Method for modifying thermal power station by storing energy through fused salt and device of method

A thermal power station and molten salt technology, applied in the field of solar thermal power generation and energy storage, can solve the problems of urban heating pipe network that consume a lot of manpower, material and financial resources, achieve rational use of energy, solve environmental problems, and solve the problem of excessive steam transmission distance big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

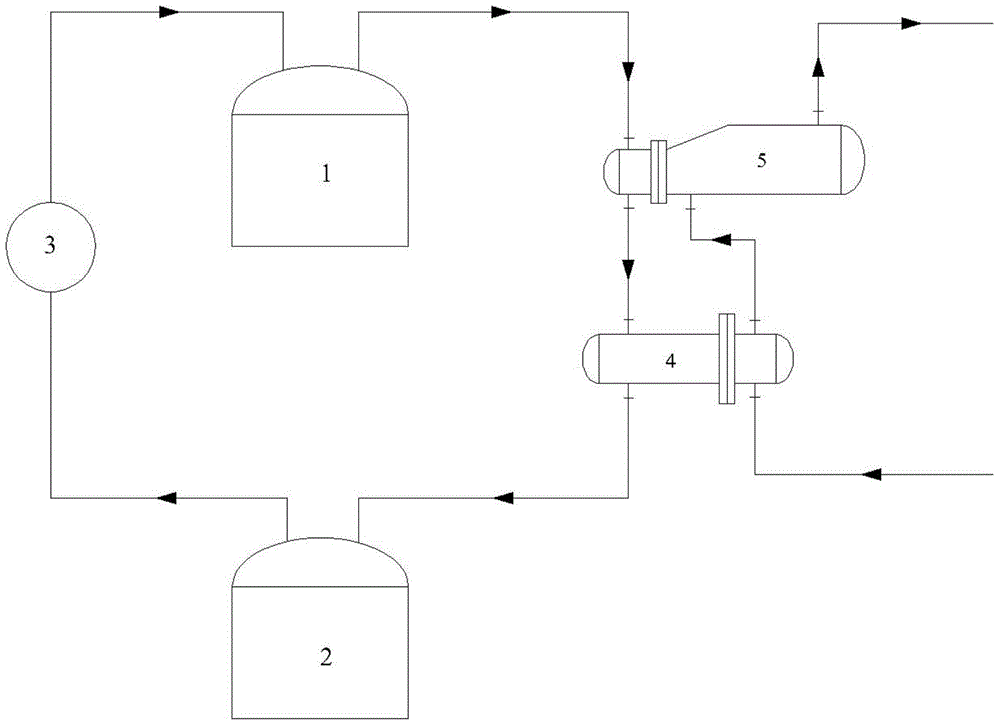

[0016] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] like figure 1 Shown is the device used in the method of using molten salt energy storage for thermal power station transformation, including molten salt heat storage system and steam generation system. The molten salt heat storage system is composed of a high-temperature molten salt tank 1, a low-temperature molten salt tank 2, and an electrically heated molten salt tank (furnace) 3; the steam generation system is composed of a preheater 4 and a steam generator 5.

[0018] figure 1 Among them, the electric heating molten salt tank / furnace is set between the high and low temperature molten salt tanks to heat the low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com