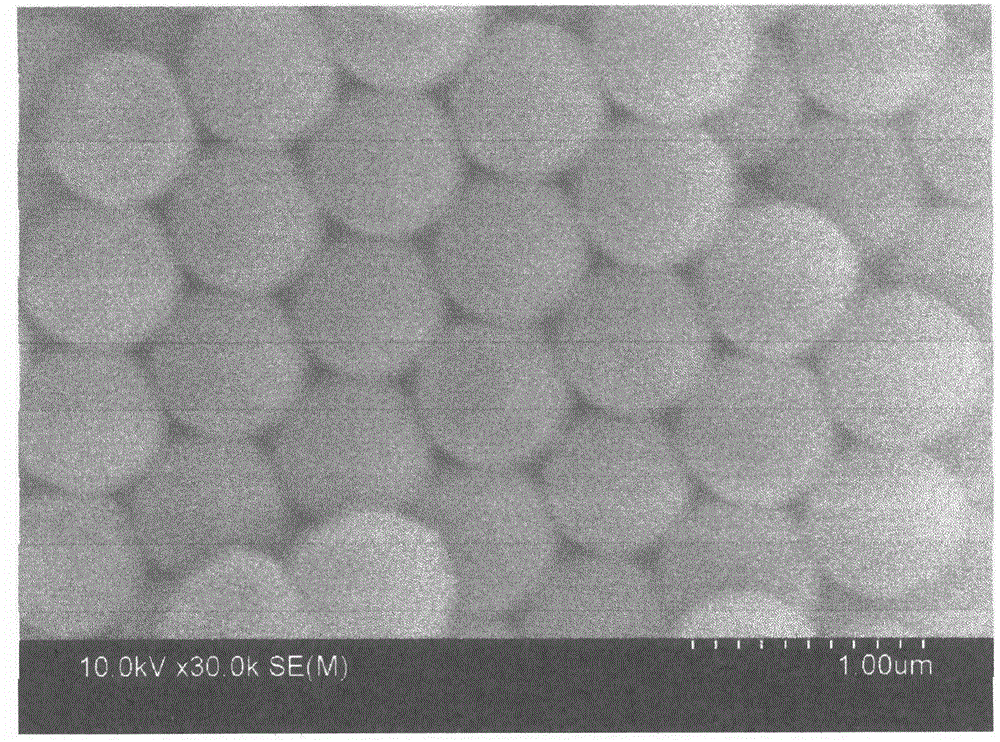

[0020] The colloidal crystal template method is used to prepare polystyrene colloidal crystals. First, measure 10 mL of styrene and place it in a separatory funnel. In order to remove the polymerization inhibitor contained in styrene, use the same volume of NaOH (0.1mol / L) and Wash with distilled water four times until the pH of styrene is neutral. Secondly, inject 100mL of distilled water and washed styrene (St) monomer into a 250mL four-necked round bottom flask equipped with a stirrer, reflux condenser, thermometer and gas tube, and blow nitrogen for 15 minutes to remove oxygen in the system Then, after the temperature was raised to 70°C, 0.004 g of potassium persulfate (KPS) was added as an initiator to initiate the polymerization reaction. After the polymerization reaction was reacted at a constant temperature under the protection of nitrogen for 10 hours, the polystyrene mother liquor was poured out, and the agglomerated objects were filtered to obtain a homogeneous emuls...

