Friction power generator employing semiconductor composite material

A technology of triboelectric generators and composite materials, applied in the directions of triboelectric generators, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the above-mentioned semiconductor composite material will be described in detail below. The method includes: an optional step (1) modifying the metal particles, specifically using a modifier to treat the surface of the metal particles to obtain metal particles surface-modified by the modifier. The surface treatment method used in the present invention is a conventional metal particle surface treatment method.

[0060] (2) Prepare a liquid solution of the polymer base material. Specifically, polyvinylidene fluoride, polymethyl methacrylate or polyvinyl chloride are dissolved in dimethylacetamide (DMA) to form a liquid solution. Dimethicone itself is liquid and can be applied directly to the second step.

[0061] (3) Add metal particles to the liquid solution obtained in step (2) and mix well. When polydimethylsiloxane is used as the polymer, polydimethylsiloxane and curing agent (vulcanizing agent, usually at a ratio of 10:1) are required. Th...

Embodiment 1

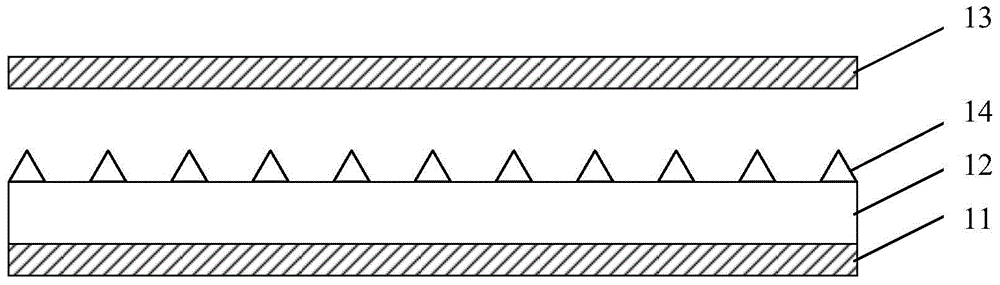

[0094] The size of the triboelectric generator is 3cm×3cm, and the total thickness is about 500μm. The triboelectric generator 1 includes a first electrode layer 11 , a first polymer material layer 12 , and a second electrode layer 13 which are stacked. The first polymer material layer 12 is a metal-doped polymer semiconductor composite material. The preparation method of the friction generator will be described in detail below.

[0095] 1. Preparation of semiconductor composite materials

[0096] 7.5 g of sodium lauryl sulfate was used to surface treat 25 g of silver particles (average volume particle diameter: 50 μm) to obtain metal particles surface-modified by modifiers. Add 5g of metal particles modified by the modifier surface and curing agent (Dow Corning 184) into 95g of polydimethylsiloxane (Dow Corning) to obtain a mixed slurry, in which polydimethylsiloxane and curing The mass ratio of agent is 10:1. The slurry is uniformly coated on the surface of the silicon t...

Embodiment 2

[0102] The size of the triboelectric generator is 3cm×3cm, and the total thickness is about 500μm. The triboelectric generator 1 includes a first electrode layer 11 , a first polymer material layer 12 , and a second electrode layer 13 which are stacked. The first polymer material layer 12 is a metal-doped polymer semiconductor composite material. The preparation method of the friction generator will be described in detail below.

[0103] 1. Preparation of semiconductor composite materials

[0104] 25 g of aluminum particles (average volume particle diameter: 50 μm) were surface-treated with 7.5 g of sodium lauryl sulfate to obtain metal particles surface-modified by modifiers. 5 g of the metal particles surface-modified by the modifier were added to a solution of polyvinylidene fluoride (95 g) in dimethylacetamide to obtain a mixed slurry. The slurry is evenly coated on the surface of the silicon template, and after a vacuum degassing process, excess slurry is removed by sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bump height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com