An inkjet ink composition

An ink composition, inkjet ink technology, applied in the direction of ink, household utensils, applications, etc., can solve the problems of poor throw distance, poor reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] A set of thermal inkjet inks suitable for direct printing on food surfaces was prepared using the formulations shown in Table 1 with increasing levels of sugar (in this case xylitol) from 0 to 5%.

[0167]

[0168]

[0169] Table 1

[0170] Table 2 shows the viscosity measured using a Brookfield DV-II+ viscometer at 60 rpm at 25°C and the surface tension measured for each ink on a KSV Cam 200 optical tensiometer using the pendant drop method.

[0171]

[0172] Table 2

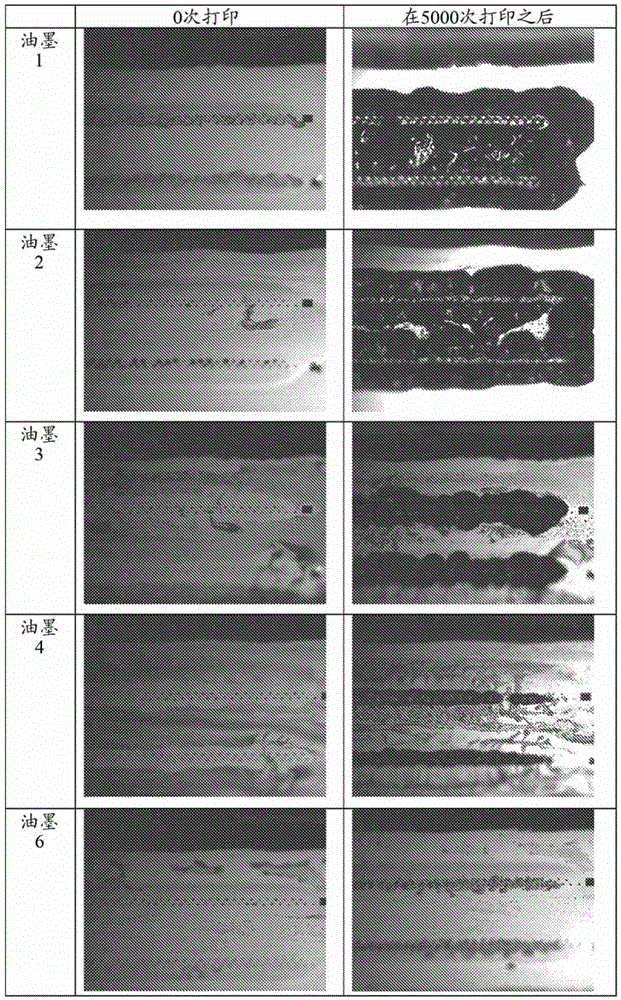

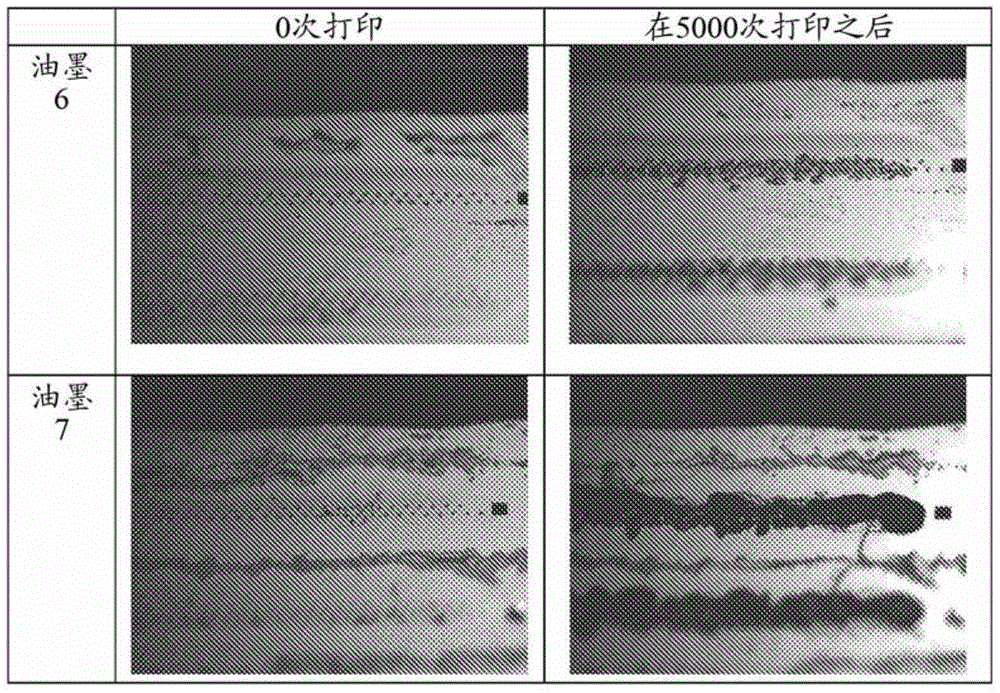

[0173] To evaluate the effect of sugar content on nozzle plate wetting, a Lexmark cartridge was filled with each ink and a standard 6-line alphanumeric code was printed. Images of the nozzle plate were taken before printing started and after 500 prints.

[0174] figure 1 It is shown that in the absence of sugar in the formulation (Ink 1 ), the ink would be seen bleeding out of the nozzle even when not printing, and after 5000 prints, significant nozzle wetting would be seen. With 1% sugar in...

Embodiment 2

[0185] To investigate the effect of sugar inclusion in ink formulations on throw distance, a set of thermal inkjet inks suitable for direct printing onto food surfaces were prepared using the formulations shown in Table 5.

[0186]

[0187] table 5

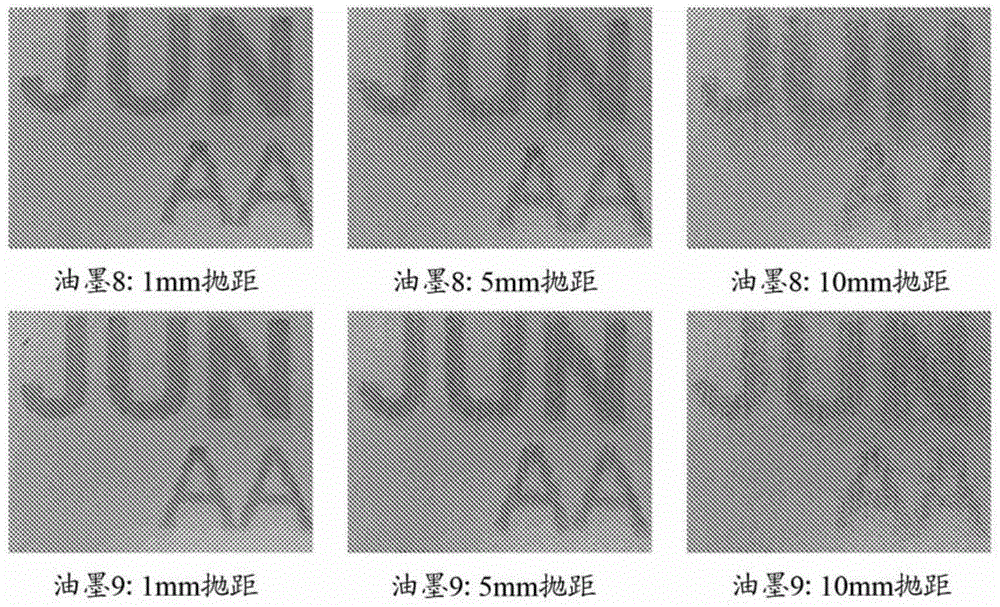

