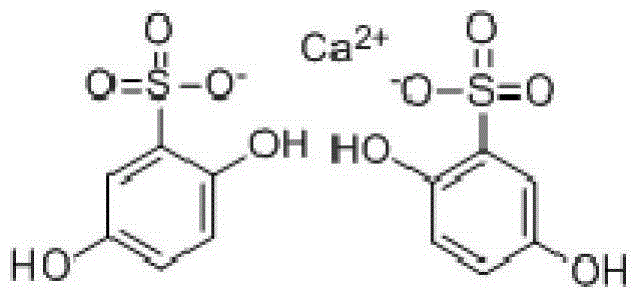

Calcium dobesilate capsule

A technology of calcium dobesilate and capsules, applied in the directions of capsule delivery, anhydride/acid/halide active ingredients, metabolic diseases, etc., can solve problems such as poor uniformity, oxidative deterioration of calcium dobesilate capsules, etc. The effect of reducing the amount of excipients, ensuring consistency and biological efficacy, improving properties and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

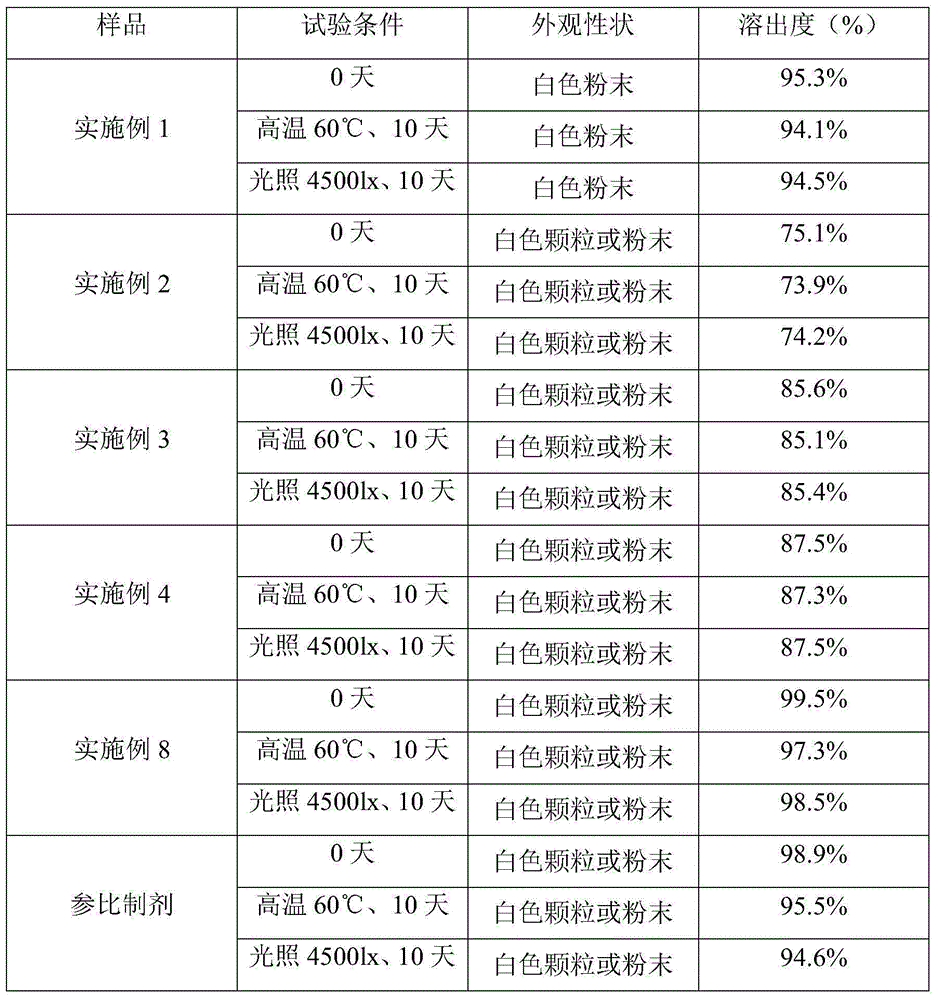

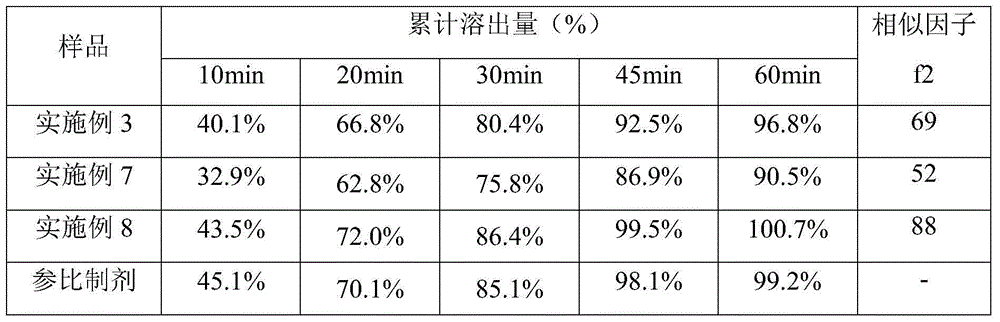

Embodiment 1

[0032] Conventional method: powder direct filling meter, 1000 capsules

[0033] Get calcium dobesilate 521.5g, starch 25g, magnesium stearate 5g, pulverize and pass through a 60-mesh sieve. First, mix calcium dobesilate and starch (the amount weighed is added without specifying the quantity, the same below), then add magnesium stearate and mix well, and then fill the capsules with an automatic capsule filling machine to obtain hydroxybenzenesulfonate Calcium sulfonate capsules.

Embodiment 2

[0035] The invention provides a method, dry granulation, calculated in 1000 grains

[0036] Get calcium dobesilate 521.5g, starch 25g, magnesium stearate 5g, pulverize and pass through a 60-mesh sieve. First mix calcium dobesilate and starch, dry granulate; then add magnesium stearate and mix evenly, fill capsules with an automatic capsule filling machine to obtain calcium dobesilate capsules.

Embodiment 3

[0038] The invention provides a method, dry granulation, calculated in 1000 grains

[0039] Get calcium dobesilate 521.5g, starch 25g, sodium carboxymethyl starch 25g, magnesium stearate 5g, pulverize and pass through a 40-mesh sieve. First mix calcium dobesilate, starch and 15g sodium carboxymethyl starch, and dry granulate; then add magnesium stearate and the remainder of 10g sodium carboxymethyl starch, mix well, and fill the capsules with an automatic capsule filling machine , to obtain calcium dobesilate capsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com