Micro-abrasive material water-jet cutting head apparatus

A technology of cutting head and material water, which is applied in the direction of abrasive feeding device, abrasive, grinding/polishing equipment, etc., can solve the problems of uncontrollable abrasive flow, uneven abrasive suction, and failure of abrasive conveying system, so as to prevent abrasive The effect of failure of the conveying system, controllable feeding flow rate and high feeding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

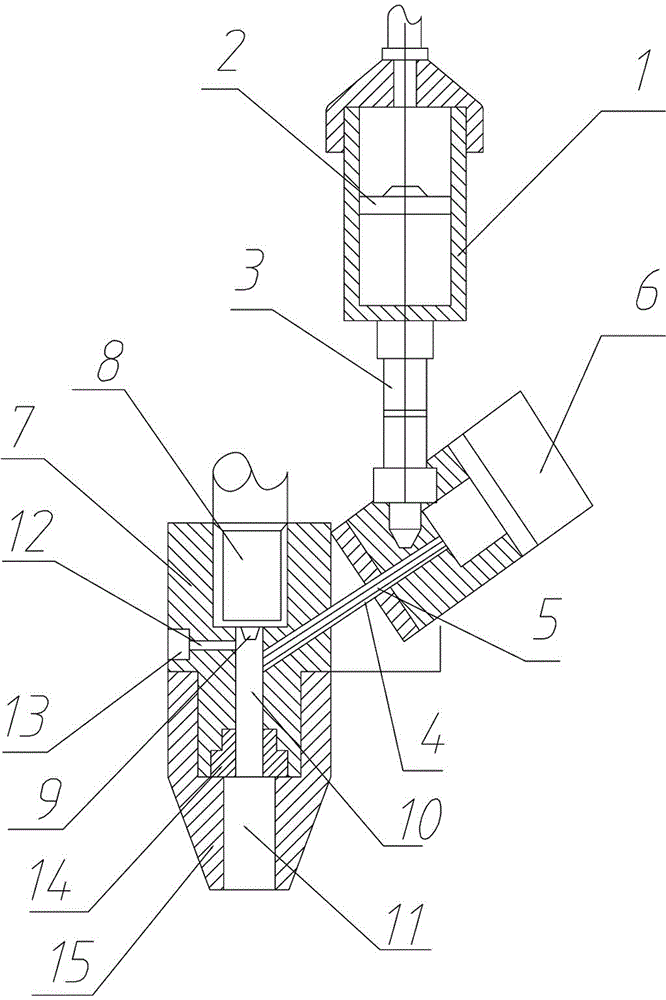

[0011] The microabrasive water jet cutting head device of the present invention includes a storage tank 1, a mixing chamber 10 and a spray head 7. A piston 2 is arranged in the storage tank 1, and the piston 2 divides the storage tank into a compressed air chamber and a slurry abrasive A feeding hose 3 is connected to the lower end of the storage tank 1, and the feeding hose 3 is connected to the mixing chamber 10 through the screw pump casing 4. A feeding screw 5 connected to the stepping motor 6 is arranged in the screw pump casing 4. The mixing chamber 10 is set in the spray head 7, the upper end of the spray head 7 is provided with a high-pressure water chamber 8, the lower end of the high-pressure water chamber 8 is connected to the mixing chamber 10 through the water nozzle 9, and the lower end of the mixing chamber 10 is provided with a mixture nozzle 11 . A drainage channel 12 is opened on the mixing chamber 10, and a one-way valve 13 is arranged on the drainage channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com