Compound mulberry leaf Fuzhuan brick tea and production method thereof

A technology of Fu brick tea and mulberry leaf, applied in the field of tea and its preparation, can solve the problems of low input and output, public description of mulberry leaf raw material black tea and mulberry leaf Fu brick tea, and high construction cost of high-quality dark tea raw material base, and achieves an increase in The effect of pine smoke fungus incense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

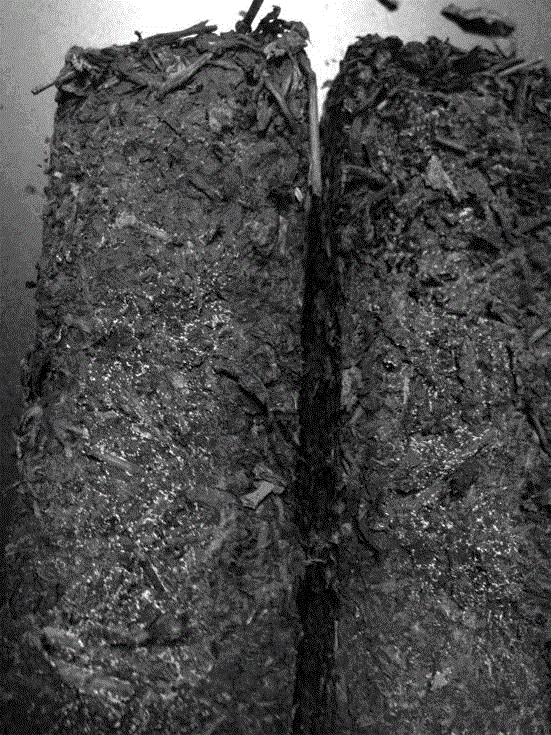

Image

Examples

Embodiment 1

[0044] Select the mulberry leaves of "Xiang 7920" as the mulberry tree variety,

[0045] (1) Picking mulberry leaves in different seasons and grades: pick the first-level leaves in spring, that is, the top buds to the third leaf position without pesticide pollution, no pests and diseases, and bulk in bamboo baskets;

[0046] (2) Greening and watering: spread the mulberry leaves on a bamboo sieve with a thickness of 3 cm, room temperature 25°C, time 60 minutes, fan blowing until lightly withered, before finishing greening, sprinkle 5% of the fresh leaves with water, while sprinkling Mix, dip both sides of the mulberry leaves with water to prevent burnt edges;

[0047] (3) Fixing: Use 6CST-50 drum-type grinding machine, the core temperature is 110°C, and the time is 2.5 minutes, so that the leaves are soft and slightly sticky, the veins are folded and continuous, the leaf color becomes dark green, and the surface is dull. The green odor disappears, the fragrance appears, and th...

Embodiment 2

[0060] Select the mulberry tree variety as the mulberry leaves of "Nongsang No. 12",

[0061] (1) Picking mulberry leaves in different seasons and grades: in mid-autumn, the first, second and third grades are picked without pesticide pollution, no pests and diseases, no scorched edges, and packed in bamboo baskets. Make one, two, and three grades of mulberry leaf raw material tea respectively; wherein the first and third grades of mulberry leaf raw material tea are completed according to the steps (1) to (6) of Embodiment 1 and Embodiment 3 respectively, and the second grade of mulberry leaf raw material tea is as follows The above steps are completed;

[0062] (2) Greening and watering: autumn leaves do not need to be greened, and water should be sprinkled according to 15% of the amount of fresh leaves before killing, and mixed while sprinkling, and both sides of mulberry leaves are wet to prevent burnt edges after finishing;

[0063] (3) Fixing: Use 6CST-70 drum-type grindi...

Embodiment 3

[0076] Select the mulberry leaves of "Yu 711" as the mulberry variety,

[0077] (1) Picking mulberry leaves in different seasons and grades: picking tertiary leaves in summer, that is, mulberry leaves without pesticide pollution, diseases and insect pests below the eighth leaf position, and packed in bamboo baskets;

[0078] (2) Greening and watering: Summer leaves do not need to be greened, and water should be sprinkled according to 15% of the amount of fresh leaves before killing, and mixed while sprinkling, and both sides of the mulberry leaves are wet to prevent burnt edges after killing;

[0079] (3) Fixing: Use 6CST-55 drum-type grinding machine, core temperature 170 ° C, time 5 minutes, so that the leaves are soft and slightly sticky, the veins are broken and continuous, the leaf color becomes dark green, the surface is dull, and the green smell The gas disappears, the fragrance appears, and the water content of the green leaves is 48%;

[0080] (4) Kneading: Do not le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com