Optimization method of calcified sodium alginate immobilization enzyme

A technology of sodium alginate and optimization method, which is applied in directions such as being fixed on/in an organic carrier, can solve the problems of polluted reaction system, unstable combination of sodium alginate and divalent cations, and unrecyclable enzymes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

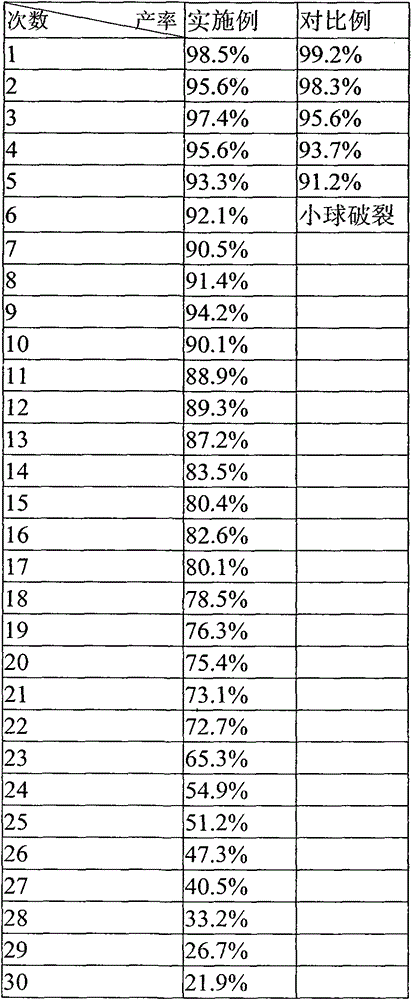

[0016] The reaction selected in this example is the hydrolysis reaction of p-nitrophenol butyrate catalyzed by standardized ester hydrolase. The reaction has the advantages of rapid response, sensitivity, high yield, etc., and can quickly detect the optimization effect of the method of the present invention.

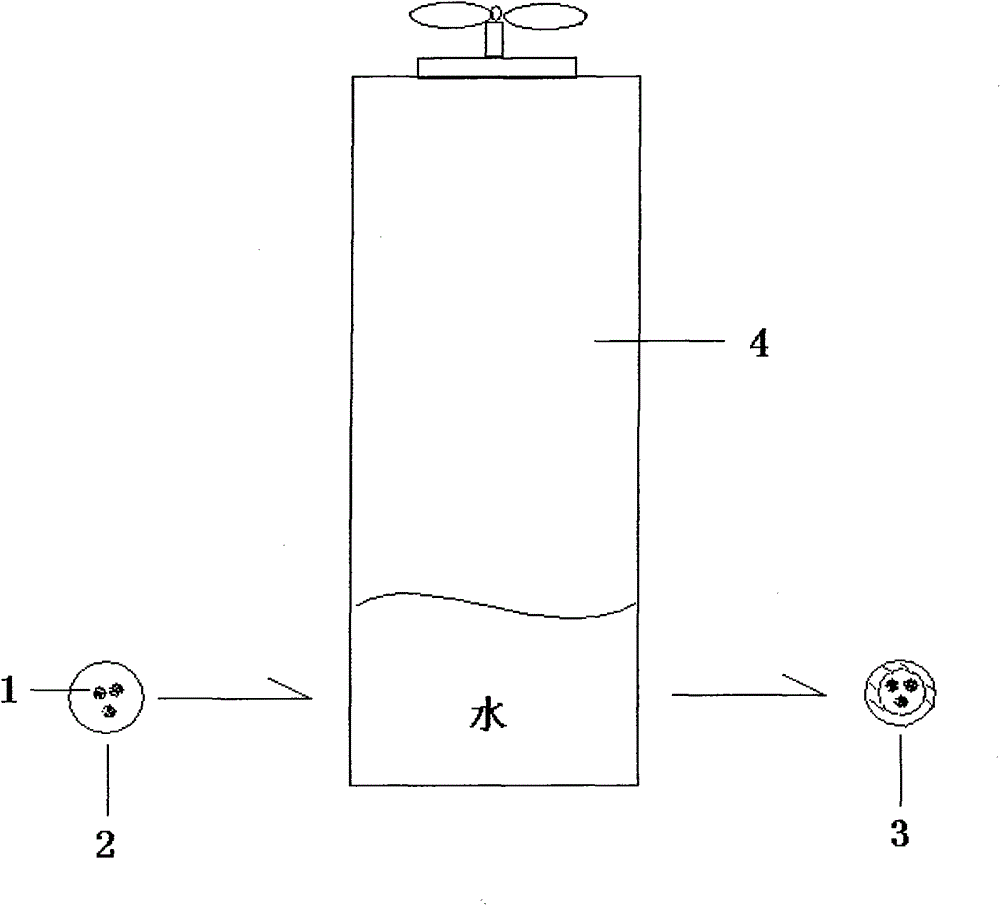

[0017] Get 0.02 g of the calcified sodium alginate gel beads (2) immobilized with the enzyme (1) prepared after freeze-drying and place them in a 10 ml supercritical carbon dioxide autoclave (4) and add 2 ml of deionized water to make the condensed The volume ratio of glue pellets to water is 1:2. Seal the reaction vessel, inject 10ml of supercritical carbon dioxide, keep the temperature of the system at 35°C and the pressure at 7.5MPa, and stir for 2 hours to react.

[0018] Take out the processed calcified sodium alginate-immobilized enzyme gel pellet (3) and put it into a 20ml beaker, add 3ml of deionized water, and then take 0.06mmol p-nitrophenol butyrate and drop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com