A mems thermal flow sensor and its manufacturing method

A thermal flow sensor technology, applied in the field of sensing, can solve the problems of thermal flow sensor being easily polluted, anti-vibration and heat insulation incompatibility, etc., to ensure heat insulation and anti-vibration performance, and ensure measurement Accuracy and sensitivity, effects of preventing contamination and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

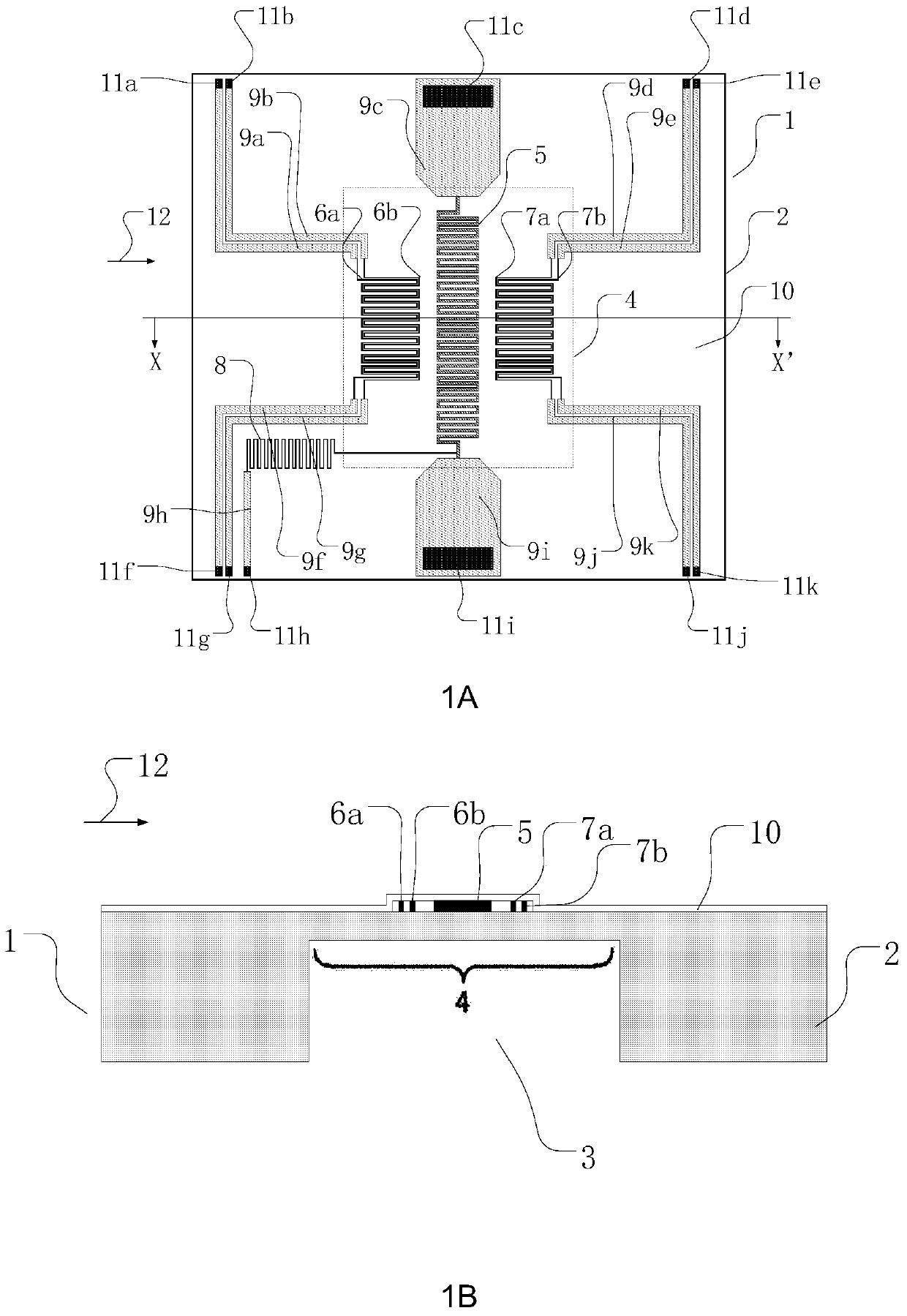

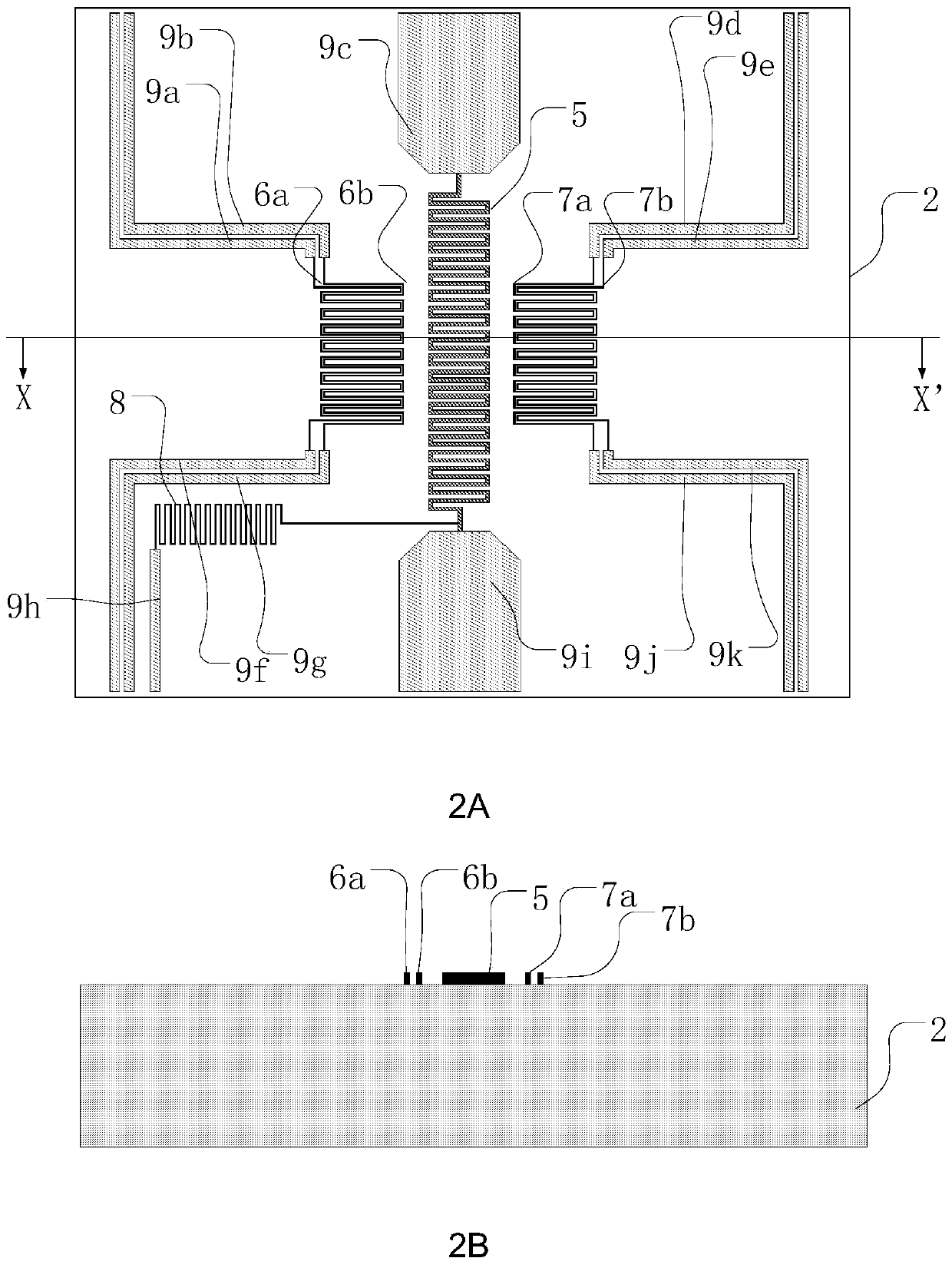

