Processing device and processing method for cutting sapphire glass by utilizing infrared laser

A sapphire glass, infrared laser technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of large sapphire edge micro-cracks, expensive lasers, low laser power, etc., to solve the problems of efficiency and effect, Reduce edge chipping, heat-affected area, and small flare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

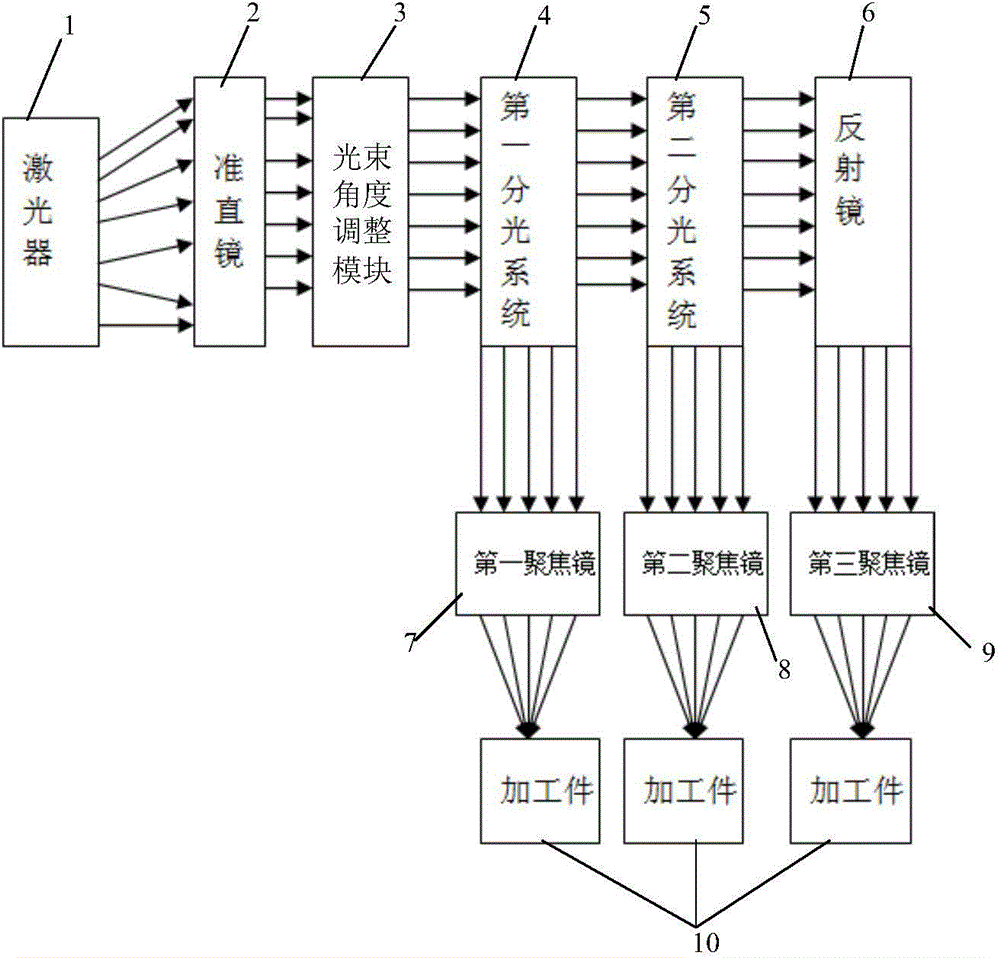

[0021] Such as figure 1 As shown, the processing device for infrared laser cutting sapphire glass includes a laser 1, a collimator 2, a beam angle adjustment module 3, and a first beam splitting system 4 arranged sequentially along the optical path. The laser 1 is a 1070±10nm fiber pulse laser, and the first The output end of the spectroscopic system 4 is arranged with a first focusing mirror 7 and a second spectroscopic system 5, the output end of the second spectroscopic system 5 is arranged with a second focusing mirror 8 and a reflector 6, and the output end of the reflector 6 is arranged with a third The focusing mirror 9, the first focusing mirror 7, the second focusing mirror 8 and the third focusing mirror 9 are facing the three-dimensional platform for placing sapphire glass, and a high-resolution auxiliary positioning imaging system is arranged above the three-dimensional platform, and the high-resolution auxiliary positioning The imaging system consists of industria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com