A method for the preparation of glutathione-imprinted sensors by magnetron-induced self-assembly and rapid film formation

A glutathione and self-assembly technology, applied in the field of analysis and detection, to achieve the effects of good conductivity, improved selectivity and enhanced sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] a) Electrode pretreatment: magnetic glassy carbon electrode (Φ=5mm) through 0.05μm A1 2 o 3 After the suspension was polished, it was ultrasonically cleaned with absolute ethanol and deionized water for 2 min respectively.

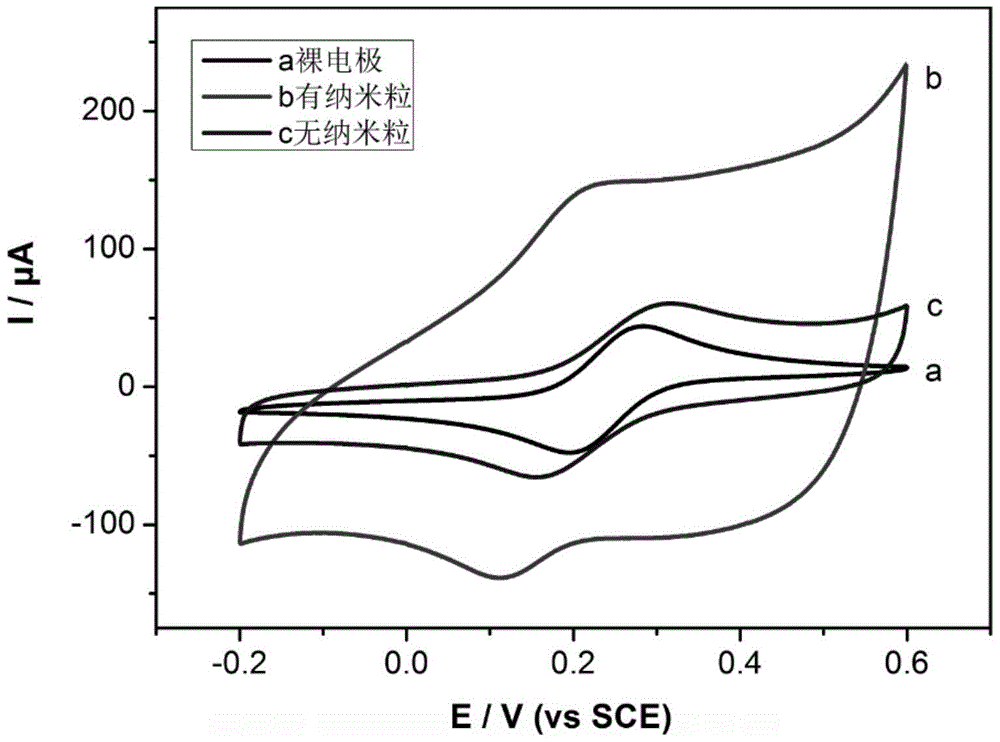

[0051] b) Fe 3 o 4 Preparation of @PANI-rGO composite nanoparticles: In a 100mL three-necked bottle, take 6.5mg mL -1 Graphene oxide (GO) 3mL was dissolved in 40mL deionized water and ultrasonicated for 1h. Then add the prepared 0.5g Fe 3 o 4 @PANI composite nanoparticles, pre-assemble reaction at 80°C for 1h, add 0.3mL reducing agent hydrazine hydrate, and stir at constant temperature for 10h. Magnetic separation, washing to neutrality, and vacuum drying for 24 hours to obtain Fe 3 o 4 @PANI-rGO tri-primitive composite nanoparticles.

