Anti-corrosion wood floor

A wood floor and anti-corrosion paint technology, applied in anti-corrosion coatings, floors, buildings, etc., can solve the problems of rotting in less than 5-10 years, shortening the life of solid wood floors, attracting wood pillar insects and termites, etc. It achieves the effect of superior anti-warping function, prolonging the service life and improving the surface brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

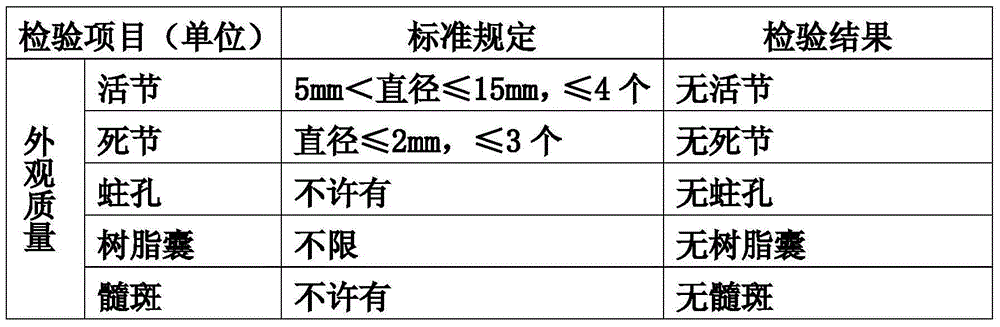

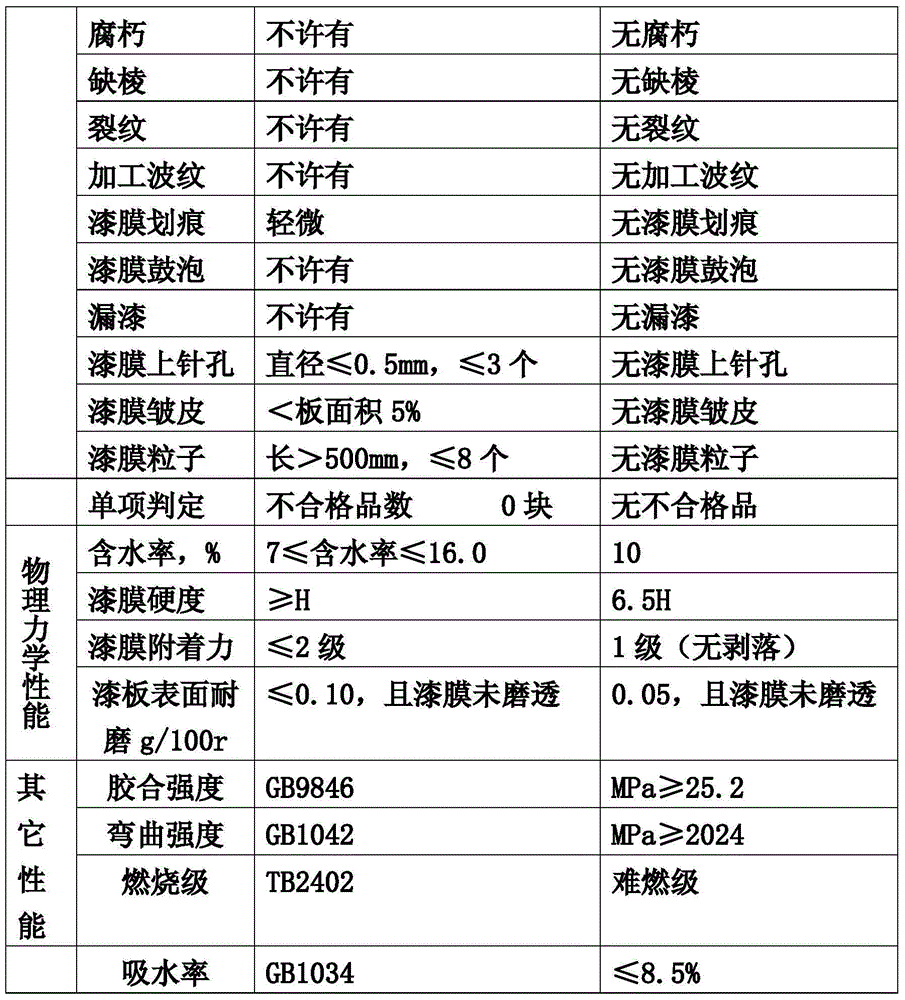

[0018] Example 1: An anticorrosive wood floor. The surface of the wooden floor includes a water-based putty, an anticorrosive paint, and a primer from top to bottom. The water-based putty and primer are all conventional paints in this field. All paints can be purchased directly from the market, so I won’t repeat them here; the anti-corrosion paint includes 20 parts by weight of methyl methacrylate, 20 parts of hydroxy acrylic resin, 15 parts of butyl acetate, and ethylene dichloride. 30 parts of alcohol monoethyl ether, 20 parts of limonene, 5 parts of phthalic anhydride, 0.5 parts of defoaming agent, 0.5 parts of leveling agent, 0.5 parts of wetting agent, 10 parts of mica powder, 15 parts of fillers and 2 parts of pigments. The leveling agent can adopt polyacrylate copolymer and fluorocarbon modified polyacrylate components; the defoamer can adopt a special polyurethane defoamer, the main component is modified silicone; The agent adopts polyether modified dimethylsiloxane cop...

Embodiment 2

[0022] Example 2: An anticorrosive wooden floor, the surface of the wooden floor includes a water-based putty, an anticorrosive paint and a primer from top to bottom; the anticorrosive paint includes 24 parts by weight of methyl methacrylate, hydroxyl Acrylic resin 18 parts, butyl acetate 18 parts, ethylene glycol monoethyl ether 25 parts, limonene 15 parts, phthalic anhydride 8 parts, antifoaming agent 0.5 parts, leveling agent 0.5 parts, wetting agent 0.5 parts, mica powder 12 parts, 12 parts filler and 2 parts pigment.

[0023] The preparation method of the above anticorrosive paint includes the following steps;

[0024] a. Add methyl methacrylate, hydroxy acrylic resin and butyl acetate into the reaction kettle and stir at 250 rpm. During stirring, the temperature is raised to 130°C, then ethylene glycol monoethyl ether and limonene are added, and the temperature is continued to rise. To 230℃, keep for 30 minutes; get A product;

[0025] b. Cool product A to 100°C, add phthalic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com