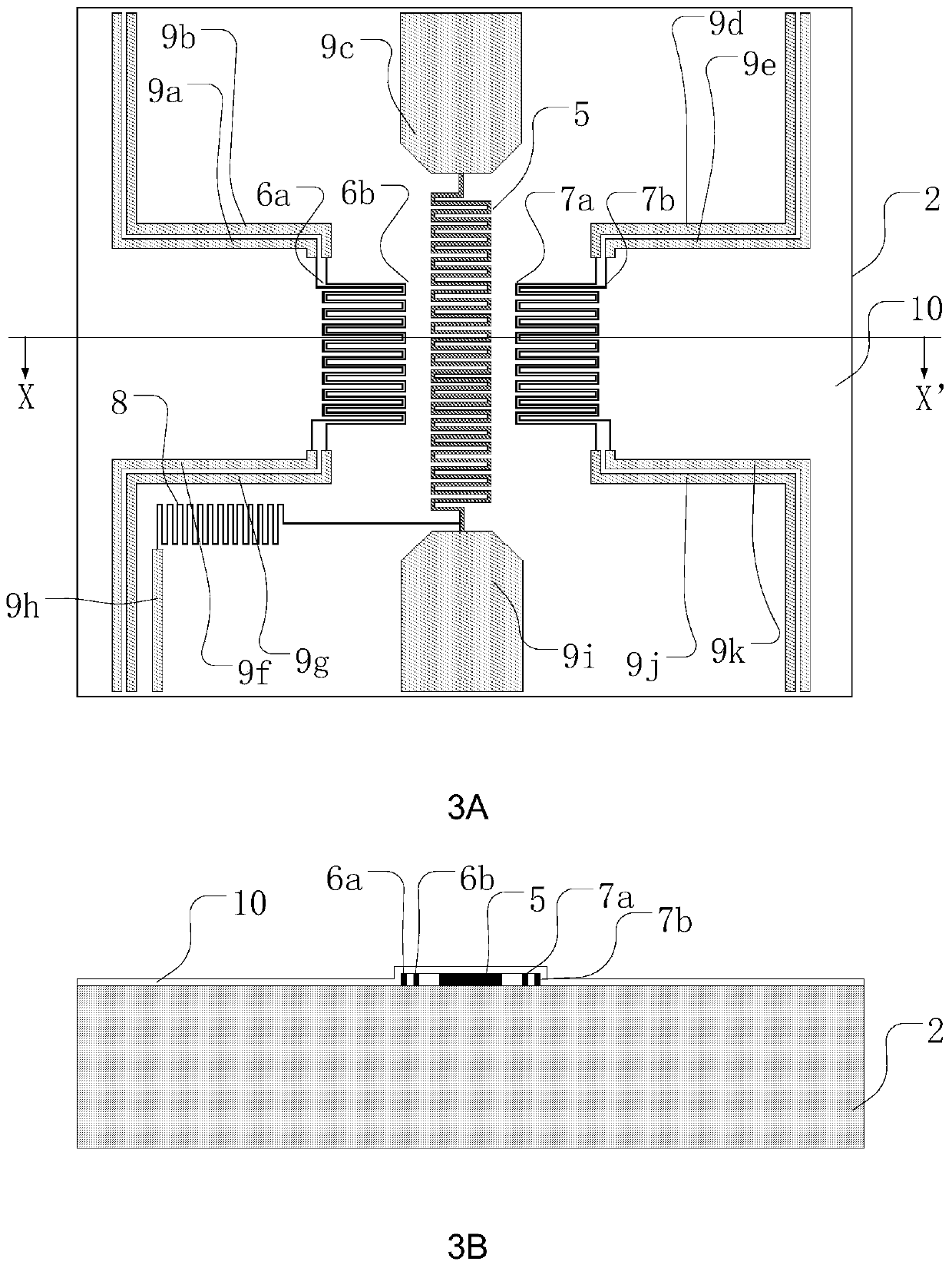

[0032] figure 1 It is a structural schematic diagram of MEMS thermal flow sensor of the present invention, 1A is its top view, and 1B is its edge view. figure 1 Sectional view of line X-X' of A.

[0033] MEMS thermal flow sensor 1, its structure includes a substrate 2, a cavity 3 is arranged at the bottom of the substrate 2, the substrate above the cavity 3 forms a thin film layer 4; the upper surface of the thin film layer 4 has a heating resistor 5, and the heating Resistor 5 is perpendicular to the direction of fluid movement, heating and controlling heating resistor 5 to make its temperature higher than that of fluid 12; both sides of heating resistor 5 are symmetrically arranged with a first group of thermistors along the direction of fluid movement and the second group of thermistor bodies, wherein the first group of thermistor bodies includes the first thermistor body 6a and the second thermistor body 6b, and the second group of thermistor bodies includes the third the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com