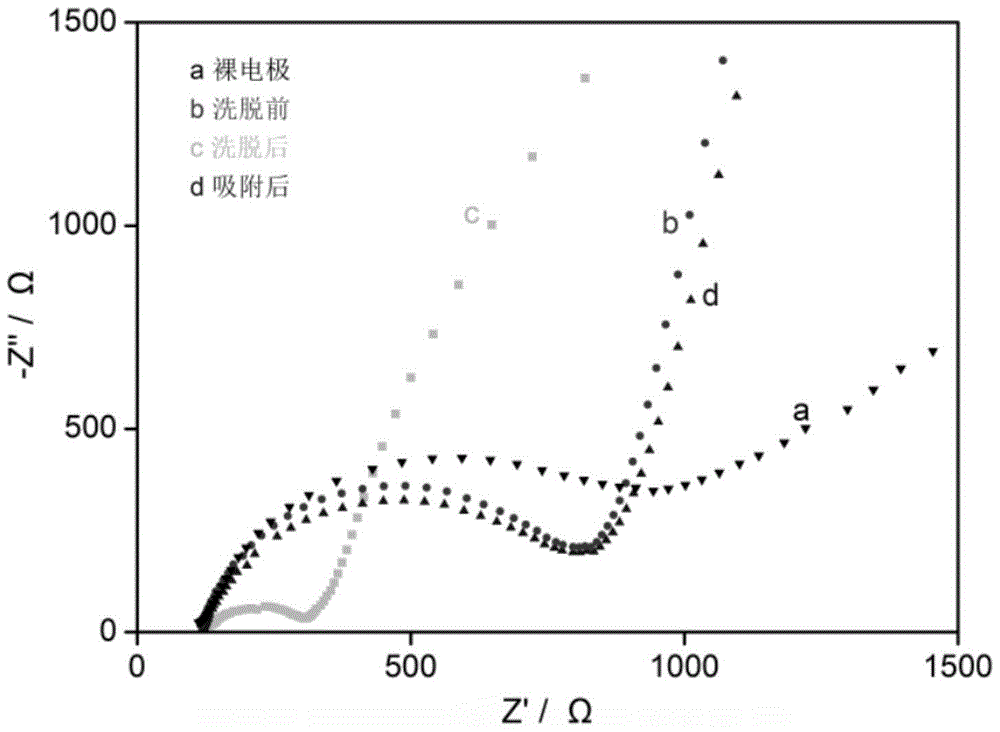

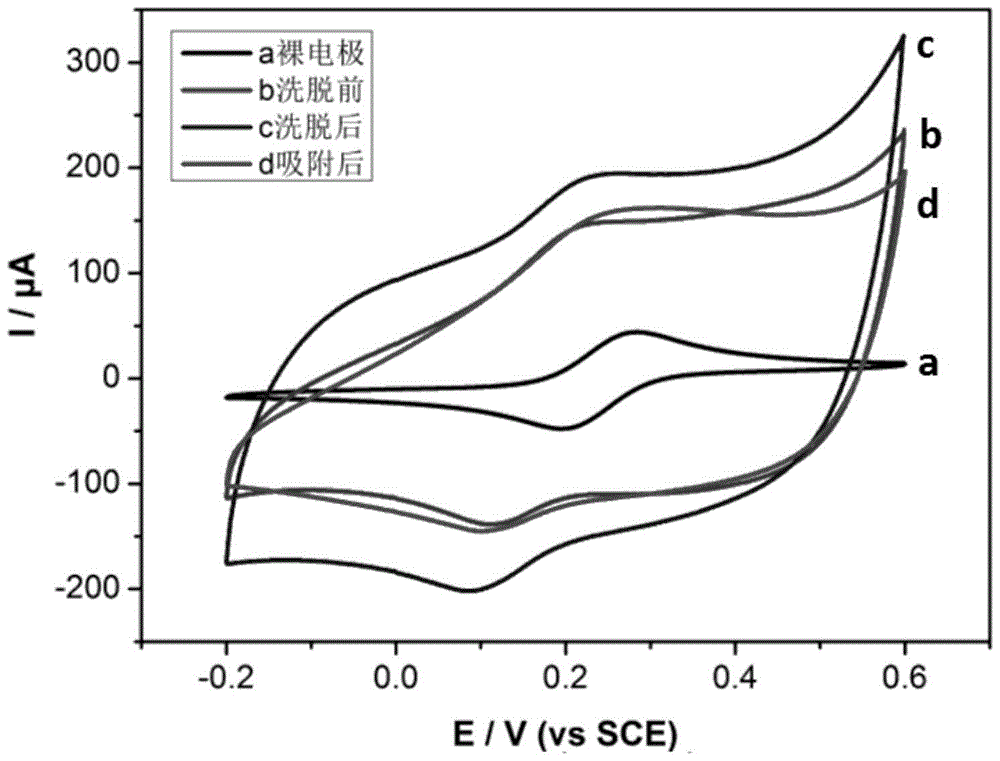

[0052] c) Pre-assembly of composite nanoparticles and imprinted layer hydrogen-bonded complex: preparation containing 2.5mmol L -1 GSH (glutathione), 0.3mg L -1 Fe 3 o 4 @PANI-rGO composite nanoparticles...

Embodiment 2

[0057] a) Electrode pretreatment: magnetic glassy carbon electrode (Φ=5mm) through 0.05μm A1 2 o 3 After the suspension was polished, it was ultrasonically cleaned with absolute ethanol and deionized water for 2 min respectively.

[0058] b) Fe 3 o 4 Preparation of @PANI-rGO composite nanoparticles: in a 100mL three-necked bottle, 6.5mg mL -1 Graphene oxide (GO) 6mL was dissolved in 40mL deionized water and ultrasonicated for 1h. Then add the prepared 0.5g Fe 3 o 4 @PANI composite nanoparticles, pre-assemble reaction at 80°C for 1h, add 0.2mL reducing agent hydrazine hydrate, and stir at constant temperature for 10h. Magnetic separation, washing to neutrality, and vacuum drying for 24 hours to obtain Fe 3 o 4 @PANI-rGO tri-primitive composite nanoparticles.

[0059] c) Pre-assembly of composite nanoparticles and imprinted layer hydrogen-bonded complex: preparation containing 2.5mmol L -1 GSH (glutathione), 0.3mg L -1 Fe 3 o 4 @PANI-rGO composite nanoparticles, 75m...

Embodiment 3

[0064] a) Electrode pretreatment: magnetic glassy carbon electrode (Φ=5mm) through 0.05μm A1 2 o 3 After the suspension was polished, it was ultrasonically cleaned with absolute ethanol and deionized water for 2 min respectively.

[0065] b) Fe 3 o 4 Preparation of @PANI-rGO composite nanoparticles: In a 100mL three-necked bottle, take 6.5mg mL -1 Graphene oxide (GO) 5mL was dissolved in 40mL deionized water, and sonicated for 1h. Then add the prepared 0.5g Fe 3 o 4 @PANI composite nanoparticles, pre-assemble reaction at 80°C for 1h, add 0.3mL reducing agent hydrazine hydrate, and stir at constant temperature for 10h. Magnetic separation, washing to neutrality, and vacuum drying for 24 hours to obtain Fe 3 o 4 @PANI-rGO tri-primitive composite nanoparticles.

[0066] c) Pre-assembly of composite nanoparticles and imprinted layer hydrogen-bonded complex: preparation containing 2.5mmol L -1 GSH (glutathione), 0.3mg L -1 Fe 3 o 4 @PANI-rGO composite nanoparticles, 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com