2-micron laser device enabling linearly polarized output

A laser and linear polarization technology, applied in the field of 2μm laser devices, can solve problems such as difficult debugging and complex structure, and achieve the effects of reducing difficulty of debugging, reducing space volume, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

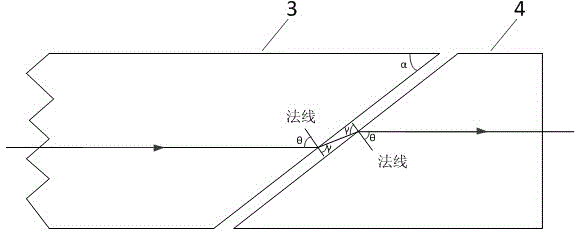

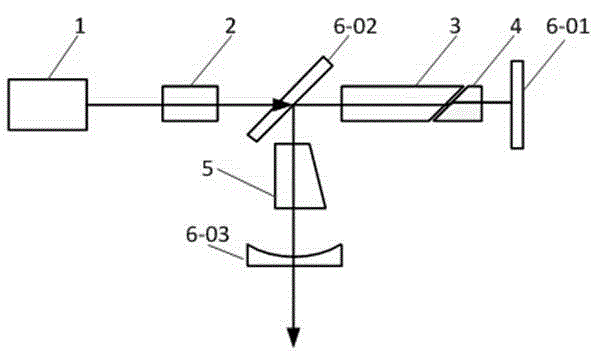

[0020] refer to figure 1 As shown, the 1.9 μm laser pump source 1 in this embodiment selects a Tm:YLF solid-state laser, the output laser wavelength is within the absorption bandwidth of the Ho:YAG laser crystal 3, the maximum output power is 30W, the beam quality factor M2=1.2, the line The width is less than 3nm, and the center wavelength is 1908nm. The optical coupling system 2 used adopts two lenses with focal lengths of 30mm and 50mm respectively. The pump light passes through the coupling system 2 and is focused on the center of the Ho:YAG laser crystal 3. The spot size at the beam waist is 350μm, Ho:YAG laser crystal 3 uses Ho:YAG crystal with Ho ion doping concentration of 0.7 at.%, size is 3mm×3mm×35mm; refer to figure 2 As shown, the enlarged view of Ho:YAG laser crystal 3 and YAG crystal 4 together: the normal line is the normal line of the inclined plane where the Brewster angle cut by the crystal end face is located, and α is the Brewster angle cut by the crystal...

Embodiment 2

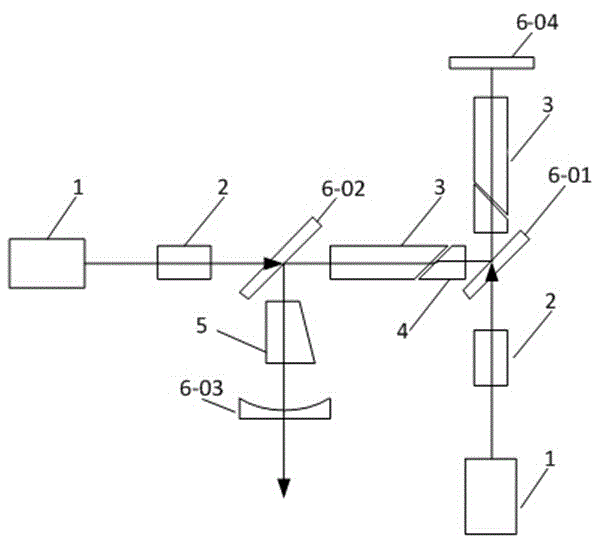

[0022] refer to image 3 As shown in the figure, this embodiment is improved on the basis of the first embodiment, and the main difference with the structure of the first embodiment is: in order to further improve the output power of 2 μm, two Ho:YAG laser crystals 3 are used in series, each Each Ho:YAG laser crystal 3 is pumped by a Tm:YLF laser, and the fourth cavity mirror 6-04 is added, so that the number of cavity mirrors is increased to four, and the curvature radius of the third cavity mirror 6-03 is increased to R= 1000mm, when the total pump power is 60 watts, the output power of the laser reaches 31.5 watts, and the degree of linear polarization is 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com