a hydraulic oil

A technology of hydraulic oil and oily extreme pressure agent, which is applied in the field of hydraulic oil, can solve the problems of poor flame resistance and achieve good shear resistance, corrosion prevention, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

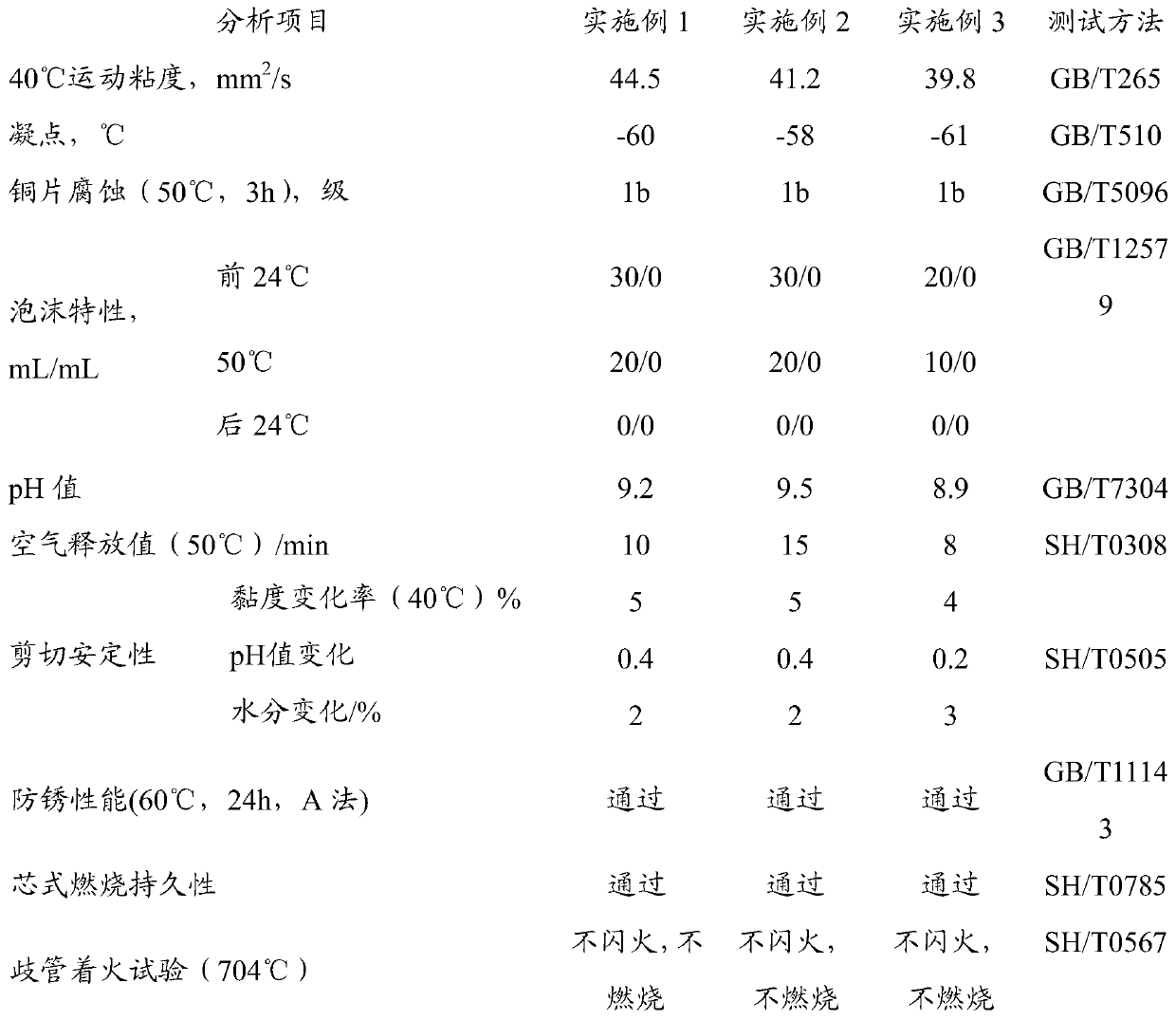

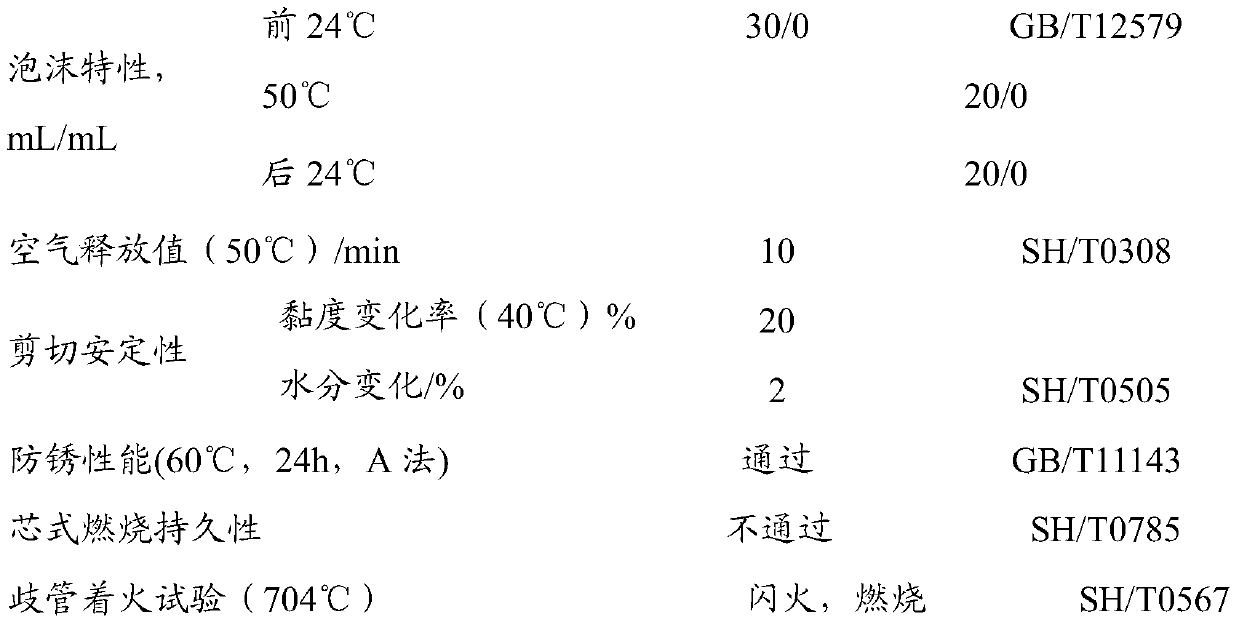

Examples

preparation example Construction

[0028] In the present invention, the preparation method of the hydraulic oil preferably comprises the following steps:

[0029] a) mixing a glycol compound and a tackifier to obtain a first mixture;

[0030] b) mixing the first mixture obtained in step a) with water, antirust agent, metal deactivator, oily extreme pressure agent, and pH regulator to obtain a second mixture;

[0031] c) mixing the second mixture obtained in step b) with the antifoaming agent to obtain hydraulic oil.

[0032] In the present invention, the glycol compound and the tackifier are mixed to obtain the first mixture. In the present invention, it is preferred to raise the temperature of the diol compound to 70°C-90°C, and then mix it with the tackifier; more preferably, the temperature of the glycol compound is raised to 75°C-85°C, and then mixed with the tackifier Mixing; most preferably, the diol compound is heated to 80°C, and then mixed with the tackifier. In the present invention, it is preferre...

Embodiment 1

[0042] Step a), send 35kg of ethylene glycol into the blending kettle with a gear pump, evacuate, stir, heat, and raise the temperature to 80°C; add 18kg of tackifier KE-1 to the heated ethylene glycol, and stir until it increases. The adhesive is completely dissolved to obtain the first mixture;

