Sintering method of light sintered shale brick with rectangular openings

A sintering method and technology of shale bricks, which can be applied to clay products, other household utensils, household utensils, etc., can solve the problems of missing corners and cracks, high construction technology requirements, and easy deformation, etc., and achieve good weather resistance, Good thermal insulation effect and sound insulation effect, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

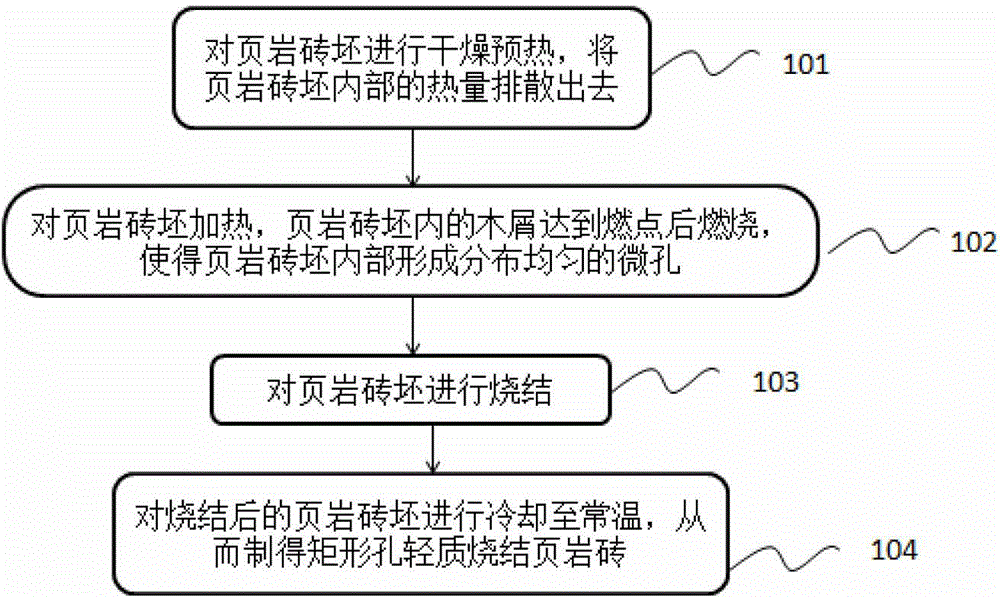

[0021] see figure 1 , is a schematic flow chart of the sintering method of the present invention. A preferred embodiment of the present invention provides a method for sintering rectangular hole lightweight sintered shale bricks, which includes the following steps:

[0022] Step 101. Drying and preheating the shale bricks to dissipate the heat inside the shale bricks; during the preheating process, by slowly raising the temperature to ensure that the shale bricks form a better heat transfer path during the drying and preheating stage, The heat inside the shale adobe can be dissipated in time, so that the shale adobe will not form a large temperature stress difference and cause more cracks in the adobe;

[0023] Step 102. Heat the shale bricks, burn the sawdust in the shale bricks after reaching the ignition point, so that evenly distributed micropore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com