Grease composition for formula milk powder as well as preparation method and application of grease composition

A technology for oil composition and milk powder, which is applied in the field of oil deep processing, and can solve the problems of bland skim milk powder, loss of nutritional value of milk powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

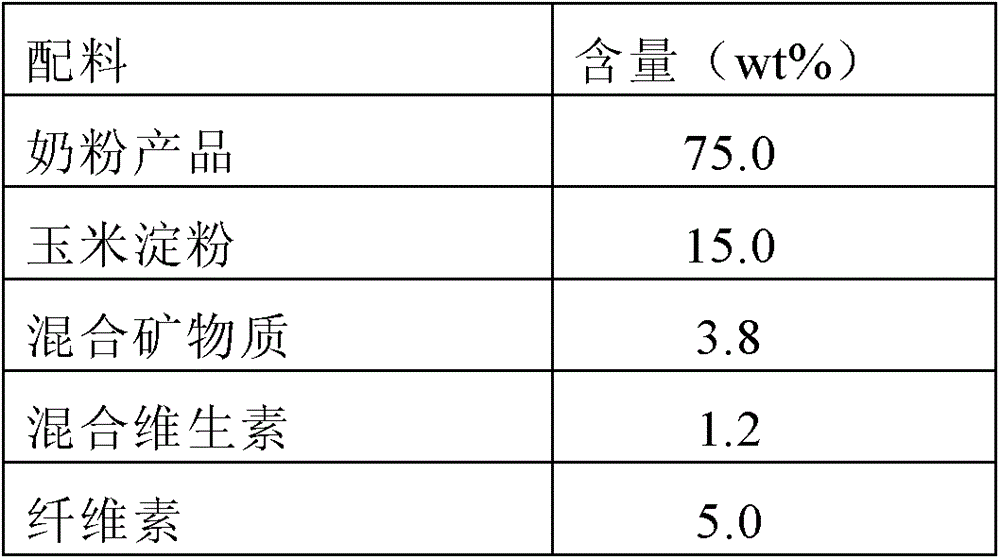

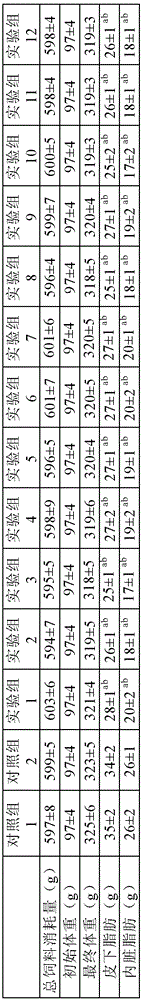

Examples

Embodiment

[0114] Through the following preparation examples and test examples, the technical solution of the present invention will be further explained in detail, but the protection scope of the present invention is not limited to these examples.

[0115] According to the method of GB / T17376-2008, the fatty acid compositions of the following oil compositions were determined. According to the AOCS Ce5b-89 method, the triglyceride content of each of the following oil compositions was measured by HPLC.

preparation example 1

[0117] Calculated by the weight of each raw material oil, 5 parts of medium-carbon chain fatty acid triglycerides (wherein the mass ratio of caprylic acid:capric acid is 1:1), 35 parts of sunflower oil and 60 parts of rapeseed oil were mixed, and the Stir for 10 minutes to make it fully mixed evenly, so as to obtain the oil composition 1. Wherein, relative to the total weight of all fatty acids in the obtained oil composition 1, the content of medium carbon chain fatty acids is 5wt%, the content of long carbon chain saturated fatty acids is 9.24wt%, n-6 series polyunsaturated fatty acids The weight ratio to n-3 series polyunsaturated fatty acids is 5.2:1.

preparation example 2

[0119] Calculated by the weight of each raw material oil, 25 parts of medium-carbon chain fatty acid triglycerides (wherein the mass ratio of caprylic acid: capric acid is 2:8), 71 parts of soybean oil and 4 parts of perilla oil are mixed, and at room temperature Stir for 5 minutes to make it fully mixed, so as to obtain the oil composition 2. Wherein, relative to the total weight of all fatty acids in the obtained oil composition 2, the content of medium-carbon chain fatty acids is 25wt%, the content of long-carbon chain saturated fatty acids is 12.52wt%, n-6 series polyunsaturated fatty acids The weight ratio to n-3 series polyunsaturated fatty acids is 4.7:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com