Polysulfonate separation membrane and preparation method thereof

A technology of polysulfone and separation membranes, which is applied in the field of separation membranes, can solve the problems that the membrane performance is difficult to be significantly improved, and the structure of wet-process membranes is difficult to control, etc., and achieves the effects of easy industrial scale production, low-cost realization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

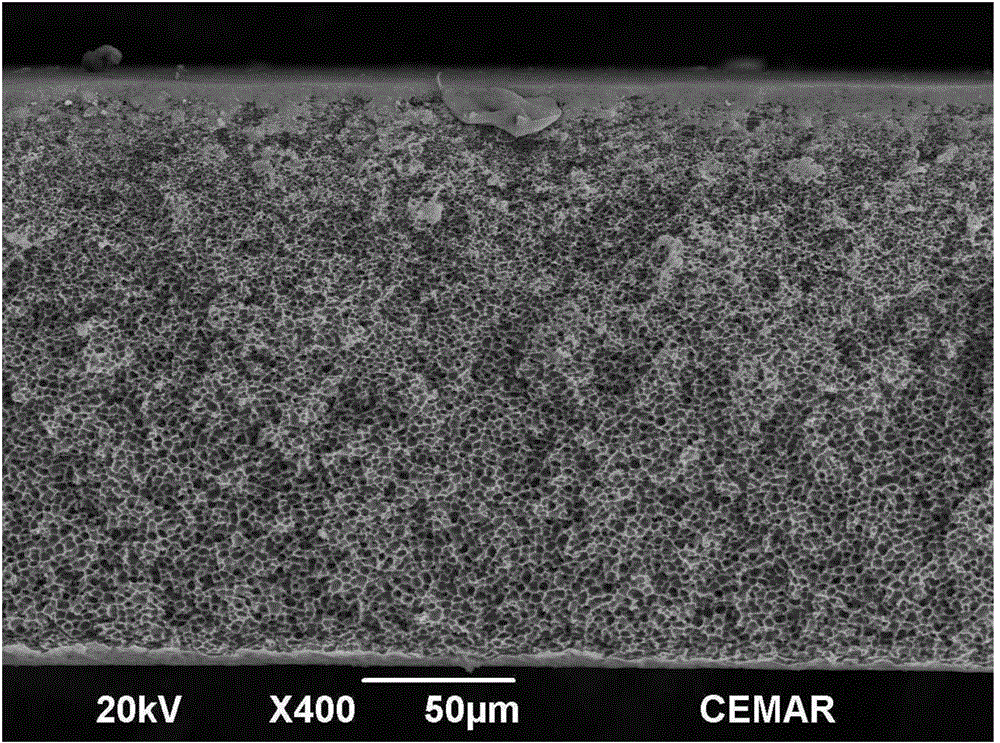

Image

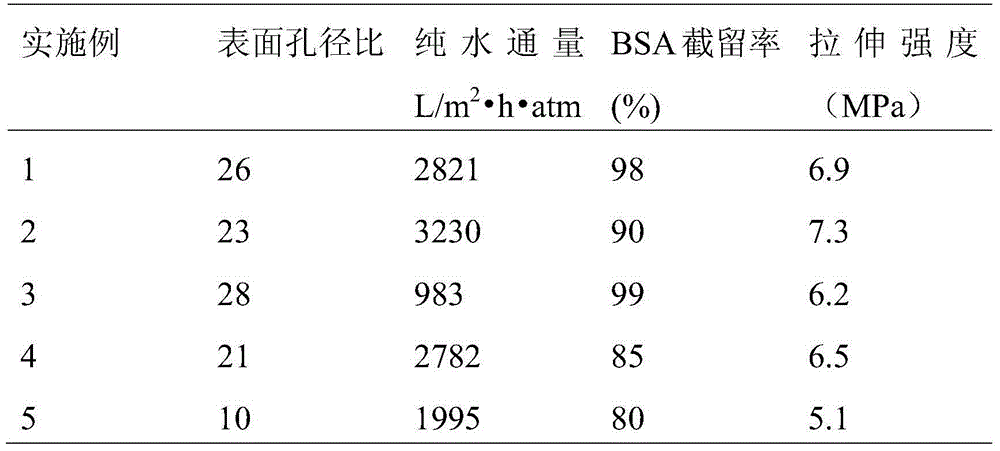

Examples

Embodiment 1

[0036] Mix the mixture of polyethersulfone, dimethylformamide, acetic acid and glycerin (the mass ratio of acetic acid and glycerol is 1:1) and PVPK30 according to the mass ratio of 15:60:12:13, and stir in an oil bath at 85°C for 24 Hours to prepare a clear and transparent solution, reduce the stirring speed and continue to stir for 2 hours to defoam. Control the humidity of the scraping film atmosphere to be stable at 55%, set the gap between the blades of the flat-panel scraping machine to 0.2 microns, spread the prepared casting solution on the side of the glass substrate, start the flat-panel scraping machine, and set the scraper at a speed of 100mm / s Speed operation, after the scraper stops running, stay in the air for 25s, and then transfer to 0.1mol / L sodium bicarbonate aqueous coagulation bath to prepare polyethersulfone flat membrane, rinse in pure water for 48 hours, every 2 -Change the water once every 5 hours, then soak in a mixed solution of NaOH, citric acid a...

Embodiment 2

[0038] Mix polysulfone, dimethylacetamide, and PEG6000 at a mass ratio of 18:68:15, stir in an oil bath at 60°C for 24 hours to prepare a clear and transparent solution, reduce the stirring speed and continue stirring for 2 hours to defoam, then add dropwise Hydrochloric acid until the pH of the casting solution is between 4-5, at this time the mass ratio of polysulfone, dimethylacetamide, PEG6000, and hydrochloric acid in the casting solution is 17:66:14:3. Control the humidity of the scraping film atmosphere to be stable at 100%, set the gap between the blades of the flat-panel film-hanging machine to 0.5 microns, spread the prepared casting liquid on the side of the glass substrate, start the flat-panel film-scraping machine, and the scraper at a speed of 100mm / s Speed operation, after the scraper stops running, stay in the air for 1min, then transfer to 0.1mol / L sodium bicarbonate aqueous coagulation bath, prepare polyethersulfone flat membrane, rinse in pure water for 48...

Embodiment 3

[0040] Mix polyethersulfone, methylpyrrolidone, and butyric acid in a mass ratio of 20:75:5, stir in an oil bath at 30°C for 24 hours to prepare a clear and transparent solution, reduce the stirring speed and continue stirring for 2 hours to defoam, and then transfer to the cast film Add isopropanol drop by drop to the solution, and monitor the viscosity change of the casting solution in real time, stop adding until the viscosity of the casting solution reaches a minimum value, at this time, polyethersulfone, methylpyrrolidone, butyric acid and The mass ratio of propanol is 17:66:5:12. Control the humidity of the scraping film atmosphere to be stable at 55%, set the gap between the blades of the flat-panel scraping machine to 0.2 microns, spread the prepared casting solution on the side of the glass substrate, start the flat-panel scraping machine, and set the scraper at a speed of 100mm / s Run at high speed, transfer to 0.1mol / L sodium bicarbonate aqueous coagulation bath imme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com