Embodiment 2

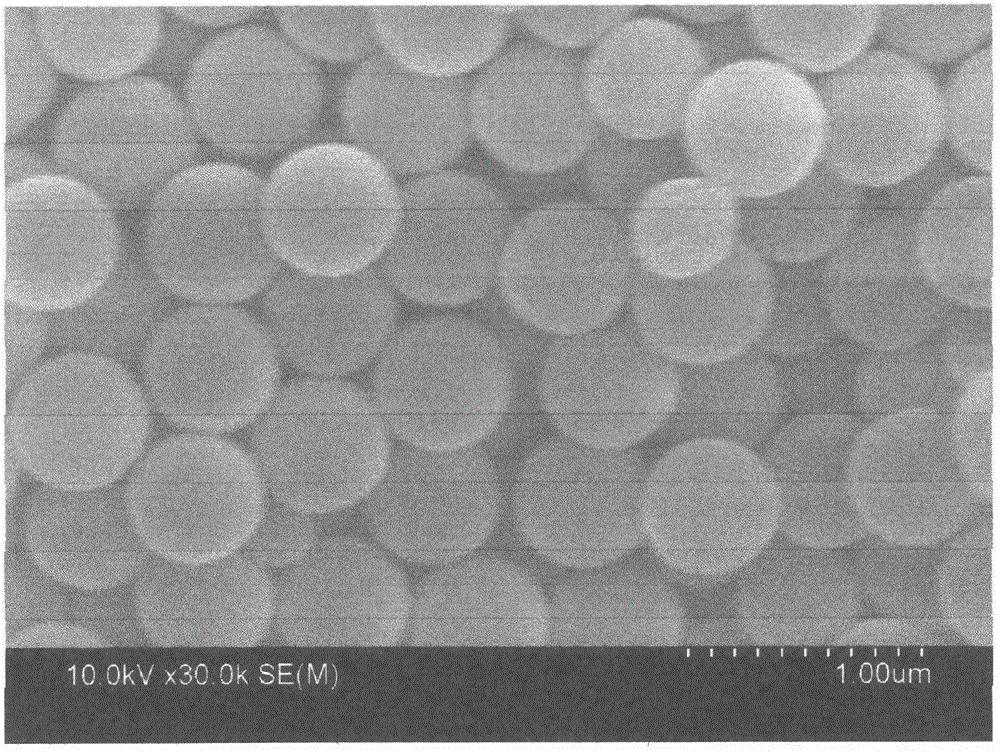

[0022] The colloidal crystal template method is used to prepare polystyrene colloidal crystals. First, measure 10 mL of styrene and place it in a separatory funnel. In order to remove the polymerization inhibitor contained in styrene, use the same volume of NaOH (0.1mol / L) and Wash with distilled water four times until the pH of styrene is neutral. Secondly, inject 100mL of distilled water and washed styrene (St) monomer into a 250mL four-necked round bottom flask equipped with a stirrer, reflux condenser, thermometer and gas tube, and blow nitrogen for 15 minutes to remove oxygen in the system Then, after the temperature was raised to 70°C, 0.007g of potassium persulfate (KPS) was added as an initiator to initiate the polymerization reaction. After the polymerization reaction was reacted at a constant temperature under the protection of nitrogen for 10 hours, the polystyrene mother liquor was poured out, and the agglomerated objects were filtered to obtain a homogeneous emulsi...

Embodiment 3

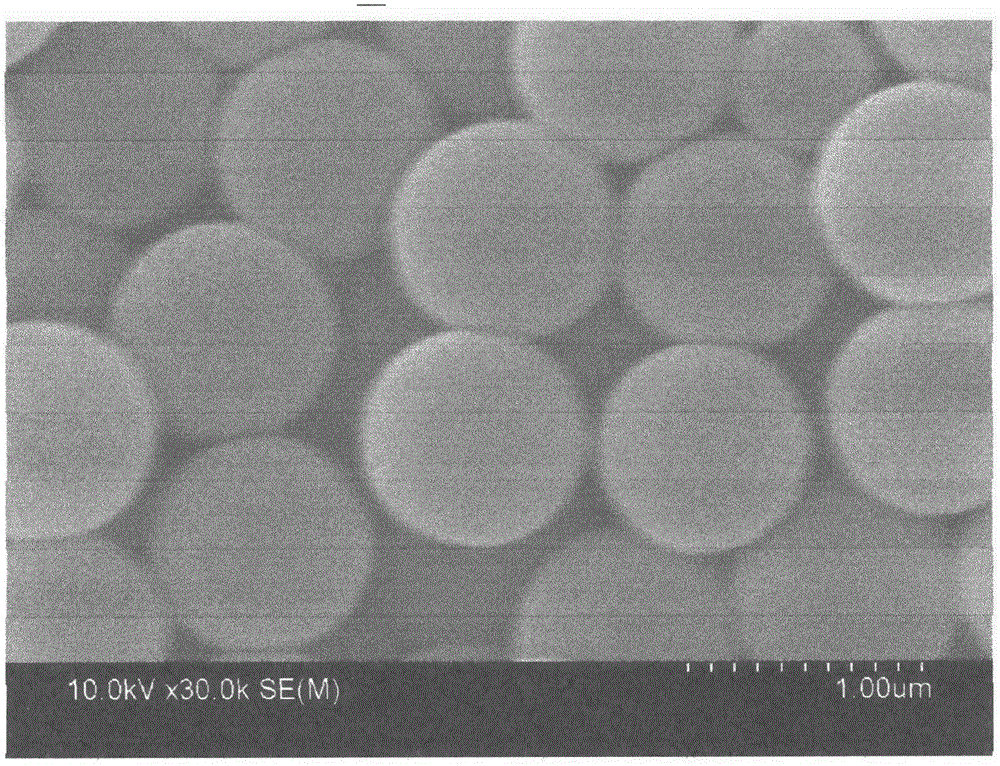

[0024] The colloidal crystal template method is used to prepare polystyrene colloidal crystals. First, measure 10 mL of styrene and place it in a separatory funnel. In order to remove the polymerization inhibitor contained in styrene, use the same volume of NaOH (0.1mol / L) and Wash with distilled water four times until the pH of styrene is neutral. Secondly, inject 100mL of distilled water and washed styrene (St) monomer into a 250mL four-necked round bottom flask equipped with a stirrer, reflux condenser, thermometer and gas tube, and blow nitrogen for 15 minutes to remove oxygen in the system Then, after the temperature was raised to 70°C, 0.01 g of potassium persulfate (KPS) was added as an initiator to initiate the polymerization reaction. After the polymerization reaction was reacted at a constant temperature under the protection of nitrogen for 10 hours, the polystyrene mother liquor was poured out, and the agglomerated objects were filtered to obtain a homogeneous emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com