[0188] To evaluate the effect of including sugar (in this case, xylitol) on throw distance, each ink was filled into a Lexmark cartridge and then dropped as the distance between the substrate (in this case, paper) and the nozzle increased. Prints a standard 6-line alphanumeric code. Images were then captured of partially printed codes using a Celestron handheld digital microscope at 40X magnification.

[0189] image 3 The images in Figure 1 show that both inks give good image quality at a throw distance of 1 mm, and as the distance between nozzle and substrate increases, better image quality is achieved with ink 9, where in the formulation Include sugar.

Embodiment 3

[0191] To investigate the effect of including sugar in ink formulations on decap time, a set of thermal inkjet inks suitable for direct printing onto food surfaces were prepared using the formulations shown in Table 6.

[0192]

[0193] Table 6

[0194] To evaluate the effect of including sugar on ink decap performance, each ink was filled into a Lexmark cartridge and then printed with a standard 6-line alphanumeric code. After the cartridge was left open for 2 hours, the same 6-line code was printed again, and the ease of recovery of the printed code quality was checked. Images were then captured of partially printed codes using a Celestron handheld digital microscope at 40X magnification.

[0195] Figure 4 The images in show that the quality of the code printed using the control ink (Ink 10) is quite poor after a period of 2 hours, and the second and third prints do not really recover, indicating that the high print quality is unlikely to recover . When multiple suga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com