Method for preparing high-purity chlorogenic acid from jerusalem artichoke leaves

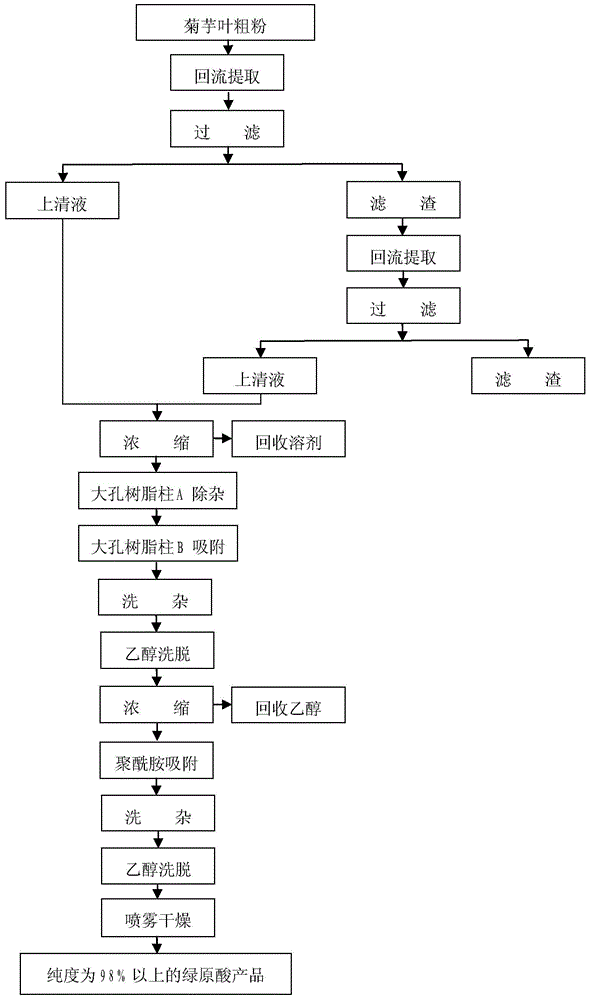

A chlorogenic acid and high-purity technology is applied in the field of preparing high-purity chlorogenic acid, which can solve the problems of low research depth and achieve the effects of continuous and simple operation, efficient separation and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

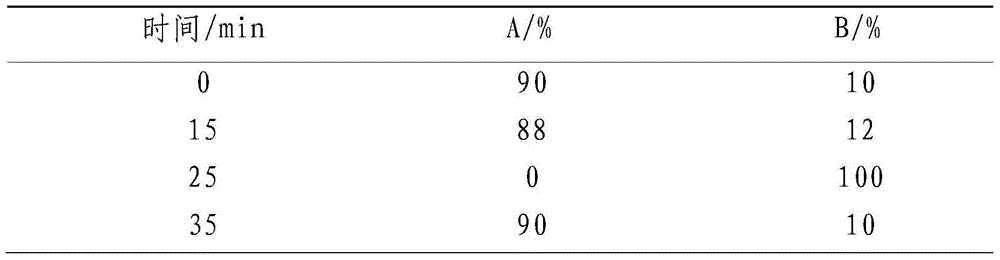

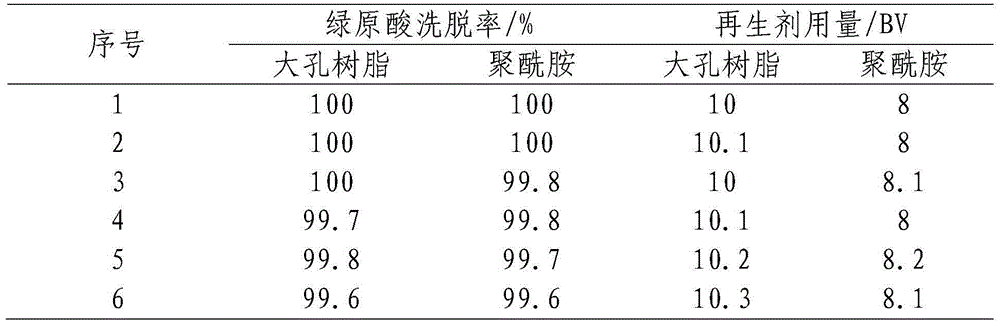

[0028] Take 150g of Jerusalem artichoke leaf meal and put it into an extractor, add 750mL of 20% methanol aqueous solution, heat and reflux at 100°C for extraction twice, each time for 1h. Filter and combine the extracts. Concentrate the extract under reduced pressure to 10% of the original volume fraction, first pass through the D101 macroporous resin column at a flow rate of 5BV / h to remove impurities such as flavonoids, tannins, sugars, and the effluent directly at a flow rate of 5BV / h Put on the ADS-17 macroporous resin column, after the dynamic adsorption is saturated, wash the ADS-17 macroporous resin column with deionized water at a flow rate of 3BV / h until the effluent is colorless, and then use 100% ethanol Elute at a flow rate of 5BV / h, collect the ethanol eluate, concentrate under reduced pressure to a paste, and then dissolve the extract in water according to the ratio of material to liquid 1:5 (g / mL). The aqueous solution is applied to the polyamide column at a f...

Embodiment 2

[0030] Put 600g of Jerusalem artichoke leaf coarse powder into the extractor, add 3500mL methanol aqueous solution with a volume fraction of 40%, and heat and reflux at 80°C for extraction twice, each time for 2h. Filter and combine the extracts. Concentrate the extract under reduced pressure to 10% of the original volume fraction, first pass through the AB-8 macroporous resin column at a flow rate of 4BV / h to remove impurities such as flavonoids, tannins, sugars, and the effluent directly at 4BV / h The flow rate of the S-8 macroporous resin column is passed through the S-8 macroporous resin column. After the dynamic adsorption is saturated, the S-8 macroporous resin column is rinsed with deionized water at a flow rate of 5BV / h until the effluent is colorless, and then the volume fraction is 80%. The ethanol was eluted at a flow rate of 8BV / h, the ethanol eluate was collected, concentrated under reduced pressure to a paste, and then the extract and water were dissolved in water...

Embodiment 3

[0032] Put 1500g of Jerusalem artichoke leaf coarse powder into the extractor, add 15000mL methanol aqueous solution with a volume fraction of 60%, and heat and reflux at 70°C for extraction twice, each time for 3h. Filter and combine the extracts. Concentrate the extract under reduced pressure to 10% of the original volume fraction, first pass through the D101 macroporous resin column at a flow rate of 2BV / h to remove flavonoids, tannins, sugars and other impurities, and the effluent directly at a flow rate of 3BV / h Pass through the X-5 macroporous resin column, after the dynamic adsorption is saturated, wash the X-5 macroporous resin column with deionized water at a flow rate of 8BV / h until the effluent is colorless, and then use 60% ethanol Elute at a flow rate of 7BV / h, collect the ethanol eluate, concentrate under reduced pressure to a paste, and then dissolve the extract in water according to the ratio of material to liquid 1:5 (g / mL). The aqueous solution is applied to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com