Titanium-sulfur powdery mildew prevention mixture

A powdery mildew and mixture technology, applied in pest control, biocide, fungicide, etc., can solve the problems of destroying protease activity, reducing respiratory function, pesticide residue, etc., and achieve the effect of increasing photosynthesis, reducing loss, and strengthening nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

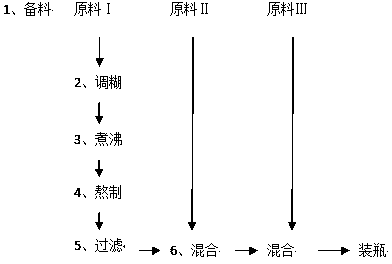

[0016] Attached below figure 1 Describe in detail the composition and preparation method of a nano-titanium rice planthopper control agent

[0017] 1. Raw material preparation: raw material I is 1,000 g of sulfur powder, raw material II is 500 g of nano-titanium microspheres with a shell-core structure, and raw material III is 5 kg of high-fat film;

[0018] 2. Mix raw material I with warm water at 40-50°C to make a paste;

[0019] 3. After step 2) is further made into a paste, add 6 kg of water, boil over high heat until it boils, and start timing for 10 minutes;

[0020] 4. After further completion of step 3), turn the heat to simmer and cook for 40-60 minutes. Keep stirring during the cooking to avoid burning until the liquid turns brown, then turn off the heat, and place it in a ventilated place to cool down naturally to 40-45°C;

[0021] 5. After step 4) is completed, filter out the residue with gauze;

[0022] 6. After step 5) is completed, add the nano-titanium micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com