Spherical calcium citrate, and preparation method and application thereof

A technology of calcium citrate and citrate, which is applied in the direction of carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problem of no spherical calcium citrate, etc., and achieve the purpose of expanding the scope of application and expanding the application field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides the preparation method of the above-mentioned spherical calcium citrate, water-soluble calcium salt and water-soluble citrate are mixed with water to obtain a mixed aqueous solution of calcium salt and citrate, and the mixed aqueous solution of calcium salt and citrate is mixed at 40 Heating and stirring at -99°C for 2min-30min, separating the obtained solid-liquid mixture into solid-liquid, washing and drying to obtain spherical calcium citrate; wherein, in the mixed aqueous solution of calcium salt and citrate, by molar ratio, calcium ion: lemon Acid radical > 2.5:2; preferably, calcium ion: citrate = 2.8-8:2; more preferably, calcium ion: citrate = 2.8-3.2:2.

[0029] In the present invention, calcium citrate can be separated out in the calcium salt-citrate solution above 40 degrees, because calcium salt and citrate are all dissolved in water, so the temperature generally cannot exceed the boiling point of water; if the temperature ...

Embodiment 1

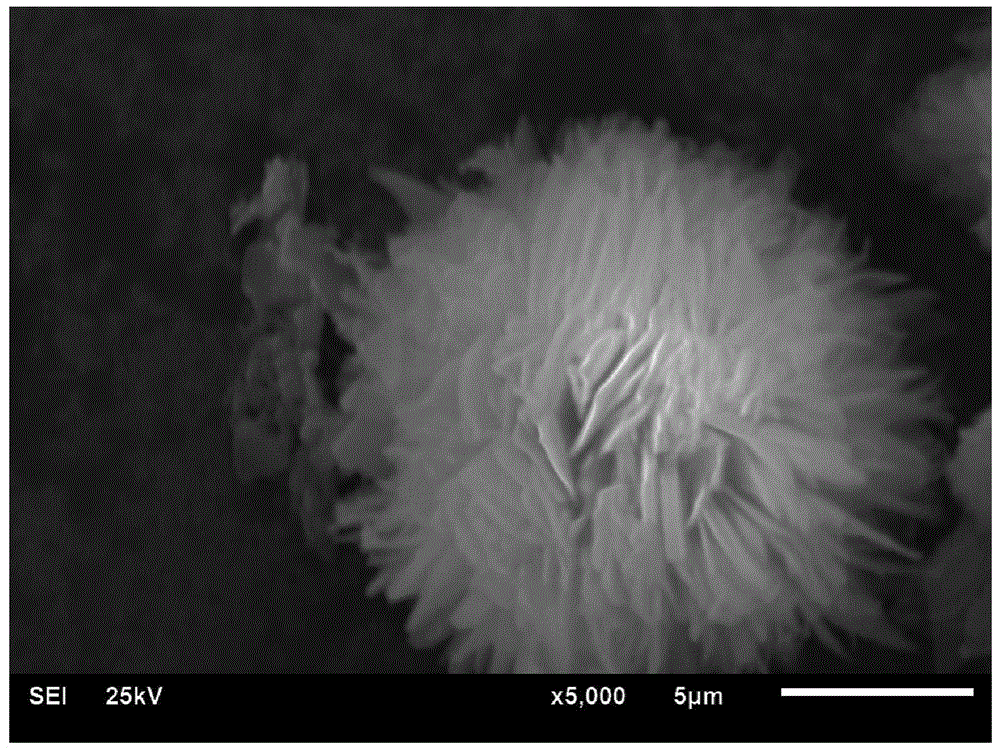

[0038] Weigh 0.8670 g of CaCl respectively 2 , 1.4854 g Na 3 C 6 h 5 o 7 2H 2 O, add 20ml water to dissolve in the beaker; Na 3 C 6 h 5 o 7 2H 2 O solution was added to CaCl 2 , stir evenly; put the beaker with the mixed solution into the water bath, the water bath temperature is 75 degrees Celsius, and the stirring speed is set to 20r / min; take out the beaker after 2 minutes, add distilled water to the beaker and cool to room temperature (due to the temperature from 75 degrees Celsius The natural cooling time is relatively slow, which is too long compared to the 2min of the water bath. In order to make the reaction end quickly, cold water is added to cool down quickly); filtration, solid-liquid separation, washing of the solid for 3 times and then freeze-drying can obtain self-assembled spherical citric acid Calcium, its SEM image is shown in figure 1 shown; its diameter is 10-20 microns. Its specific surface area is 1.737m2 using the BET method 2 / g. The XRD fi...

