Methyl methacrylate resin with excellent thermal stability

A technology of methyl methacrylate and thermal stability, which is applied in the field of thermoplastic polymers, can solve the problems of multiple volatiles, low thermal decomposition temperature, and easy thermal decomposition, etc., to achieve improved thermal stability, simple preparation method, and improved The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

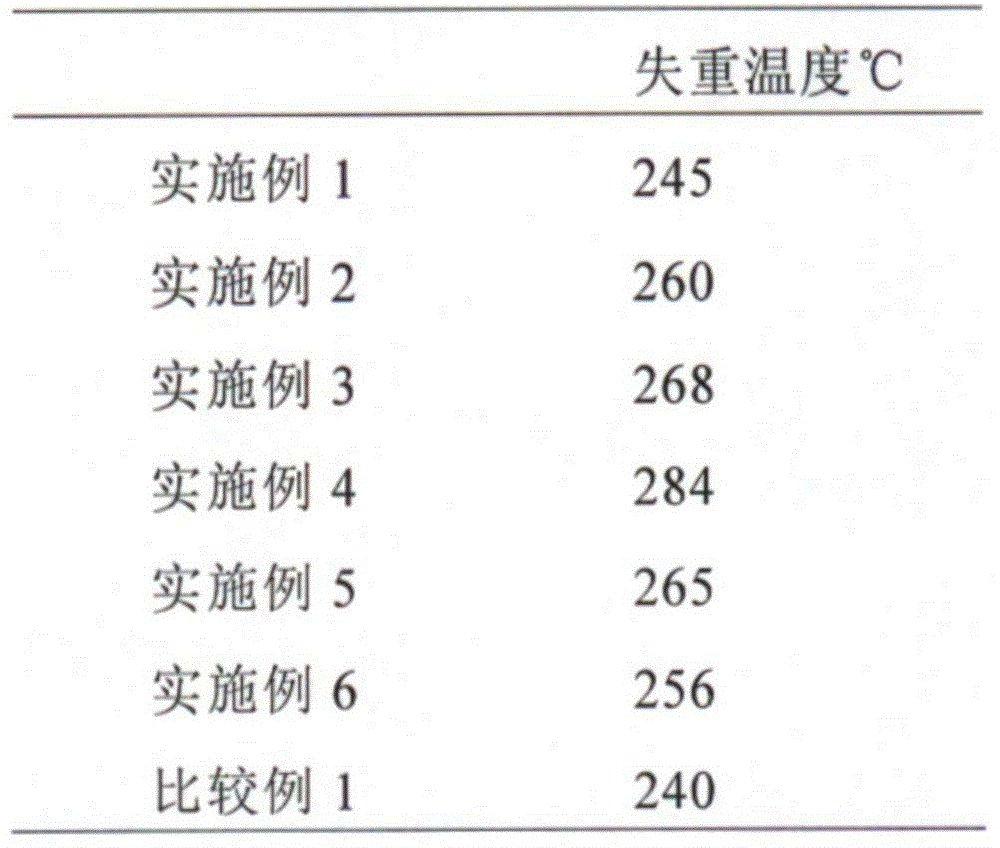

Embodiment 1

[0022] A kind of methyl methacrylate resin with excellent thermal stability, the method may further comprise the steps:

[0023] (1) Prepare materials according to the following components and parts by weight:

[0024] PMMA 100;

[0025] Antioxidant B900 0.5;

[0026] Phosphine tribromide 0.1;

[0027] (2) After stirring and mixing PMMA resin, antioxidant, and phosphine halide derivatives in a high-speed mixer, they are sent into a twin-screw extruder through a metering device, and the temperature of the twin-screw extruder is controlled at 180-230°C. Under the transportation, shearing and mixing of the screw, the materials are melted and compounded, and finally through the steps of extrusion, drawing, cooling and pelletizing, the methyl methacrylate resin with excellent thermal stability is obtained.

Embodiment 2

[0029] A kind of methyl methacrylate resin with excellent thermal stability, the method may further comprise the steps:

[0030] (1) Prepare materials according to the following components and parts by weight:

[0031] PMMA resin 100;

[0032] Antioxidant B900 0.3;

[0033] Methyltriphenylphosphine bromide 0.5;

[0034] (2) preparation method is the same as embodiment 1

Embodiment 3

[0036] A kind of methyl methacrylate resin with excellent thermal stability, the method may further comprise the steps:

[0037] (1) Prepare materials according to the following components and parts by weight:

[0038] PMMA resin 100;

[0039] Antioxidant B900 0.3;

[0040] Methyltriphenylphosphine bromide 1.0;

[0041] (2) preparation method is the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com