[0043] Step b), adding 40.8kg water to the first mixture obtained in step a), then adding 2.45kg barium dinonylnaphthalenesulfonate, 2.2kg lauric acid, 0.25kg ethylenediaminetetraacetic acid, 1.2kg ethanolamine, temperature control At 70°C, dissolve to obtain the second mixture;

[0044] Step c), adding 0.1kg PE-6100 antifoam agent to the second mixture obtained in step b), dissolving to obtain the third mixture, taking out 10kg of the third mixture, adding 0.03% clay of all the third mixture weight wherein Stir the filter aid, and carry out circulating filtration, so that the filter aid forms a filter cake in the filter machine, and then circulate and filter the remaining 90kg of ...

Embodiment 2

[0046] Step a), 45kg of ethylene glycol is sent into the blending kettle with a gear pump, evacuated, stirred, heated, and the temperature is raised to 80°C; 13kg of tackifier polyethylene glycol is added to the heated ethylene glycol, and stirred until it increases The adhesive is completely dissolved to obtain the first mixture;

[0047] Step b) Add 33.9 kg of water to the first mixture obtained in step a), then add 5 kg of dodecenylsuccinic acid, 0.5 kg of oily extreme pressure agent T406, and 0.5 kg of thiadiazole derivatives of T561 , 2kg triethanolamine, temperature controlled at 70°C, dissolved to obtain the second mixture;

[0048] Step c) Add 0.1 kg of simethicone antifoam agent mother liquor to the second mixture obtained in step b), and after dissolving, a third mixture is obtained; 10 kg of the third mixture is taken out, and 0.03% diatomaceous earth of all the third mixture weight is added Stir the filter aid, and carry out circulating filtration, so that the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| Viscosity change rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com