Embodiment 2

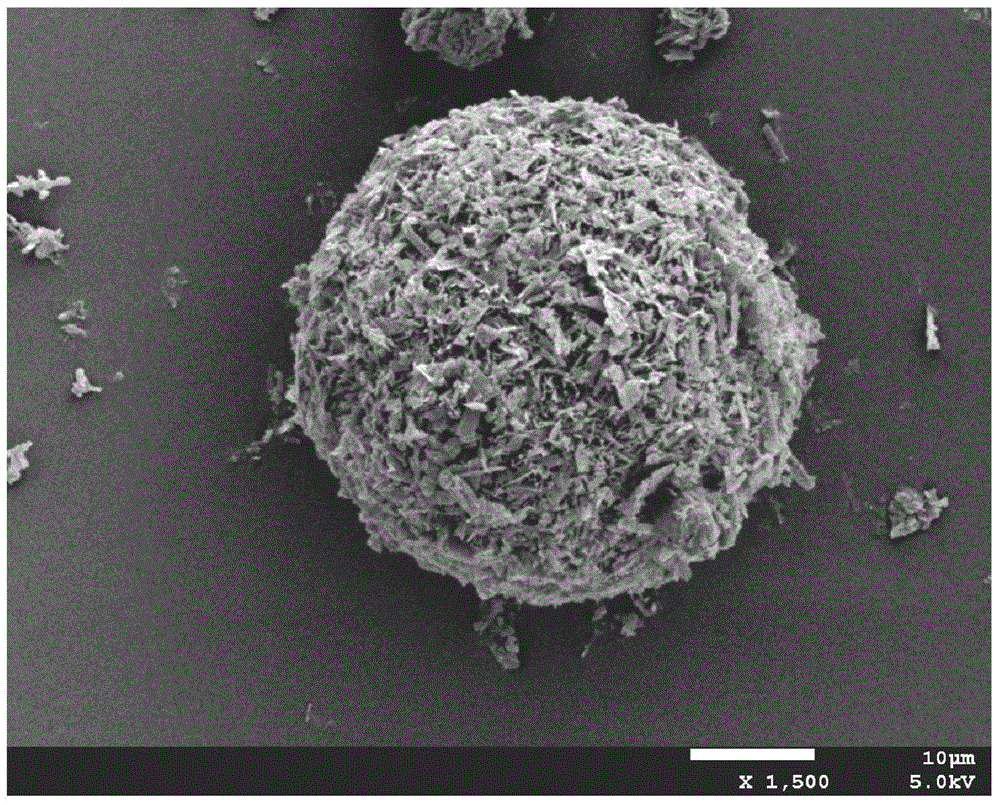

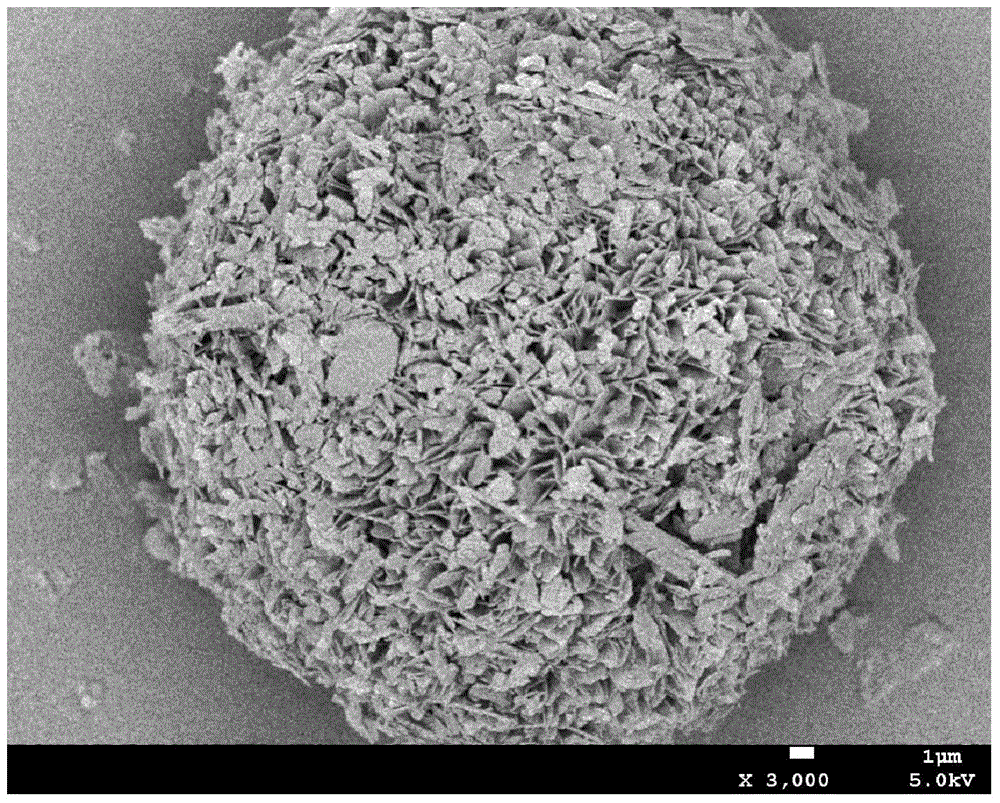

[0040] Weigh 0.8670 g of CaCl respectively 2 , 1.4854 g Na 3 C 6 h 5 o 7 2H 2 O, add 20ml water to dissolve in the beaker; Na 3 C 6 h 5 o 7 2H 2 O solution was added to CaCl 2 solution, stir evenly; put the beaker containing the mixed solution into a water bath, the temperature of the water bath is 75 degrees Celsius, and the stirring speed is set to 20r / min; take out the beaker after 5 minutes, add distilled water to the beaker and cool to room temperature; filter, solidify Liquid separation, the solid was washed 3 times and then freeze-dried to obtain self-assembled spherical calcium citrate, whose diameter was 10-20 microns as shown by its SEM image. Its specific surface area is 50.824m2 using the BET method 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com