Method of etching surface topography of polydimethylsiloxane (PDMS) by oxygen plasmas

A polydimethylsiloxane, oxygen plasma technology, which is applied in the process of producing decorative surface effects, decorative arts, gaseous chemical plating, etc., can solve the problem of high cost, unsuitable for mass production, and cumbersome process. and other problems, to achieve the effect of low cost, easy operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method utilizing oxygen plasma to etch the surface topography of polydimethylsiloxane, comprising the following steps:

[0022] Step 1, using adhesive tape to stick off the paint protection layer on the top layer of the CD to obtain a CD template with a regular microstructure;

[0023] Step 2, after mixing the PDMS prepolymer and the crosslinking agent at a mass ratio of 10:1, fully stir with a glass rod to form a uniform prepolymer;

[0024] Step 3. After degassing the mixed prepolymer in a circulating water multi-purpose vacuum pump, pour it on the surface of the CD template prepared in step 1, and heat it at 80 degrees Celsius for 3 hours for crosslinking;

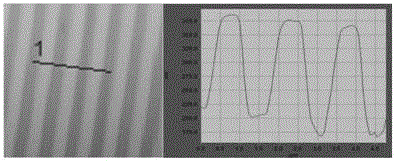

[0025] Step 4. Slowly peel off the PDMS from the CD template to obtain a PDMS stamp with a negative microstructure of the CD template. The surface morphology is as follows: figure 1 as shown, figure 1 For the atomic force diagram, the height of the PDMS stamp is 170nm;

[0026] Step 5: Cut the PDMS stamp pre...

Embodiment 2

[0028] A method utilizing oxygen plasma to etch the surface topography of polydimethylsiloxane, comprising the following steps:

[0029] Step 1, using adhesive tape to stick off the paint protection layer on the top layer of the CD to obtain a CD template with a regular microstructure;

[0030] Step 2, after mixing the PDMS prepolymer and the crosslinking agent at a mass ratio of 20:1, fully stir with a glass rod to form a uniform prepolymer;

[0031] Step 3. After degassing the mixed prepolymer in a circulating water multi-purpose vacuum pump, pour it on the surface of the CD template prepared in step 1, and heat it at 60 degrees Celsius for 4 hours for crosslinking;

[0032] Step 4, slowly peel off the PDMS from the CD template to obtain a PDMS stamp with a negative microstructure of the CD template;

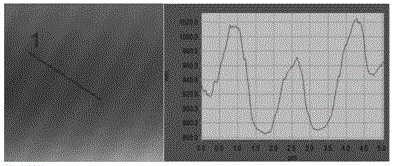

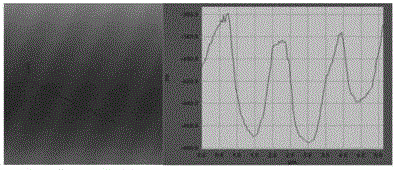

[0033] Step 5: Cut the PDMS stamp prepared above into a square, place it in an oxygen plasma atmosphere, and etch the PDMS stamp for 20 minutes. The height of the microstruc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com