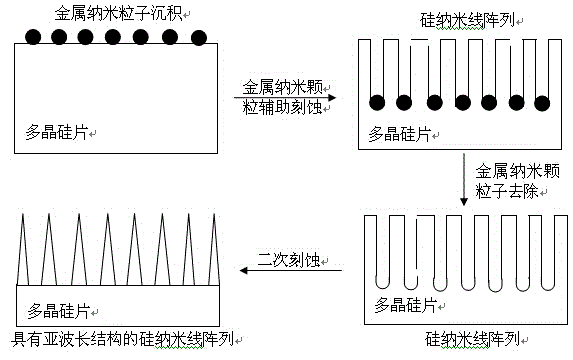

Preparation method of sub-wavelength silicon nanowire array

A silicon nanowire array and sub-wavelength technology, which is applied in the field of nanomaterials, achieves the effects of reducing production costs, great application prospects, and good anti-reflection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the sub-wavelength silicon nanowire array described in this embodiment specifically comprises the following steps:

[0028] (1) Set the size to 156×156mm 2 1. A commercial solar-grade polysilicon wafer with a doping type of p-type, a resistance of 1Ω, and a thickness of 220 μm was ultrasonically cleaned with acetone, toluene, ethanol, and deionized water for 10 minutes;

[0029] (2) put in H 2 SO 4 and H 2 o 2Soak for 1 minute in a solution with a volume ratio of 3:1, then soak for 10 minutes in a hydrofluoric acid solution with a concentration of 10 wt%, take it out and rinse it with a large amount of deionized water for later use;

[0030] (3) Prepare 500ml HF / AgNO 3 Etching solution, HF and AgNO 3 The concentrations are 2.3mol / L and 5mol / L respectively; put the cleaned polysilicon wafer into the etching solution, move it to a dark room and let it stand for 50 minutes to obtain a silicon nanowire array with metal ions;

[0031] (4) Tak...

Embodiment 2

[0034] The preparation method of the sub-wavelength silicon nanowire array described in this embodiment specifically comprises the following steps:

[0035] (1) Set the size to 156×156mm 2 1. A commercial solar-grade polysilicon wafer with a doping type of p-type, a resistance of 2Ω, and a thickness of 210 μm was ultrasonically cleaned with acetone, toluene, ethanol, and deionized water for 10 minutes;

[0036] (2) put in H 2 SO 4 and H 2 o 2 Soak it in a solution with a volume ratio of 3:1 for 10 minutes, then soak it in a hydrofluoric acid solution with a concentration of 0.1wt% for 120 minutes, take it out and wash it with a large amount of deionized water for later use;

[0037] (3) Prepare 500ml HF / H 2 PtCl 6 Etching solution, HF and H 2 PtCl 6 The concentrations are 15mol / L and 5mol / L respectively; put the cleaned polysilicon wafer into the etching solution and let it stand for 5min to obtain a silicon nanowire array with metal ions;

[0038] (4) Take out the si...

Embodiment 3

[0041] The preparation method of the sub-wavelength silicon nanowire array described in this embodiment specifically comprises the following steps:

[0042] (1) Set the size to 156×156mm 2 1. A commercial solar-grade polysilicon wafer with a doping type of p-type, a resistance of 3Ω, and a thickness of 180 μm was ultrasonically cleaned with acetone, toluene, ethanol, and deionized water for 10 minutes;

[0043] (2) put in H 2 SO 4 and H 2 o 2 Soak in a solution with a volume ratio of 3:1 for 2 minutes, then soak in a hydrofluoric acid solution with a concentration of 5wt% for 20 minutes, take it out and wash it with a large amount of deionized water for subsequent use;

[0044] (3) Prepare 500ml HF / KAuCl 4 Etching solution, HF and KAuCl 4 The concentrations are 0.1mol / L and 10mol / L respectively; put the cleaned polysilicon wafer into the etching solution, then move it to the dark room and let it stand for 600min;

[0045] (4) After that, take out the silicon nanowire ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com